Hulling assembly special for novel oil camellia huller

A technology of shelling machine and Camellia oleifera, which is applied in the direction of shelling, application, fat oil/fat production, etc. It can solve the problems of high tea seed damage rate, shortened storage time of camellia oleifera seeds, and affect the quality of camellia oleifera, so as to improve the efficiency of shelling, Avoid the effect of seed damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

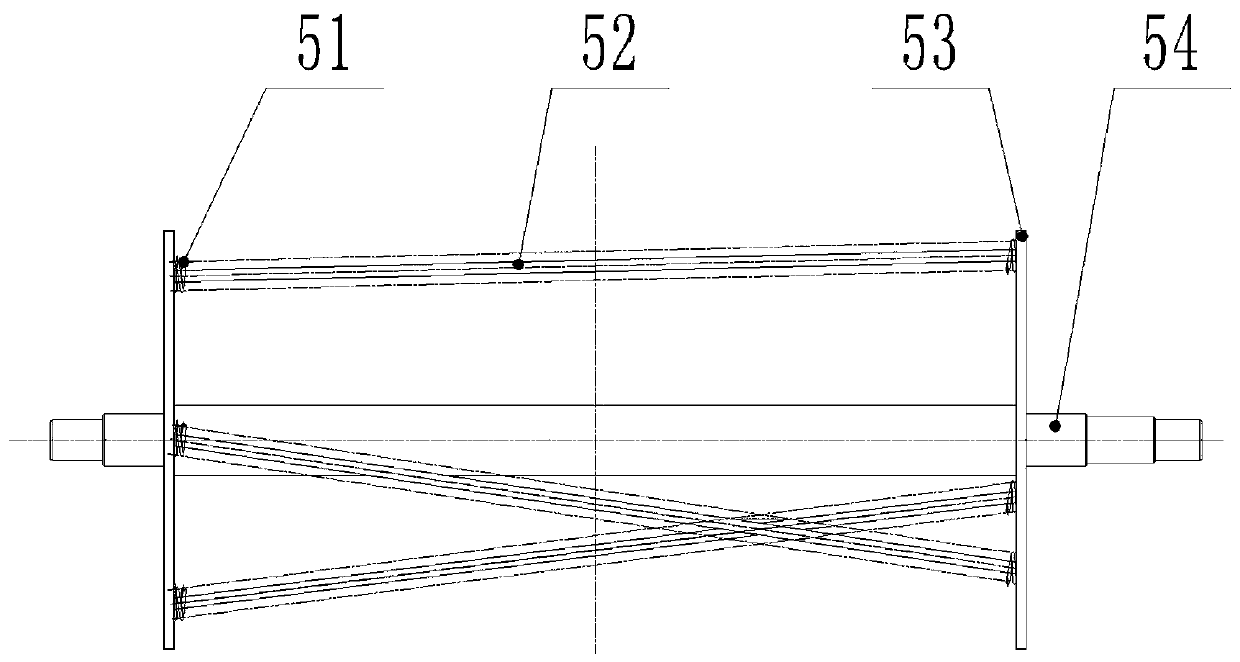

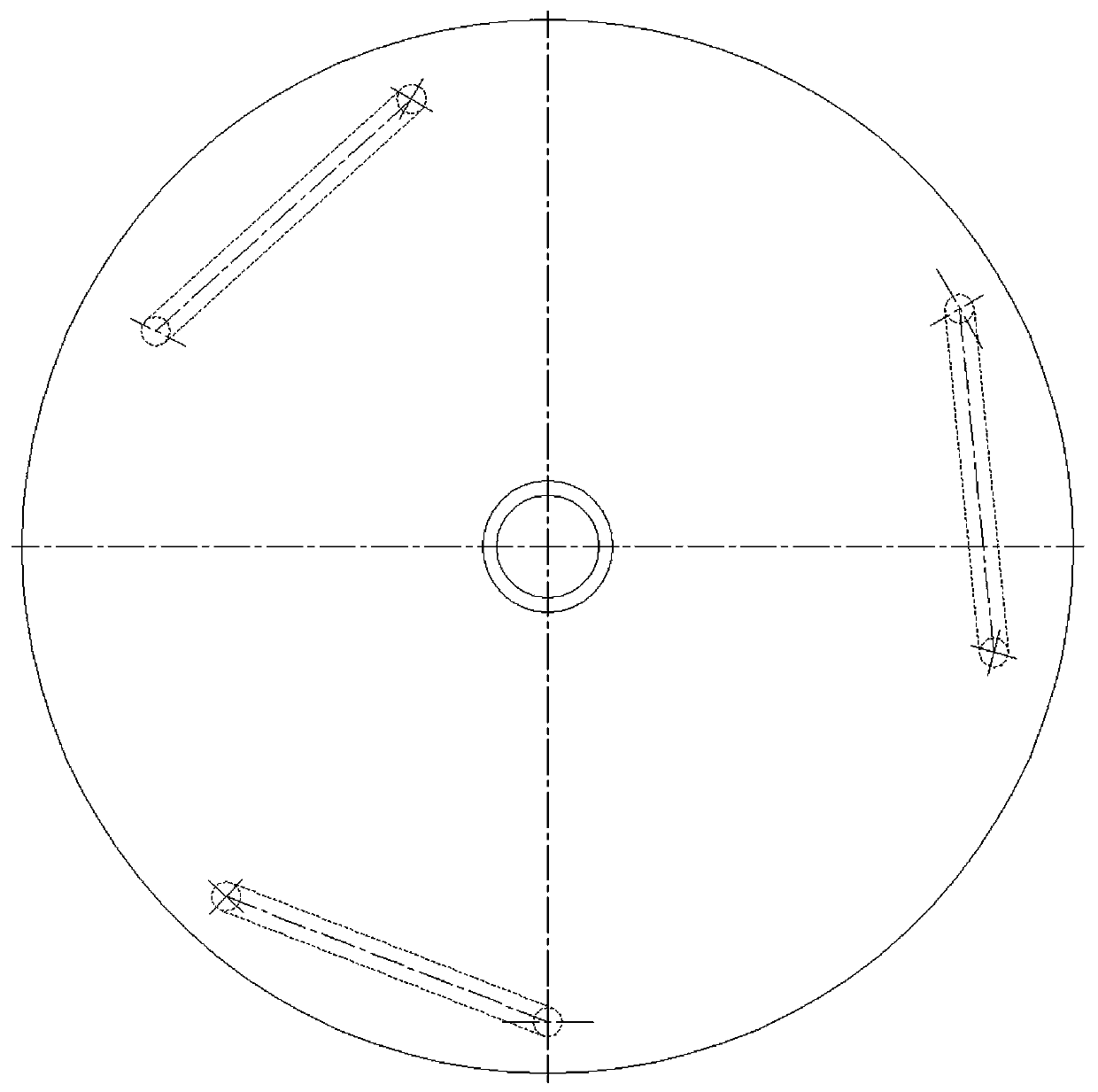

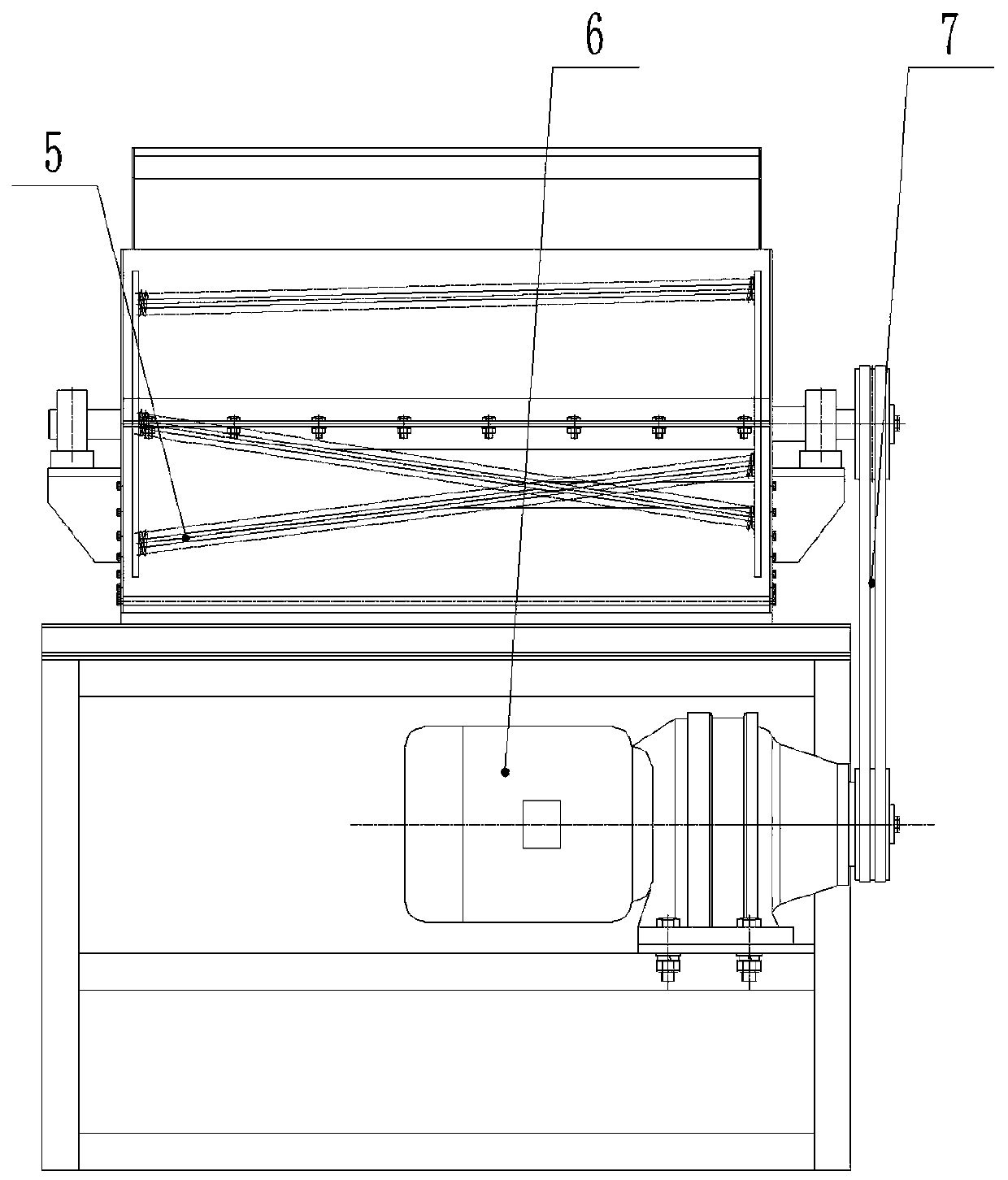

[0017] Embodiment 1, refer to Figure 1 to Figure 2 , the two side baffles 53 are arranged in parallel, the drive shaft 54 passes through the center of the two side baffles 53, and three sets of rods 52 are fixedly installed between the two sides of