Vacuum system

A vacuum system and vacuum cover technology, applied in the field of vacuum systems, can solve problems that affect the accuracy and reliability of vacuum pump performance research, difficult gas supply, and actual value deviation, etc., to avoid low detection accuracy, accurately measure flow, and improve detection The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

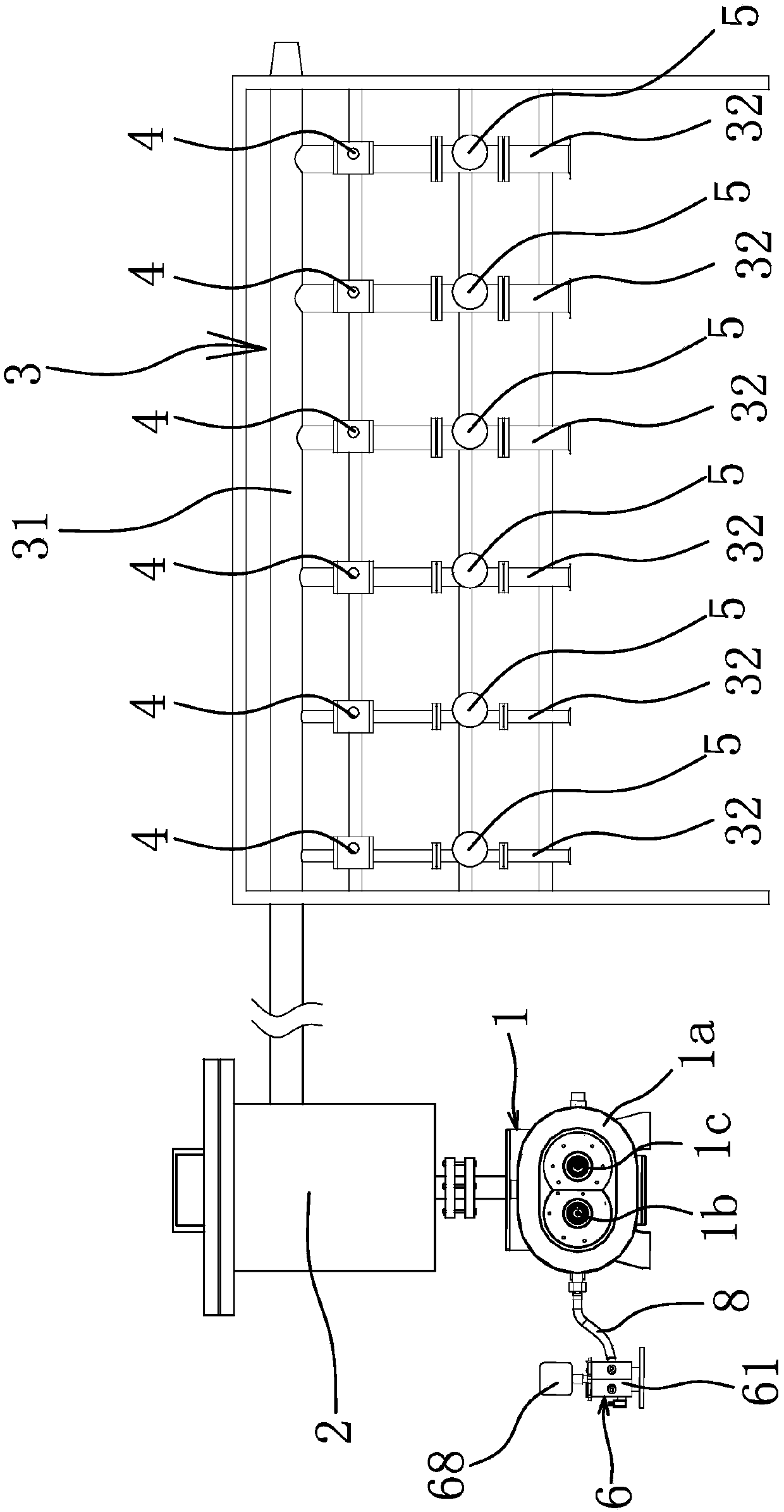

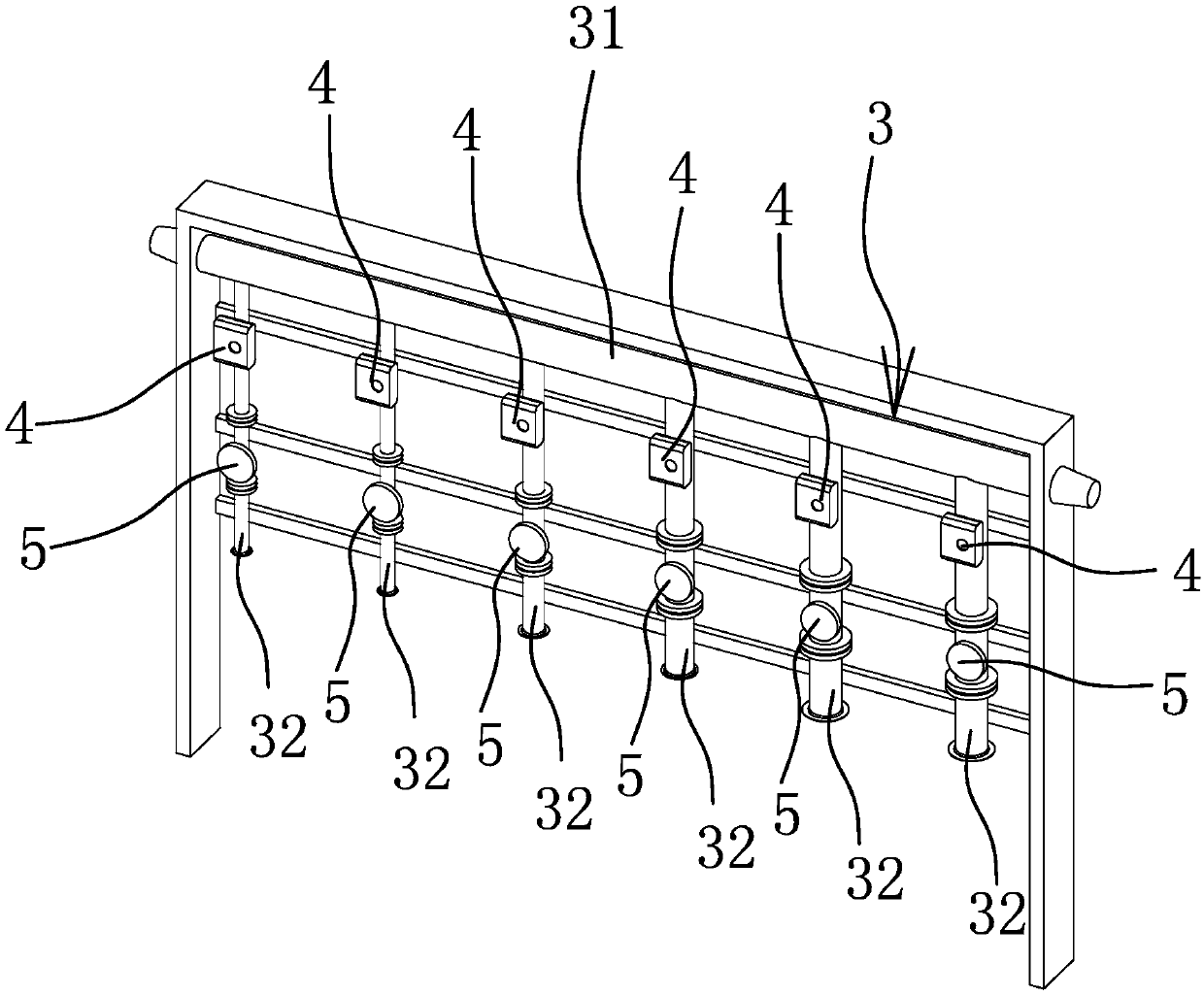

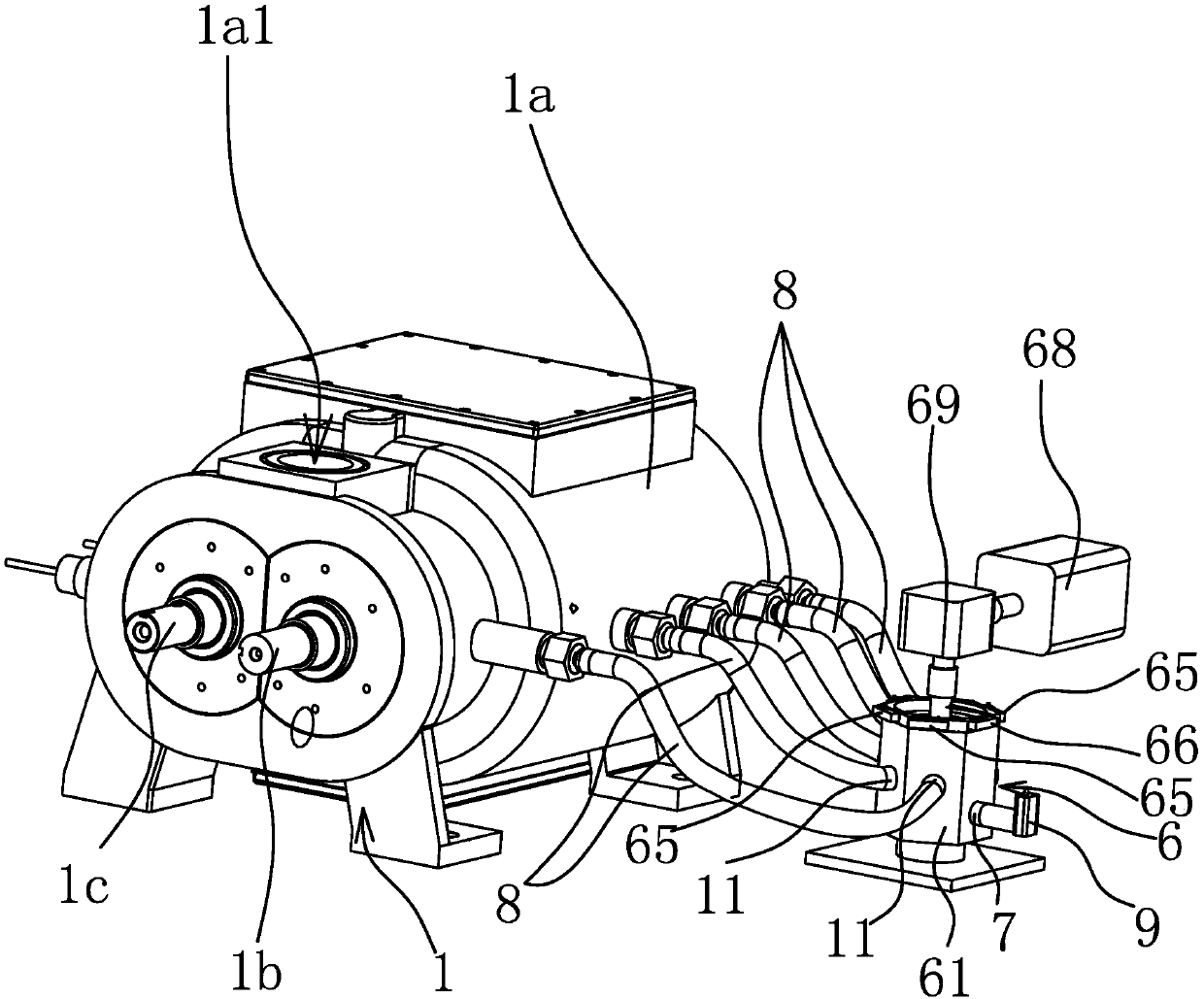

[0033] Such as figure 1 with figure 2 As shown, the vacuum system includes a screw vacuum pump 1 , a vacuum cover 2 connected to the air inlet 1a1 of the screw vacuum pump 1 , and an air supply pipeline 3 for supplying air to the vacuum cover 2 . The air supply pipeline 3 includes a horizontally arranged air supply main pipe 31 and six air supply branch pipes 32 connected with the air supply main pipe 31. The air supply main pipe 31 is connected with the vacuum cover 2, and each air supply branch pipe 32 is provided with a flow rate meter 5 and a flow control valve 4, the vacuum system also includes a controller for receiving the flow signal sent by the flow meter 5 and outputting a control signal to control the opening of the flow control valve 4, the controller is not shown in the figure, each flow Meter 5 and each flow control valve 4 are all connected with the controller. The controller is preferably a single-chip microcomputer, and the flowmeter 5 is preferably a remot...

Embodiment 2

[0045] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the number of gas supply branch pipes 32 is five, and the diameters of the five air supply branch pipes 32 are all different.

Embodiment 3

[0047] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the number of gas supply branch pipes 32 is 7, and the diameters of the 7 gas supply branch pipes 32 are all different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com