Speed reducing device of valve intelligent executer

A reduction device and actuator technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of low transmission ratio, small driving torque, and large working noise, so as to reduce operation risk, Large output torque and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

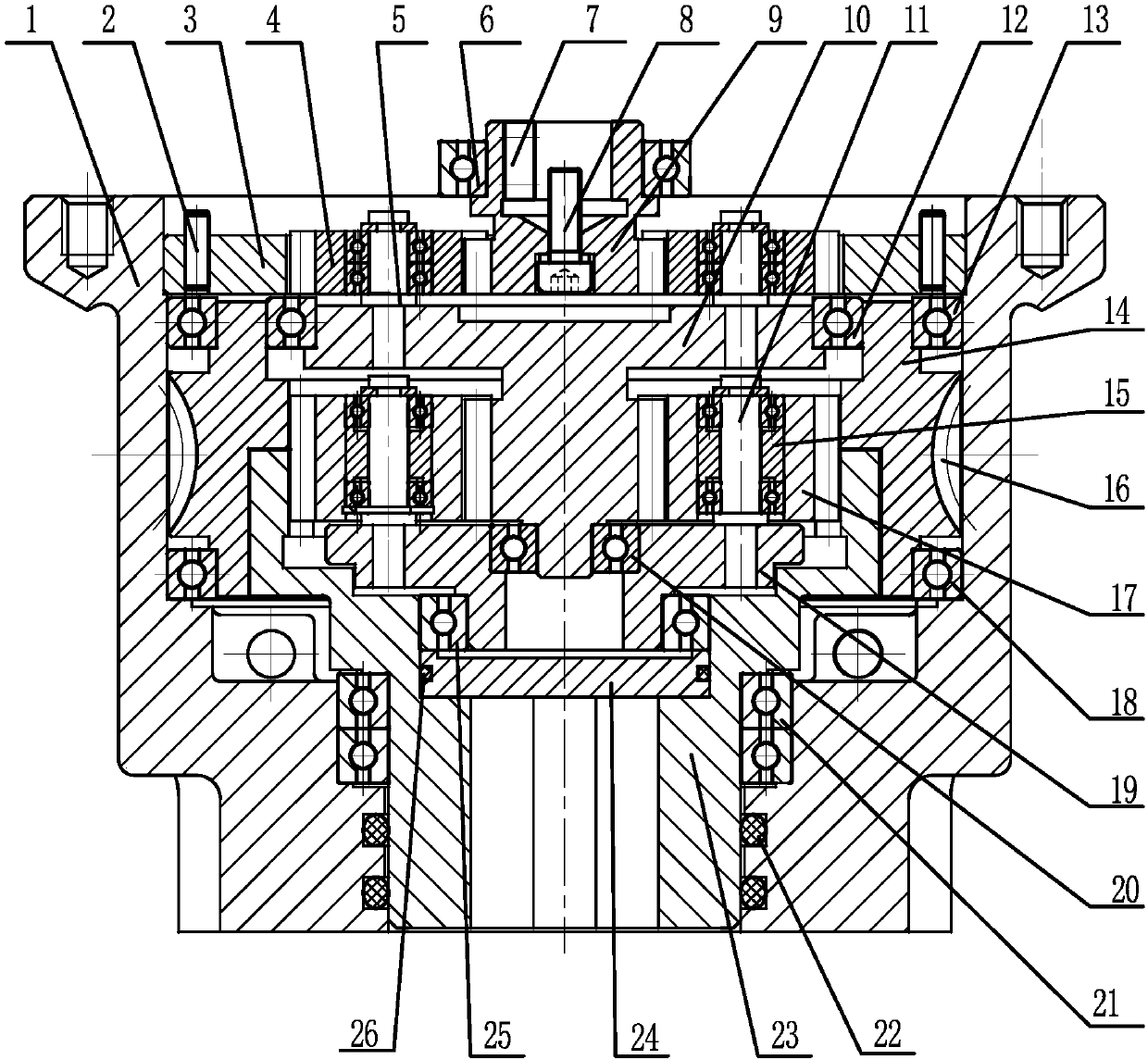

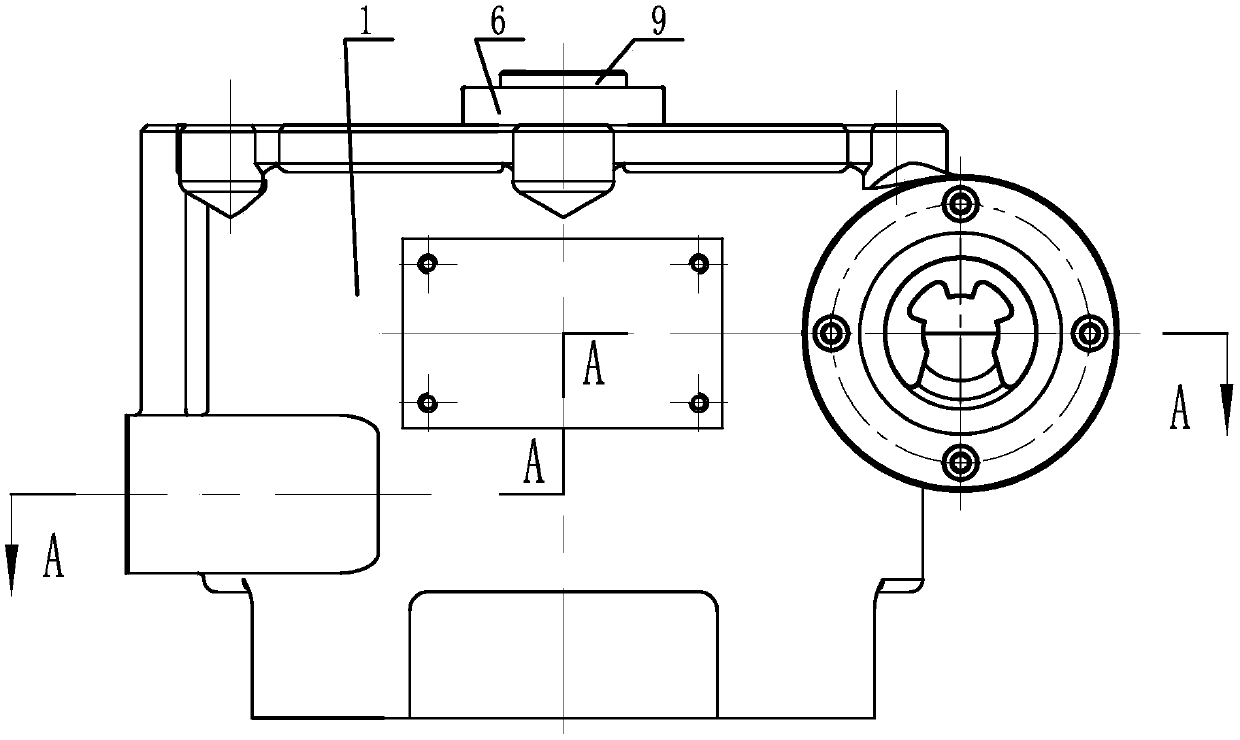

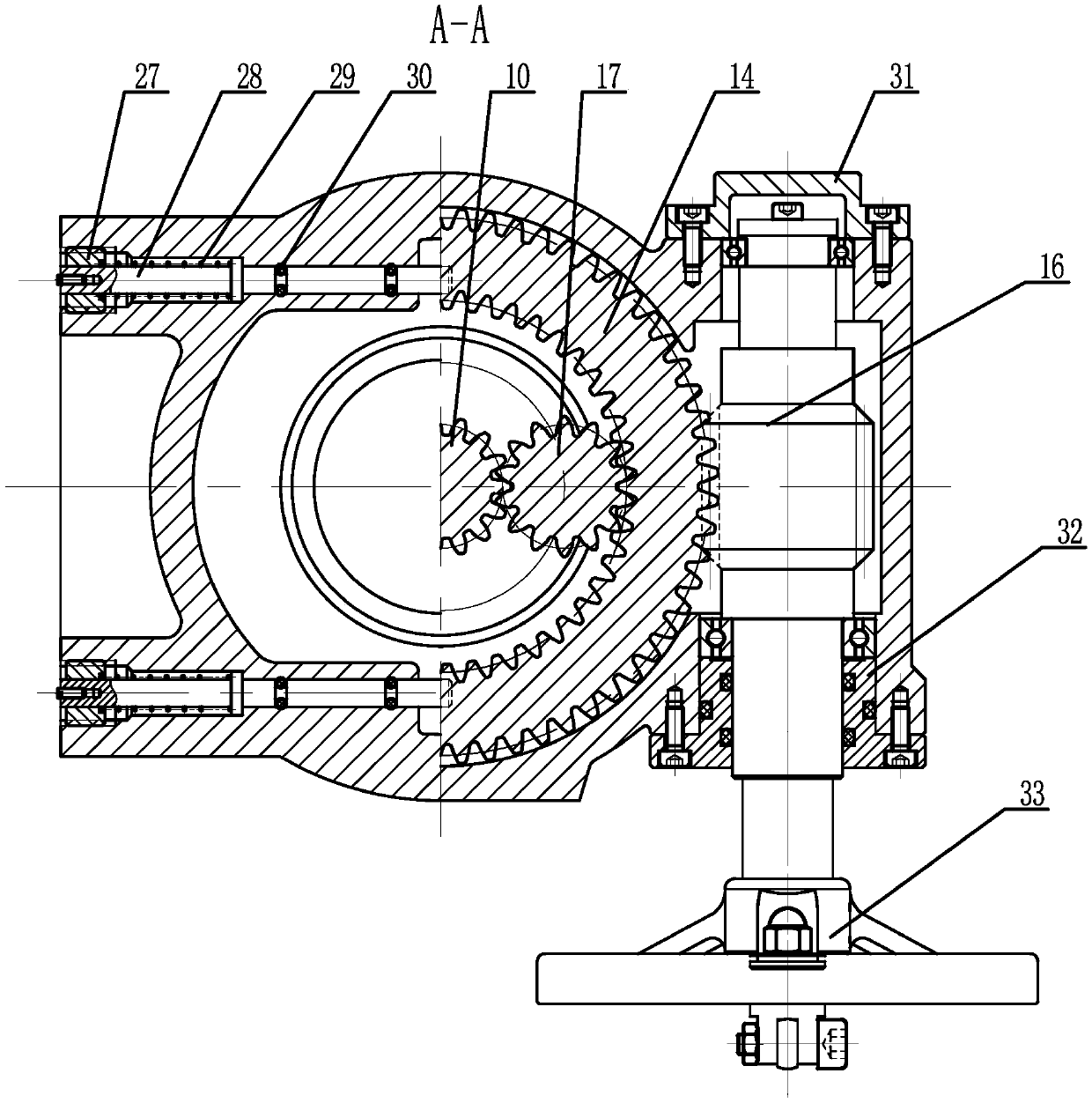

[0017] See Figures 1 to 3 As shown, the deceleration device of the valve intelligent actuator of the present invention includes a box body 1, a two-stage planetary gear reduction mechanism arranged in the box body 1, and a worm gear mechanism for manual operation. The box body 1 of the present invention has a cavity for accommodating the secondary planetary gear reduction mechanism and the worm gear mechanism, and the end face of the box body 1 is connected with the end face of the motor body, which can be connected by fasteners. The present invention is convenient for connecting with the motor body. The first-stage ring gear 3 is provided with a positioning pin 2, which can facilitate the positioning, installation and removal of the motor and the reduction gear.

[0018] See figure 1 As shown, the secondary planetary reduction mechanism of the present invention includes a sun gear 9 with a first external tooth, at least two primary planetary gears 4, a primary ring gear 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com