the baffles 53, and the three sets of rods 52 are clockwise along the circumference of the side baffles 53 direction or anticlockwise deflection uniform distribution, 3 sets of rods 52 form 6 connection points with the baffles 53 on both sides, and the distances between the 6 connection points and the outer edge of the side baffles 53 are not the same, each sleeve rod 52 along the side The circumferential deflection distance of the baffle plate 53 and the radial deflection distance along the side baffle plate 53 are also different. By arranging the sleeve rod in this way, the size of the gap formed between the whole shelling assembly and the feed bin is different, which can adapt to camellia oleifera seeds with various particle s...

Embodiment 2

[0018] Embodiment 2, refer to Figure 1 to Figure 2 , the outside of the sleeve rod 52 is covered with a spring 51, there is a gap between the sleeve rod 52 and the spring 51, the width of the gap is not less than the diameter of the sleeve rod 52, forming an elastic accommodation space, which can adapt to camellia oleifera seeds with different particle sizes, and in Camellia oleifera seeds with larger particle size form a rebound force under pressure, forcing the camellia oleifera seeds to move to a larger gap, which can avoid seed damage and jamming. All the other are with embodiment 1.

Embodiment 3

[0019] Embodiment 3, refer to Figure 1 to Figure 2 , the sleeve rods 52 are provided with three, and the distances between each sleeve rod 52 and the outer edges of the baffle plates 53 on both sides are 10mm / 5mm, 15mm / 10mm, and 20mm / 15mm respectively. All the other are the same as above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com