Carbon dioxide gas spraying device and positioning mechanism thereof

A jet device, carbon dioxide technology, applied in metal processing and other directions, can solve the problems of high labor cost, heavy workload of workers, unable to meet processing requirements, etc., to achieve the effect of speeding up discharge efficiency, ensuring quality, and reducing airflow rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

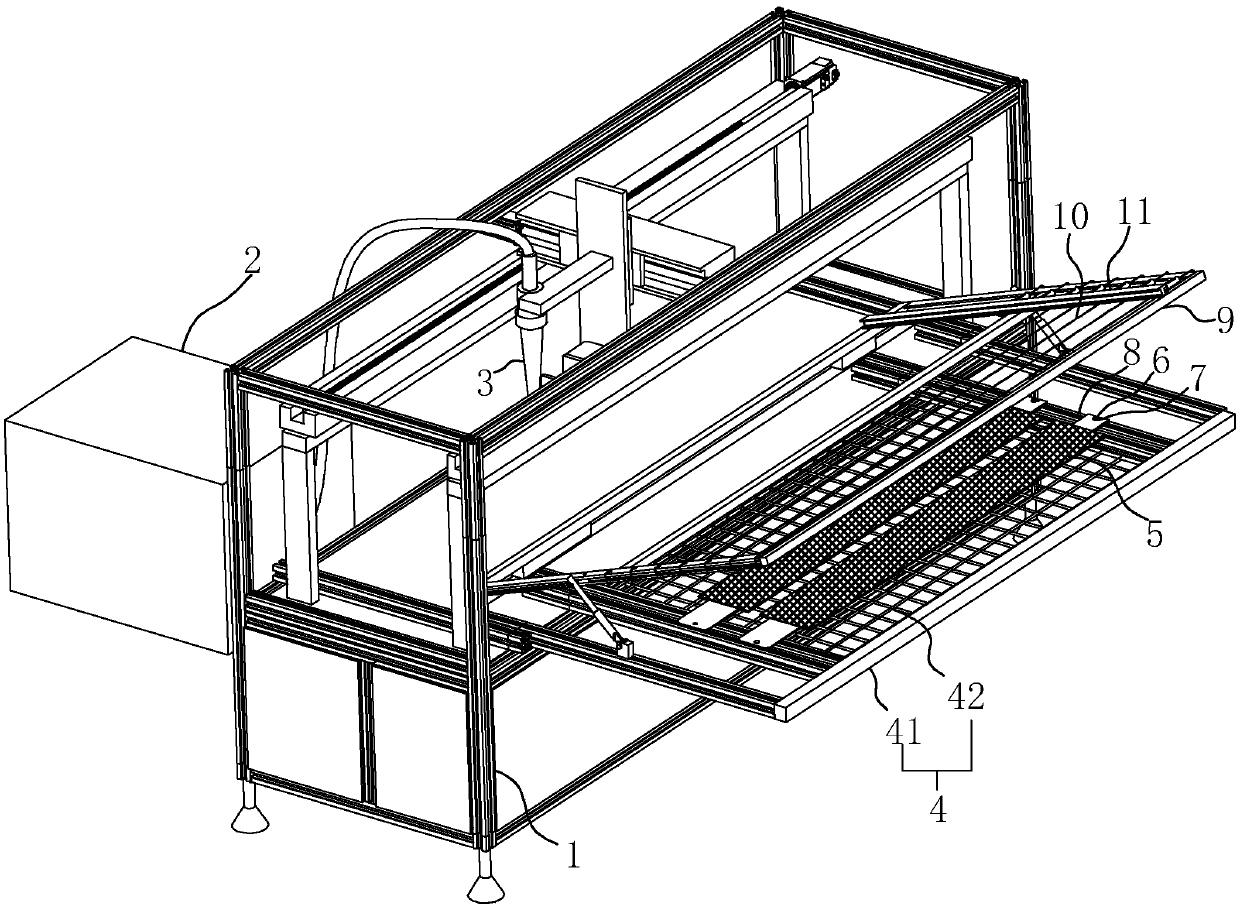

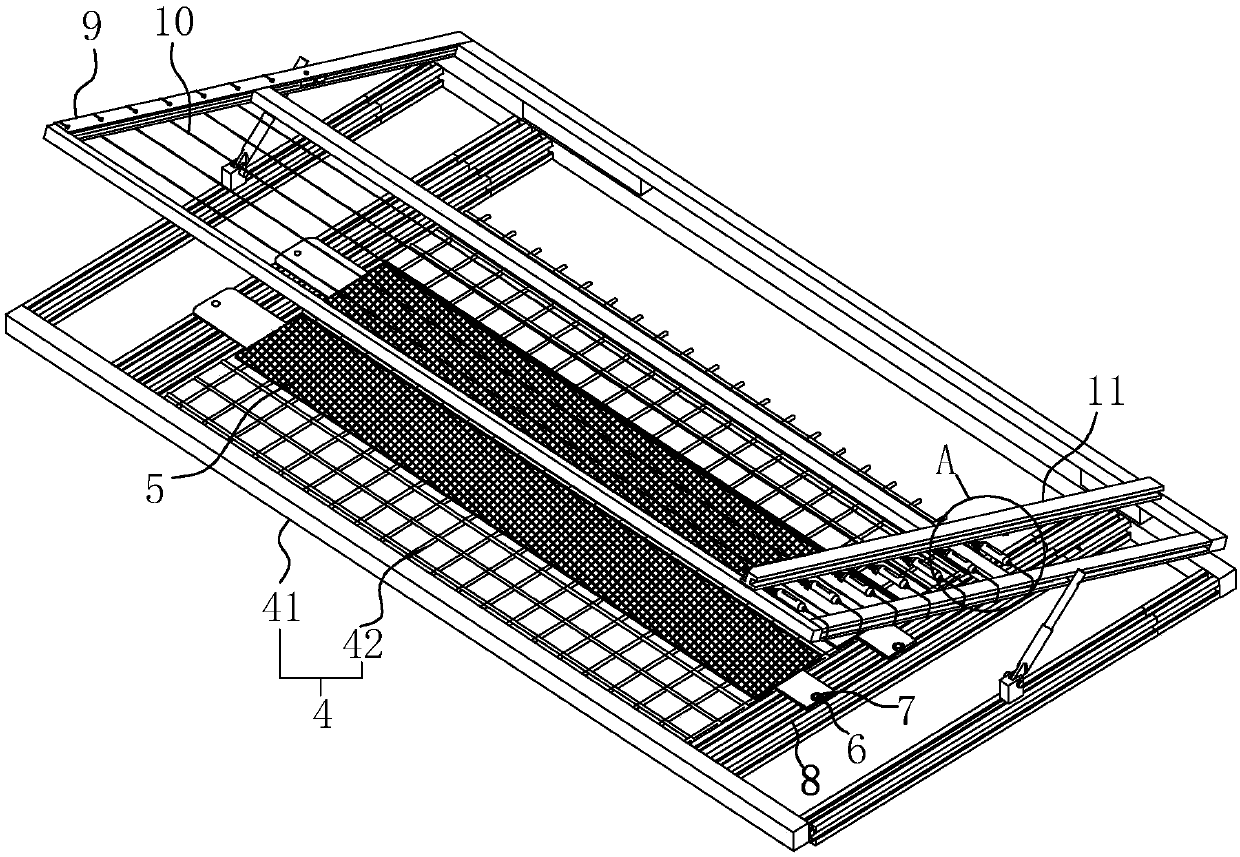

[0034] A carbon dioxide sparging device such as figure 1 with figure 2 As shown, it includes a body 1, a dry ice blaster 2 and a nozzle 3. The body 1 is provided with a workbench 4, and the workbench 4 is provided with a positioning mechanism for positioning the jeans to be processed, so that the carbon dioxide gas is provided by the dry ice blaster 2 and then Spray on the jeans on the workbench 4 with the help of the nozzle 3 to achieve a damaged shape on the surface of the jeans, wherein the position of the nozzle 3 can be adjusted along the horizontal and vertical directions, so that the desired shape can be printed on the jeans according to actual needs. Broken pattern.

