Method for grinding sample cross section

A grinding method and sample technology, applied in the preparation of test samples, grinding devices, grinding machine tools, etc., can solve the problems of small samples being difficult, unable to correct micro-samples, and difficult to obtain expected results, and achieve increased area and thickness. , the effect of simplifying the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

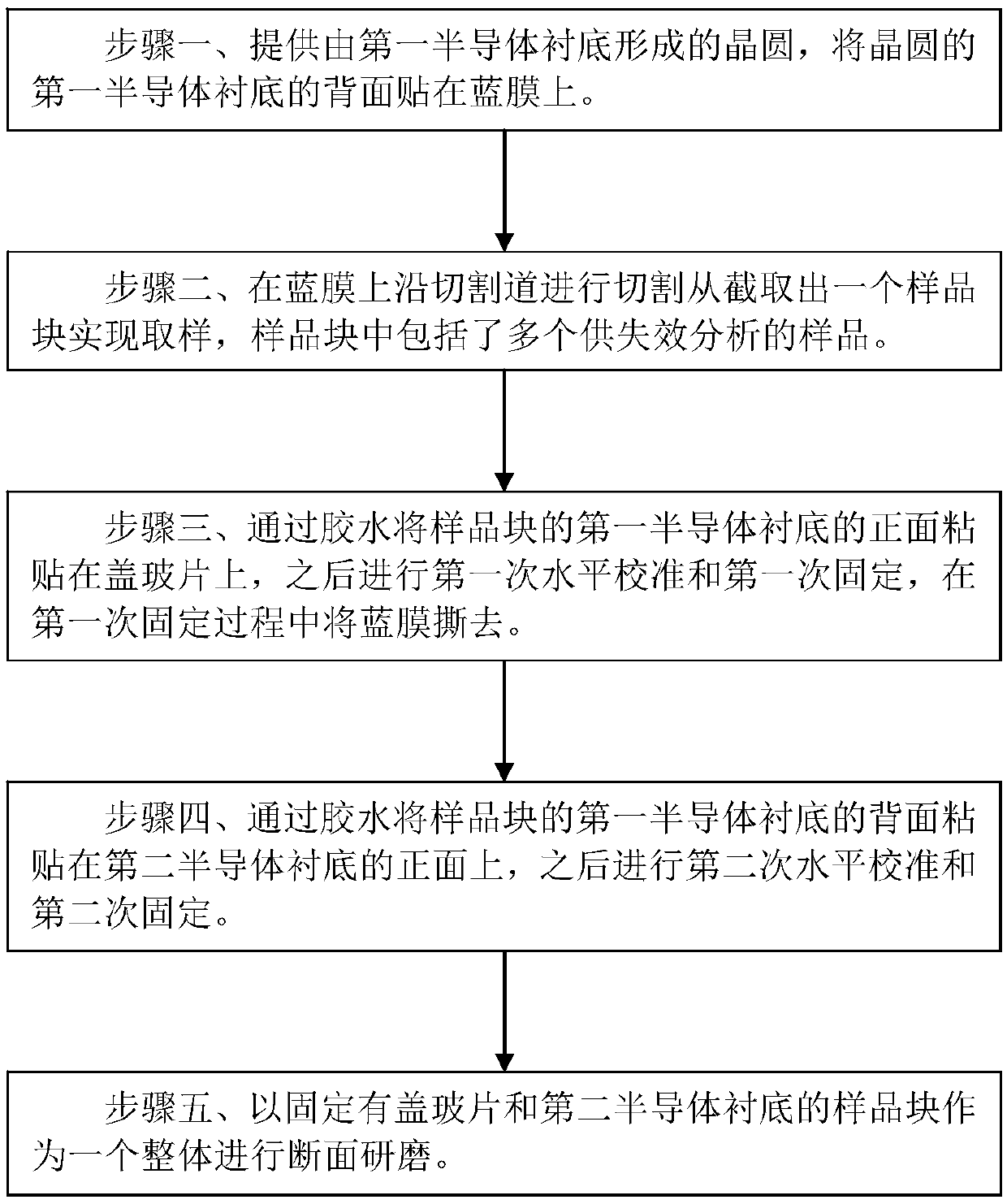

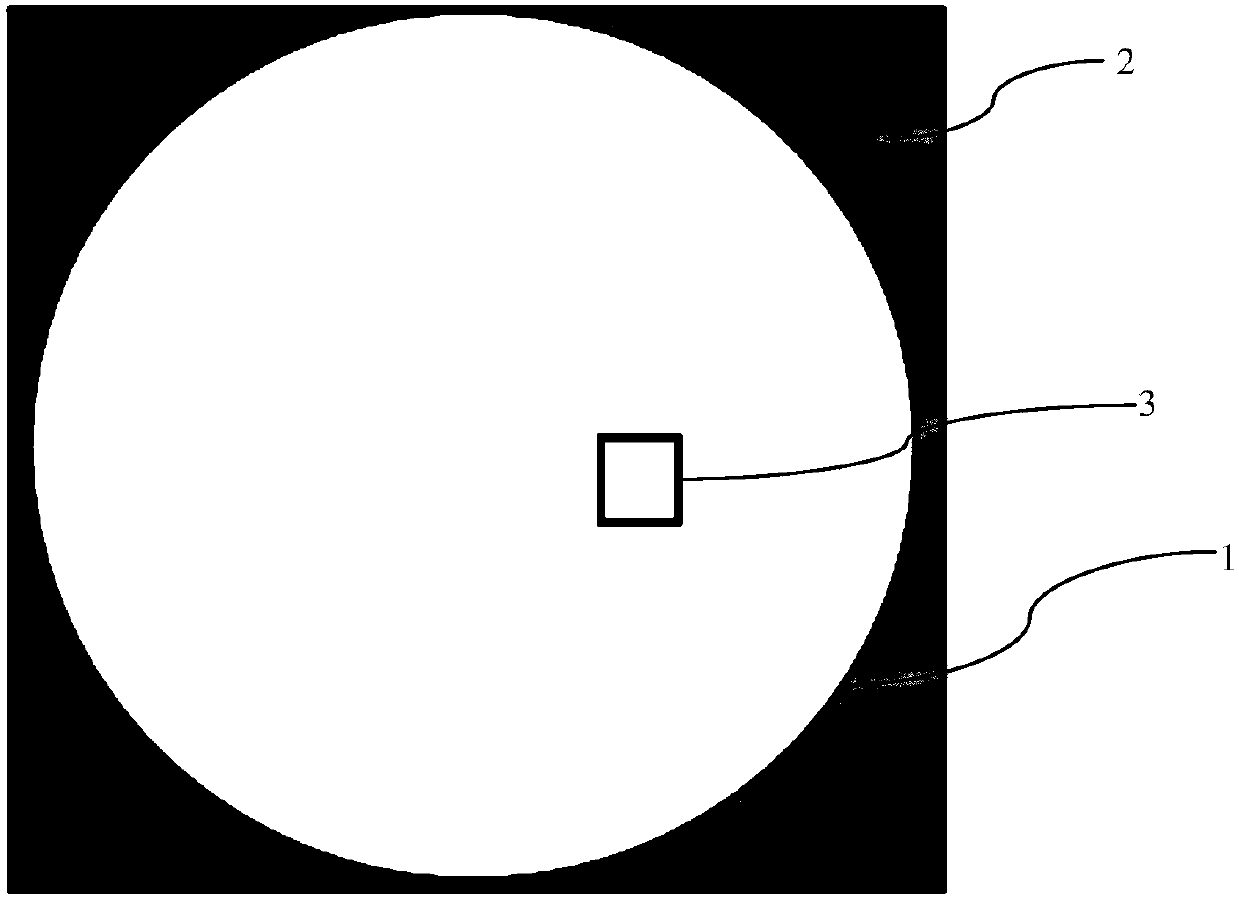

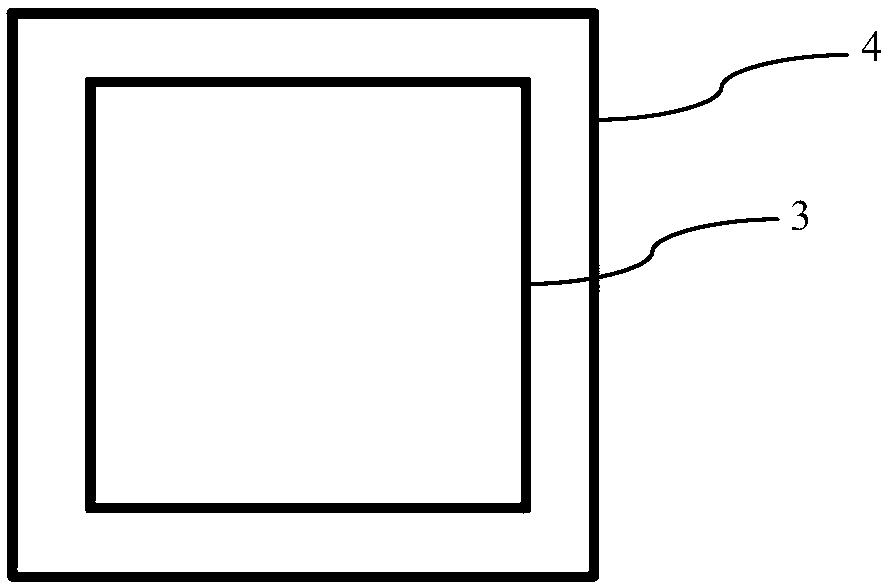

[0031] Such as figure 1 Shown is the flow chart of the cross-section grinding method of the sample of the embodiment of the present invention; Figure 2A to Figure 2D Shown is the schematic diagram of the structure in each step of the method of the embodiment of the present invention, the cross-section grinding method of the sample of the embodiment of the present invention comprises the following steps:

[0032] Step 1, such as Figure 2A As shown, a wafer formed by a first semiconductor substrate 1 is provided, on which a chip is formed, and a plurality of samples needing cross-section grinding are provided on the wafer, and each of the samples is used for failure analysis ; Paste the back side of the first semiconductor substrate 1 of the wafer on the blue film 2 ;

[0033] In the method of the embodiment of the present invention, the first semiconductor substrate 1 is a silicon substrate,

[0034] Step two, such as Figure 2A As shown, sampling is carried out, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com