Prefabricated anti-seismic beam and beam node

A technology of anti-seismic beams and joints, applied in the direction of anti-seismic, joists, girders, etc., can solve the problems of reduced anti-seismic performance, poor connection and overall stability, and achieve the effect of increasing strength, improving overall resistance, and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

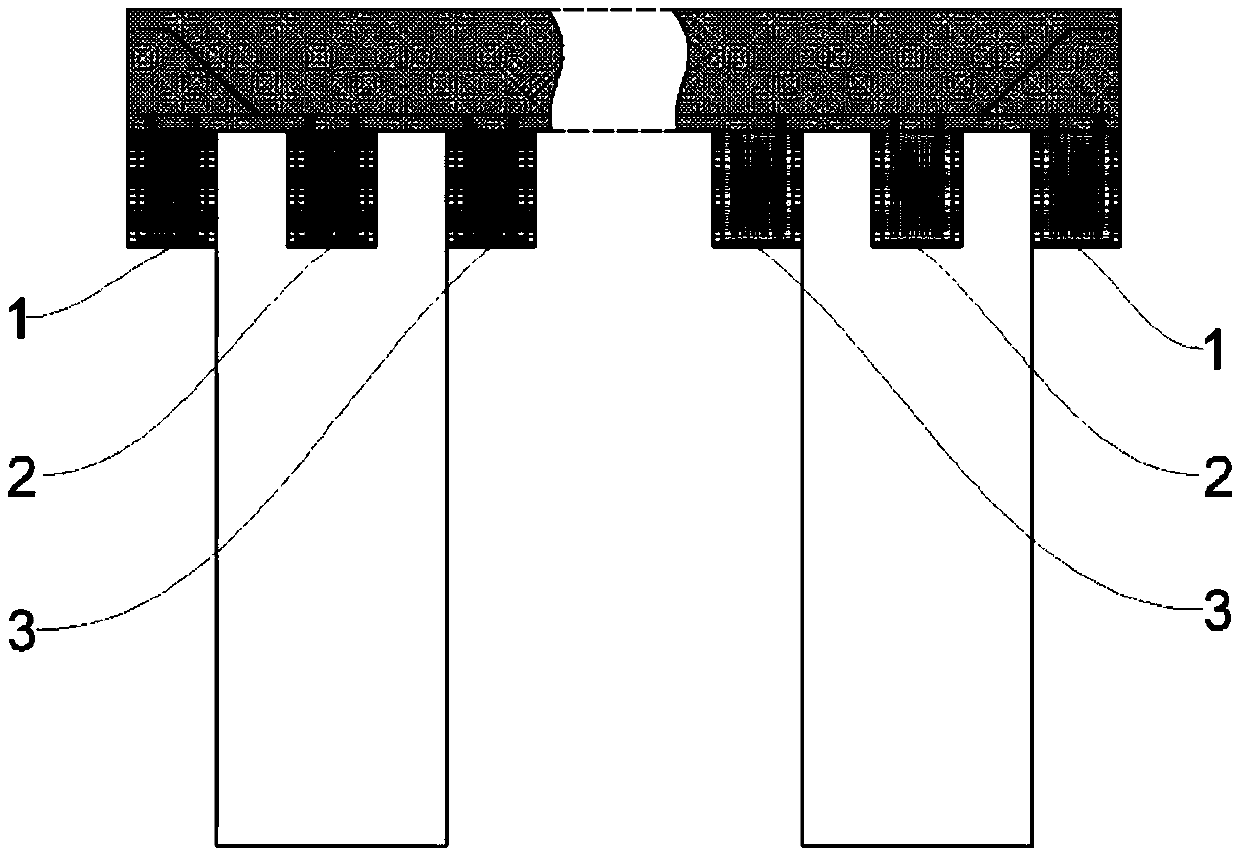

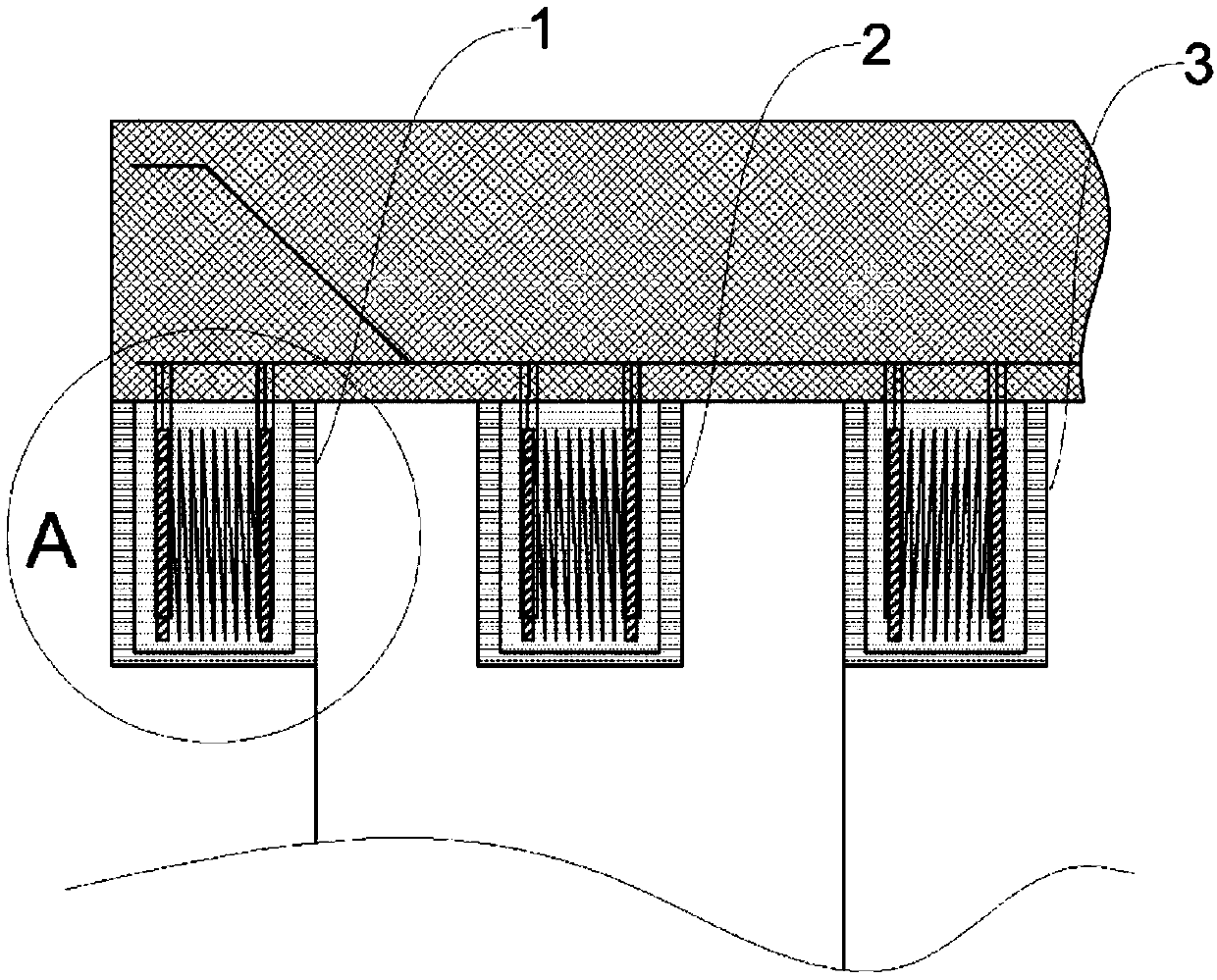

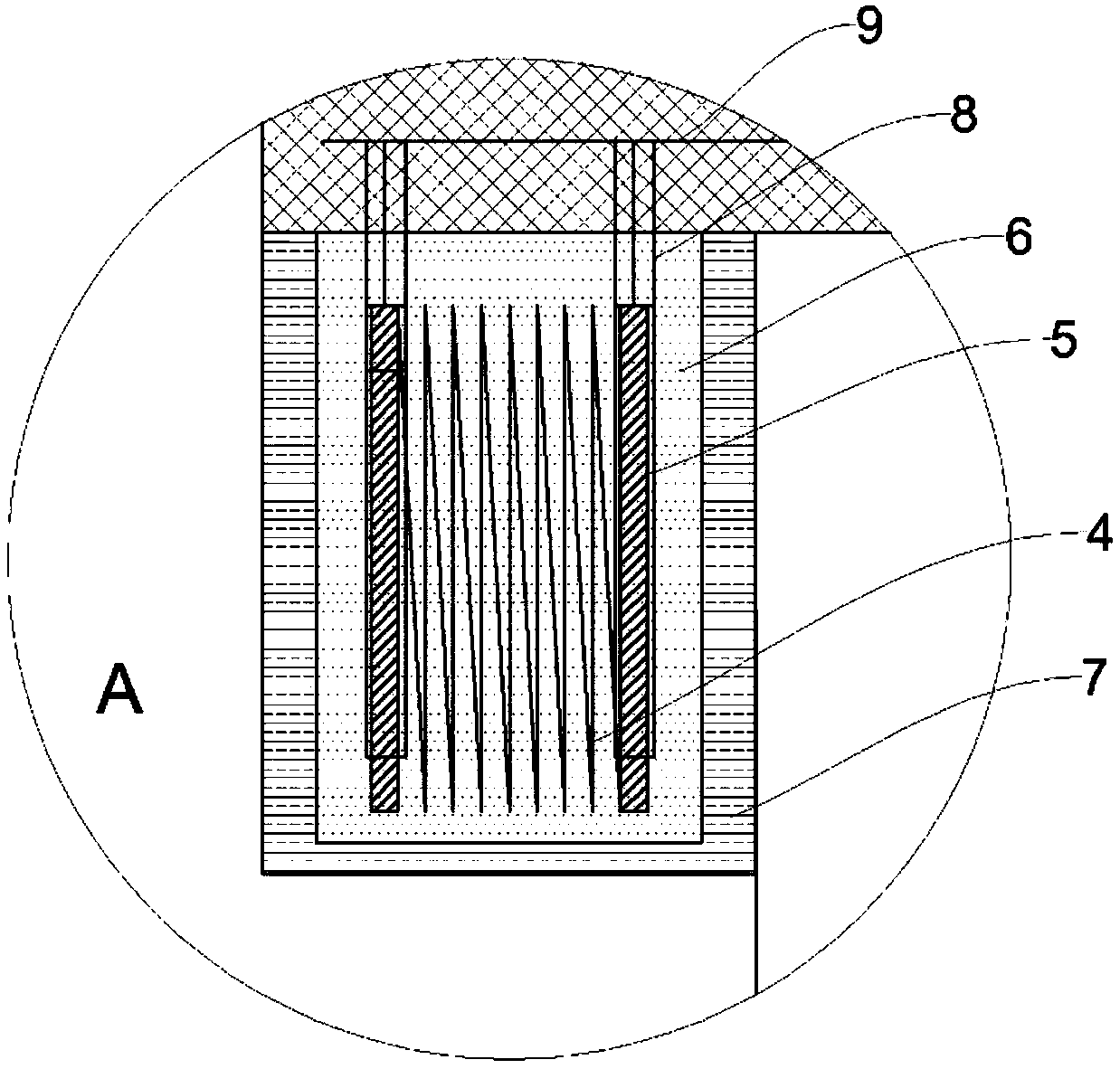

[0032] Such as figure 1 , figure 2 , image 3 As shown, a prefabricated anti-seismic beam and beam joints provided by the present invention have protruding outer wings 1, middle wings 2, and inner wings 3 on the lower sides of both ends of the beam; the middle wings 2 are inserted into the connecting columns, The outer wing 1 and the inner wing 3 are attached to the two sides of the connecting column respectively; the outer wing 1, the middle wing 2, and the inner wing 3 are provided with a compression spring 4 perpendicular to the connecting column, and the compression spring 4 is connected with a Buffer board 