Automatic film connection device

A membrane device and automatic technology, which is applied in transportation and packaging, winding strips, and thin material processing, etc., can solve the problems of unguaranteed product quality, low work efficiency, labor-intensive, etc., to reduce personnel participation, The effect of saving resource costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

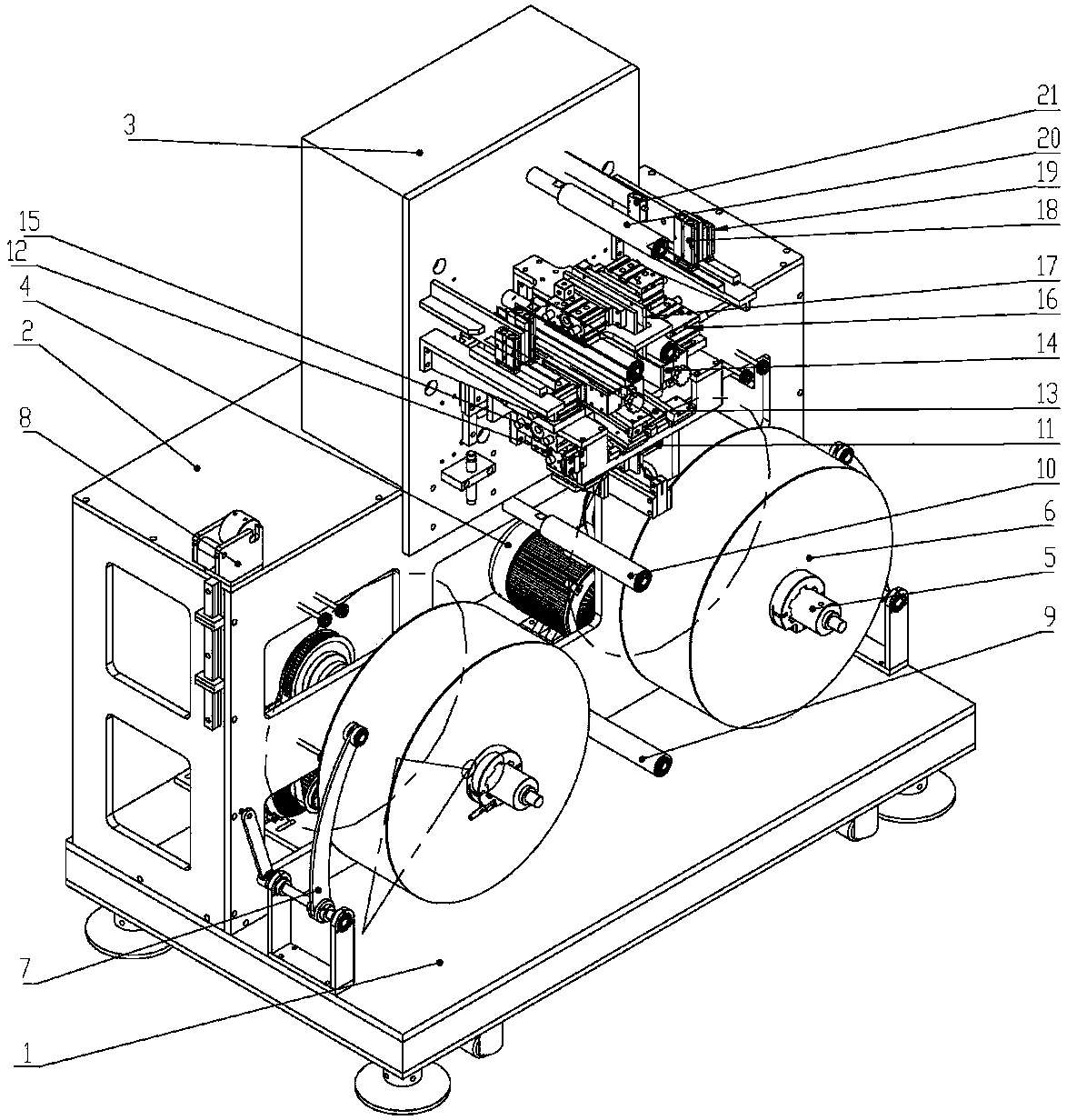

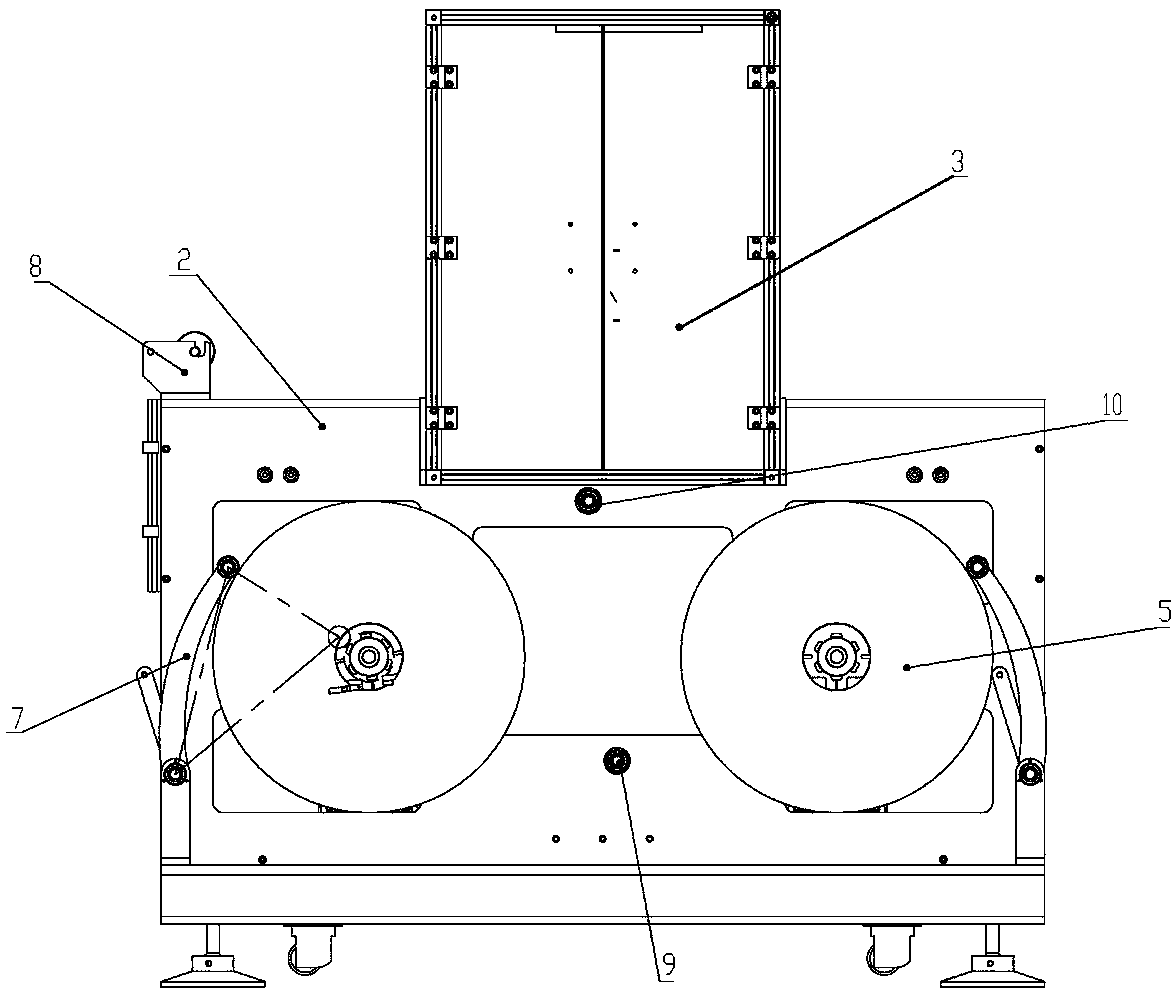

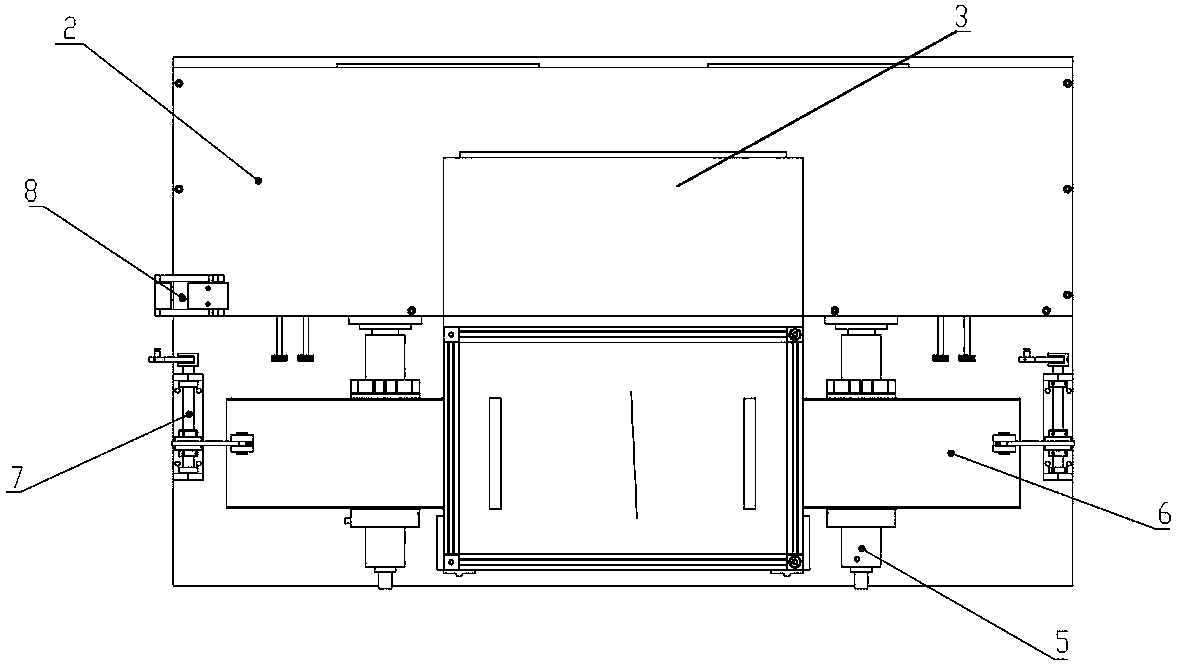

[0011] Depend on Figure 1-3 Given, the present invention comprises a base, a frame and a cylinder, the base 1 is equipped with a frame 2, and a roll diameter measuring instrument 7 is installed on both sides of the base 1 in front of the frame 2, and a right roll guide is connected in the middle of the frame 2 front. Roller 9 and left-hand roll excessive guide roller 10, the middle part of the front of the frame 2 is fixedly connected with the material-bearing air expansion shaft 5, the top platform of the frame 2 is installed with a tape cutter 8 and the film wallboard 3, and the inside of the frame 2 is installed There is a motor 4, and the motor 4 is connected with the material bearing air expansion shaft 5, and the lower part of the membrane wall panel 3 is equipped with a lower left clamping cylinder 12, a lower ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com