Environment-friendly cement mixing device

A technology of mixing device and cement, applied in cement mixing device, clay preparation device, separation method, etc., can solve the problems of inability to treat dust, unable to recycle cement dust, etc., and achieve the effect of ensuring cleanliness, avoiding dust and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] see Figure 1 to Figure 9 , the present invention provides a technical solution:

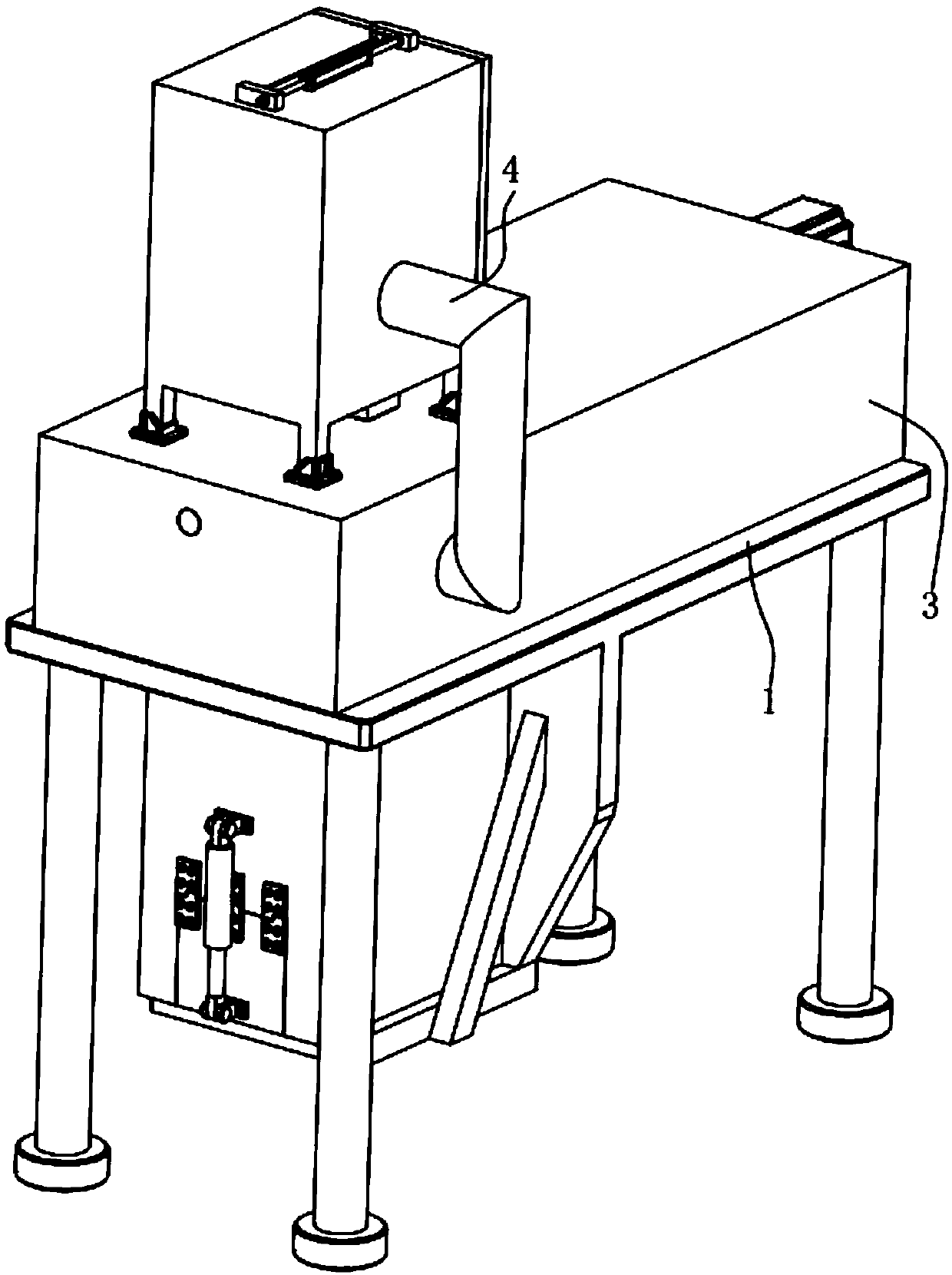

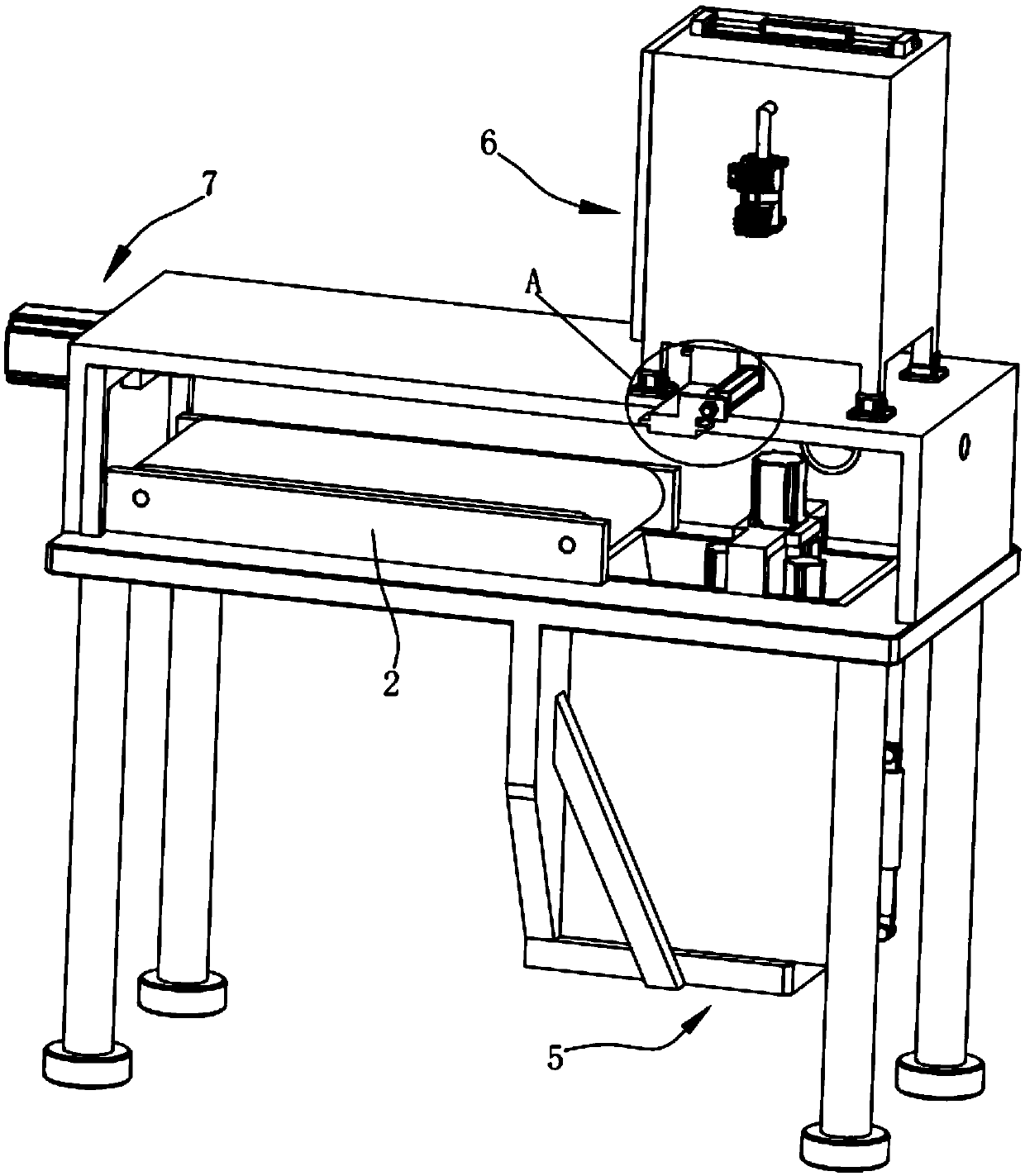

[0031] An environmentally friendly cement mixing device, including a frame 1, a conveyor belt 2, a sealing cover 3, a dust suction pipe 4, a mixing mechanism 5, a dust recovery mechanism 6 and a dust removal mechanism 7, wherein:

[0032] The conveyor belt 2 is installed on the top of the frame 1 by bolts, the sealing cover 3 is installed on the top of the frame 1 and encloses the frame 1 into a closed space, wherein the sealing cover 3 is provided with an opening groove 31, and the sealing cover 3 is a The ends of the sides are provided with openings for feeding;

