A kind of preparation method of bean curd with high yield and no beany smell

A technology of beany smell and yield, applied in the field of food processing, can solve the problems of high water content of tofu, reduce beany smell, easy to break, etc., and achieve the effects of reducing protein content, improving dissolution effect, and eliminating bitterness and astringency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

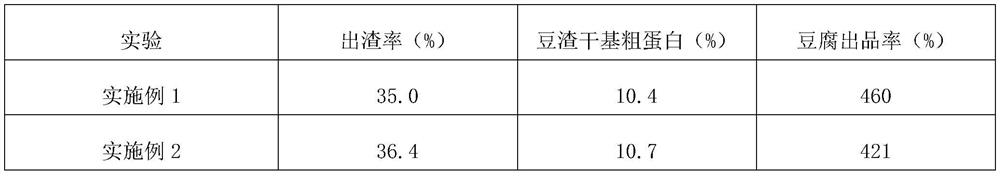

Embodiment 1

[0026] A preparation method of tofu with high yield and no beany smell, comprising the steps as follows:

[0027] 1) Soybean selection: choose soybean moisture content of 12.5% and dry basis protein content of 44%;

[0028] 2) Drying: the soybean is treated by vacuum microwave drying method for 3 minutes, so that the moisture content of the soybean after drying is 9.5%, the vacuum microwave intensity is 8w / g, and the vacuum degree is 85KPa.

[0029] 3) crushing: the dried soybean is mechanically crushed to 6 pieces, and the bean skin and bean navel are removed by wind selection;

[0030] 4) Softening: Use indirect steam to soften the crushed soybeans in a step-wise manner. The first softening temperature is 75°C and the softening time is 5 minutes. After the first softening, the softening interval is 3 minutes. After softening, the second softening is performed. The second softening temperature is 87°C. , The secondary softening time is 10min.

[0031] 5) embryo rolling: t...

Embodiment 2

[0037] A preparation method of tofu with high yield and no beany smell, comprising the steps as follows:

[0038] 1) Soybean selection: choose soybean moisture 12.0%, dry basis protein content 43.2%;

[0039]2) Drying: The soybean is treated by vacuum microwave drying method for 5 minutes, so that the moisture content of the soybean after drying is 8.5%, the vacuum microwave intensity is 8w / g, and the vacuum degree is 85KPa.

[0040] 3) crushing: the dried soybeans are mechanically crushed to 8 lobes, and the bean skin and bean navel are removed by wind selection;

[0041] 4) Softening: use indirect steam to soften the crushed soybeans in a stepwise manner, the first softening temperature is 70 ° C, the softening time is 8 minutes, the softening interval is 3 minutes after the first softening, and the second softening is performed after the softening, and the second softening temperature is 75 ° C. , The secondary softening time is 50min.

[0042] 5) Embedding: the crushed w...

Embodiment 3

[0048] A preparation method of tofu with high yield and no beany smell, comprising the steps as follows:

[0049] 1) Soybean selection: select soybean moisture 10.7%, dry basis protein content 43.5%;

[0050] 2) Drying: the soybean is treated by vacuum microwave drying method for 5 minutes, so that the moisture content of the soybean after drying is 9.05%, the vacuum microwave intensity is 8w / g, and the vacuum degree is 82KPa.

[0051] 3) crushing: the dried soybean is mechanically crushed to 4 pieces, and the bean skin and bean navel are removed by wind selection;

[0052] 4) Softening: use indirect steam to soften the crushed soybeans in a step-wise manner. The primary softening temperature is 73°C and the softening time is 20 minutes. After the primary softening, the softening interval is 3 minutes. After softening, the secondary softening is performed. The secondary softening temperature is 81°C. , The secondary softening time is 21min.

[0053] 5) embryo rolling: the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com