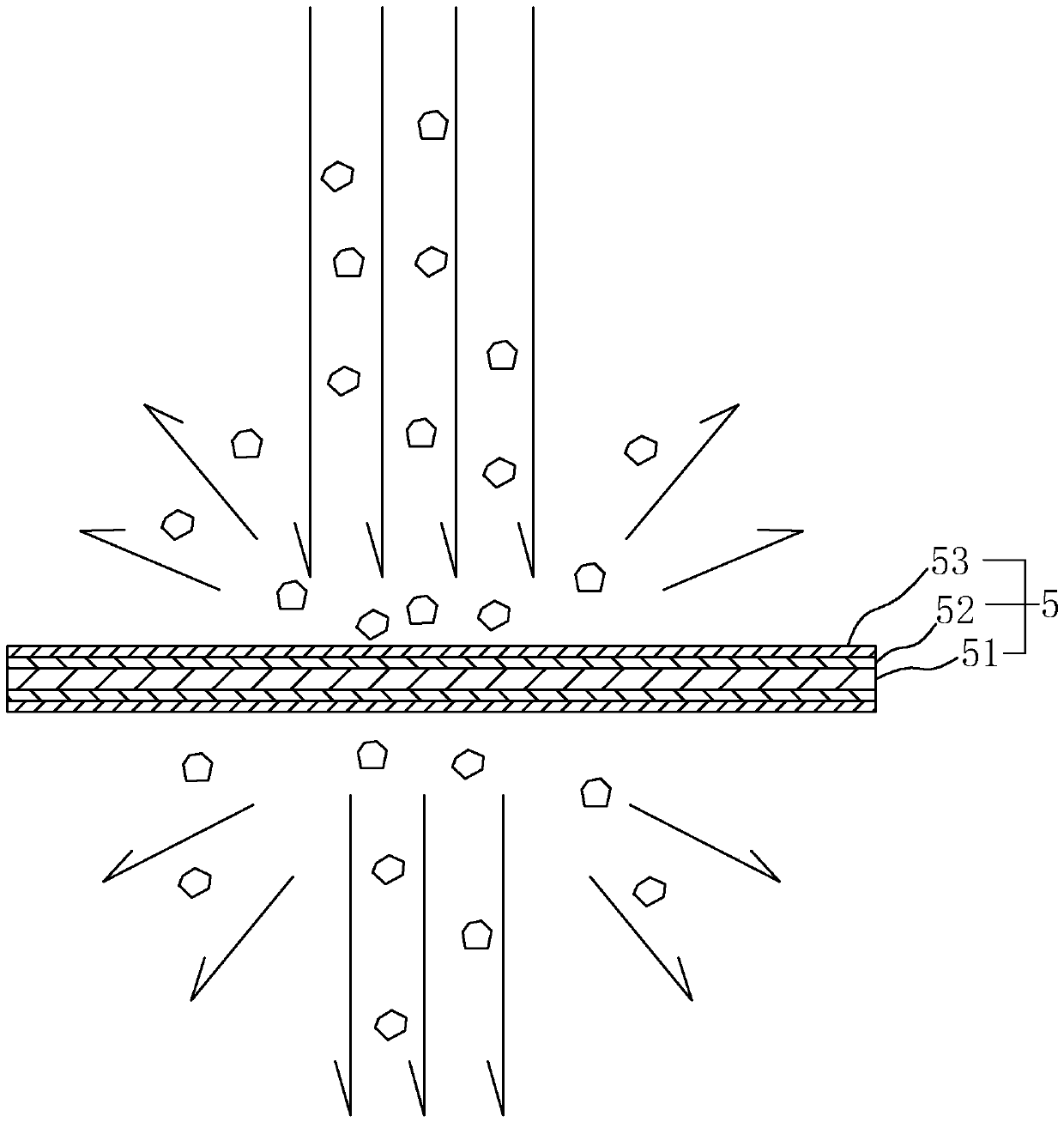

[0035] Wherein the positioning mechanism comprises a positioning plate 5 arranged on the workbench 4, the positioning plate 5 is used to be worn in the trouser legs of the jeans and i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap