Automatic packaging and labeling equipment for CTC cutter

A cutting tool and automatic technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that the cutting tool is easy to cut workers, affect the quality of the cutting tool, and low work efficiency, and achieve simple and reasonable structure, high degree of automation and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

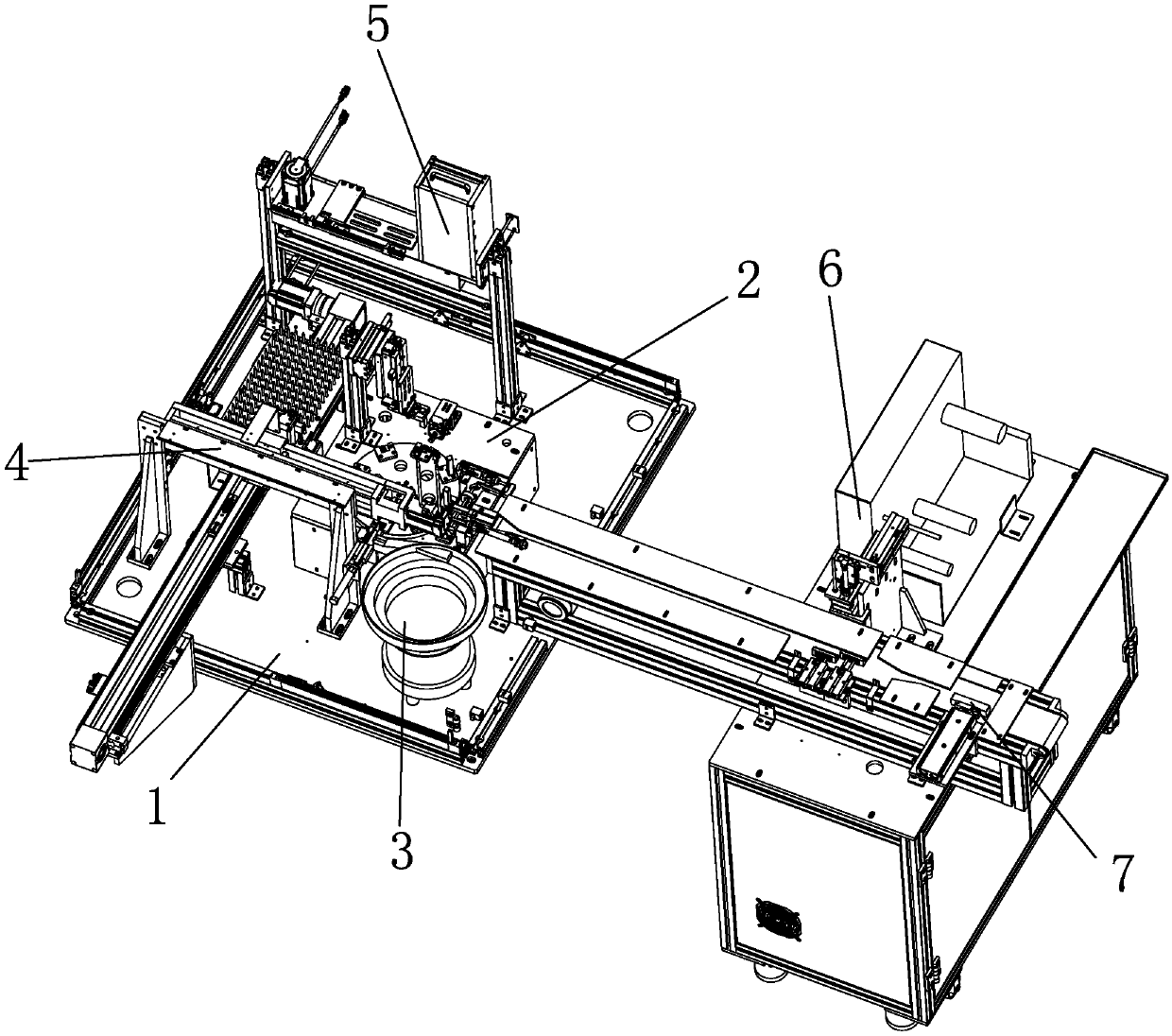

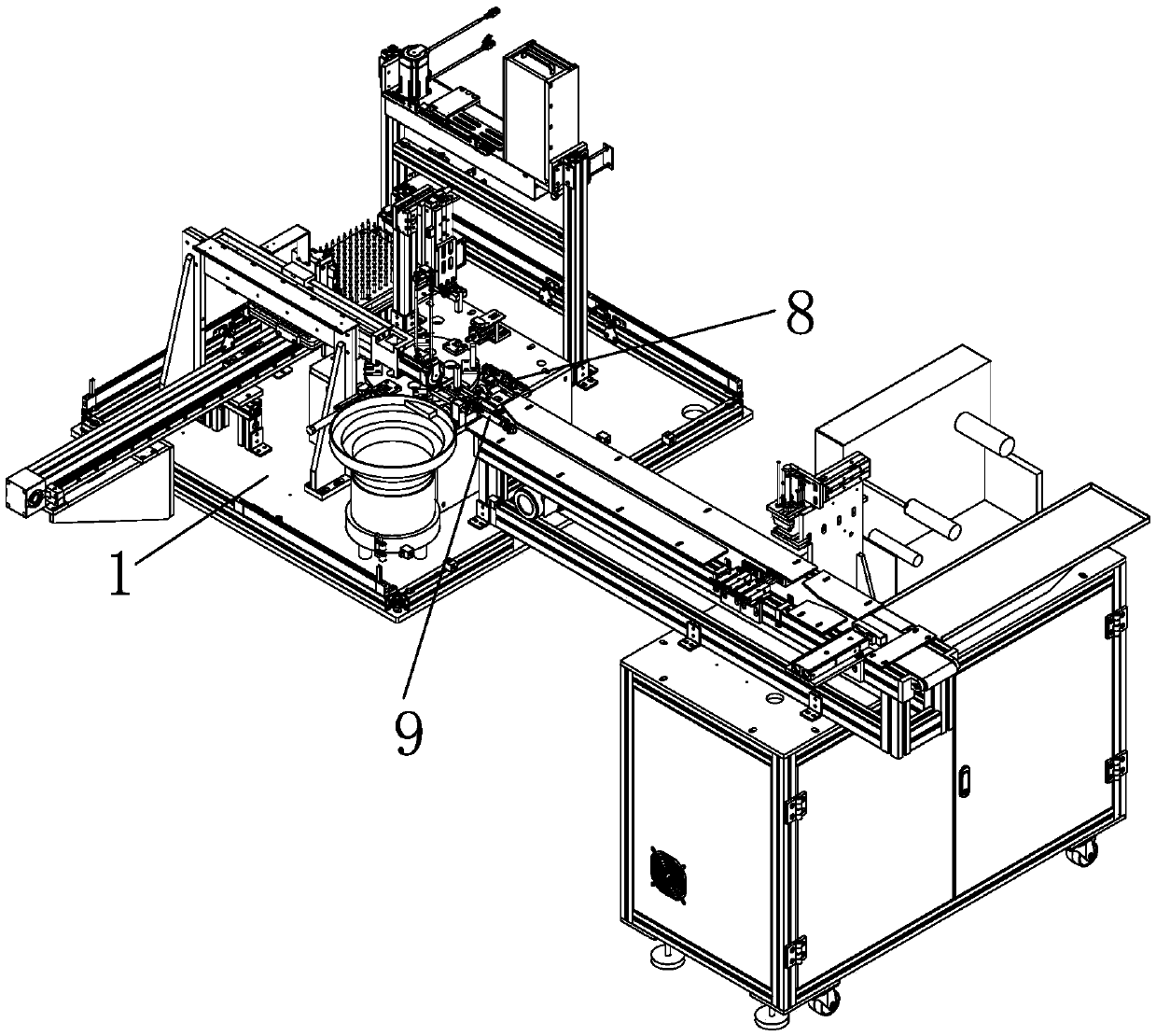

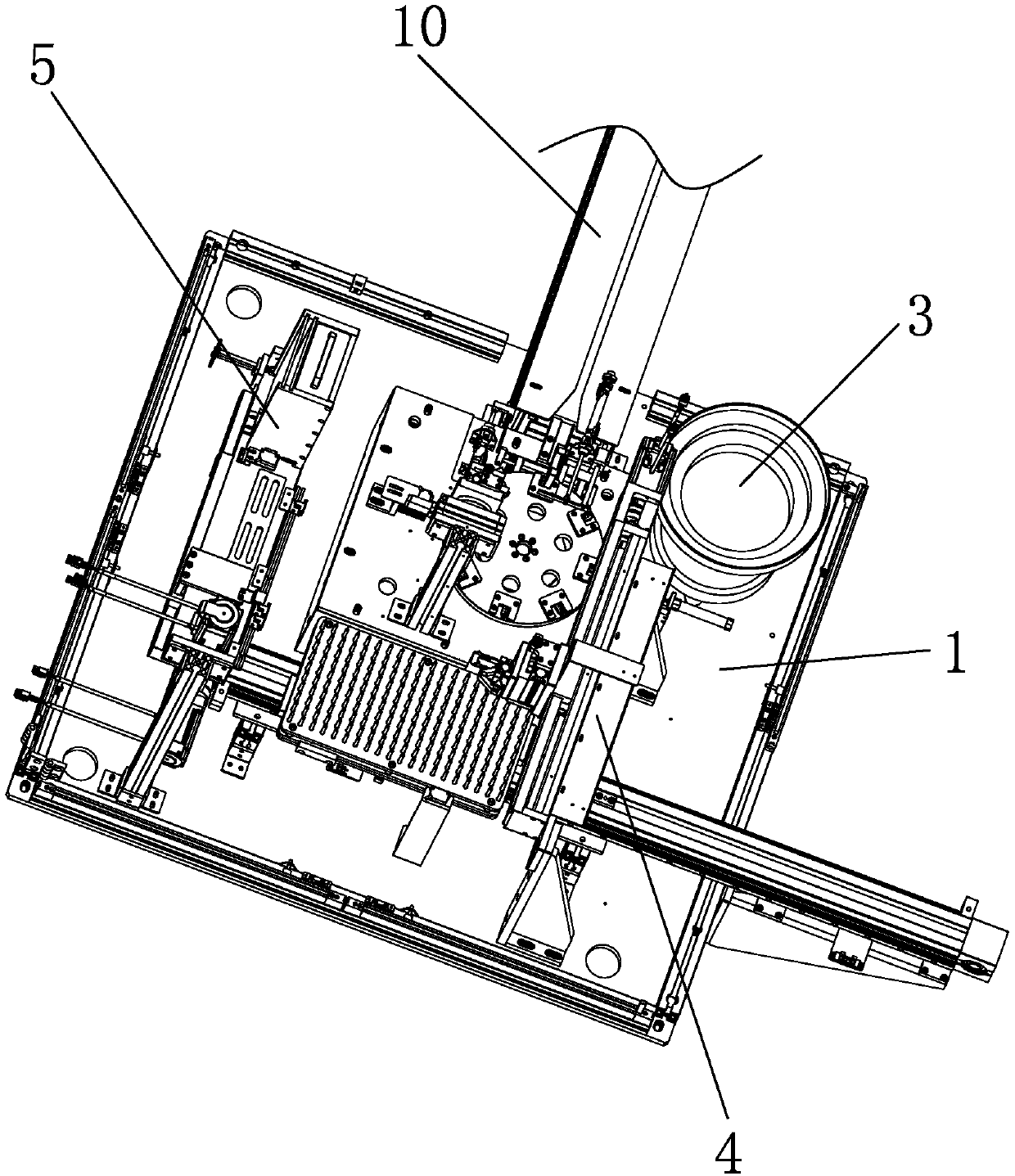

[0031] combine Figure 1 to Figure 4 , the invention discloses a CTC cutting tool automatic packaging and labeling equipment, including a machine 1, a rotary station 2 installed on the machine 1, a cover body feeding mechanism 3 arranged around the rotary station 2, and a tool top The feeding mechanism 4 and the shell feeding mechanism 5 , the conveyor belt 10 , the overturning assembly 8 and the pushing assembly 9 arranged on the rotary station 2 , and the marking mechanism 6 .

[0032] A turntable is arranged on the rotary station table 2, and a plurality of station seats are arranged on the turntable; preferably, 4-16 station seats are provided with positioning grooves. The cover feeding mechanism 3 places the cover feeding on the station seat. The tool feeding mechanism 4 places the tool feeding on the cover on the station seat. The shell feeding mechanism 5 places the shell on the cover on the station seat. One end of the conveyor belt 10 communicates with the rotary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com