5, said buffer board 5 is fixedly connected with beam main reinforcement 9 through stirrups 8; said outer wing 1, middle wing 2, and inner wing 3 are filled with graphene foam 6.

[0033] During an earthquake, the damage to buildings caused by seismic waves is mainly reflected in the shear waves, so the beam-column joints are the main damage points, especially on pre...

Embodiment 2

[0043] Such as Figure 4 As shown, the present embodiment makes the following changes on the basis of embodiment 1, the outer surface of the outer wing 1 is set as an arc surface or a conical surface (arc surface in the figure). From the structural change of the present invention, it can be known that the outer wing 1 will protrude to a certain thickness of the outer wall according to the conventional arrangement. The resulting accumulation of dust at the end of the beam, especially the long-term accumulation of rain and snow in rainy and snowy weather, will have a certain erosive effect on the interior. In addition, strong winds are often accompanied by earthquakes, and the design of the curved surface can effectively reduce the lateral force of strong winds on beam-column joints, thereby reducing the damage caused by earthquakes.

Embodiment 3

[0045] Such as Figure 5 As shown, in this embodiment, on the basis of Embodiment 1, damping wings (outer wing 1, middle wing 2, and inner wing 3) are arranged on the upper and lower sides of the two ends of the beam, and the beam and the upper and lower connecting columns on this basis The integrity is better, and the anti-seismic effect is better.

[0046] Such as Figure 6 Shown is the further optimization of this embodiment, wherein the arc surface of the upper and lower outer wings 1 and the outer end surface of the beam are designed as a large arc surface as a whole, which improves the integrity of the beam and simplifies the overall structure, reduces the prefabrication process, and has a significant The advantages.

[0047] To sum up, the prefabricated beam provided by the present invention can achieve significant seismic effect only by changing the structural design of both ends of the beam and the nodes. Mass production, in line with the principle of anti-seismic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com