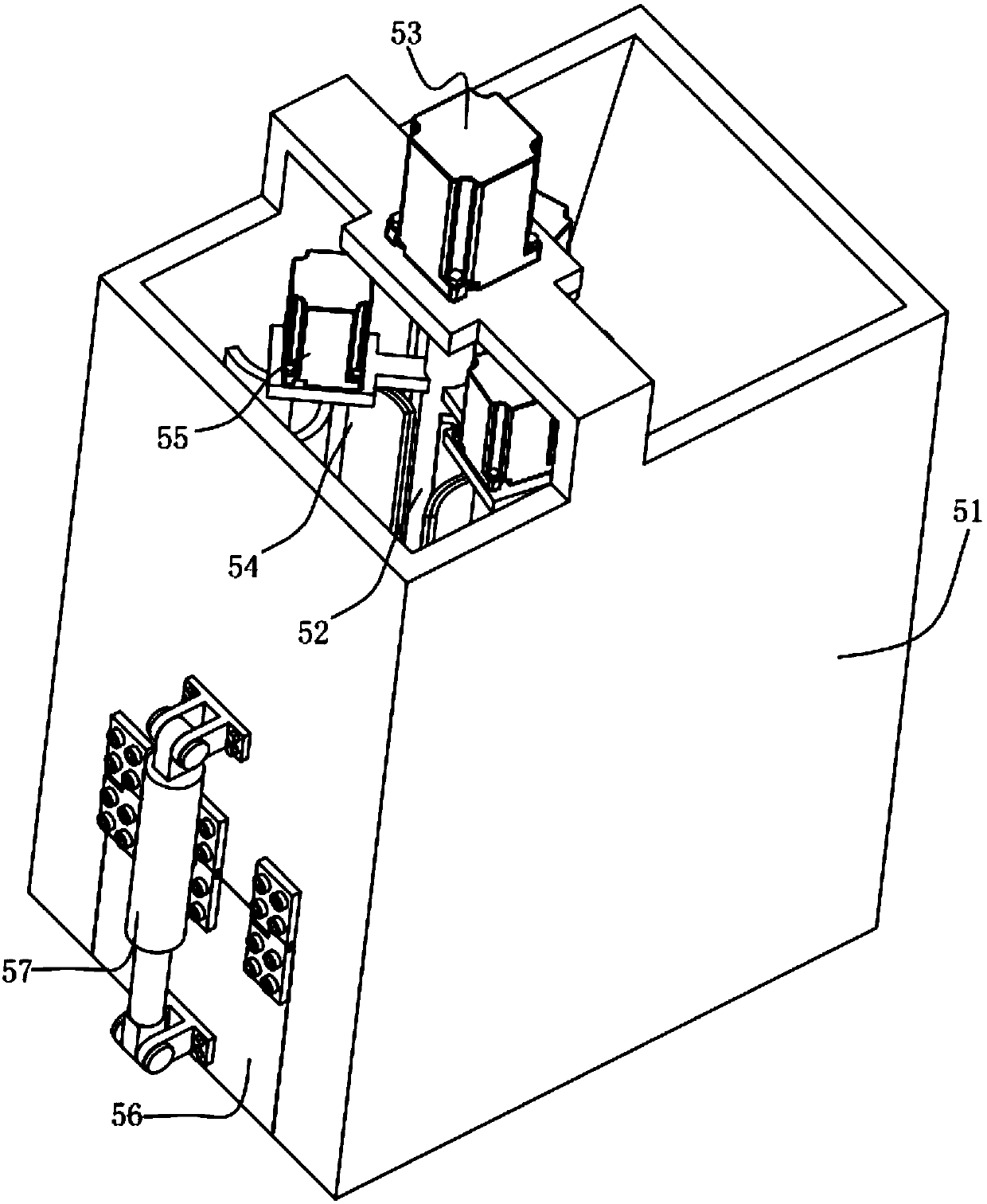

[0033] The stirring mechanism 5 includes a stirring box 51, a bracket-type rotating shaft 52, a reduction motor I53, an auger 54, a reduction motor II55, a baffle plate 56 and a hydraulic cylinder II57. The inside of the mixing box 51 is located below the end of one side of the conveyor belt 2 so as to be able to load the ra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap