Steel slag hot stewing exhaust steam cooling tower

A technology of cooling tower and thermal braising, which is applied in the field of iron and steel metallurgy, can solve problems such as pollution and environmental impact, and achieve the effect of uniform steam distribution, reduced impact, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

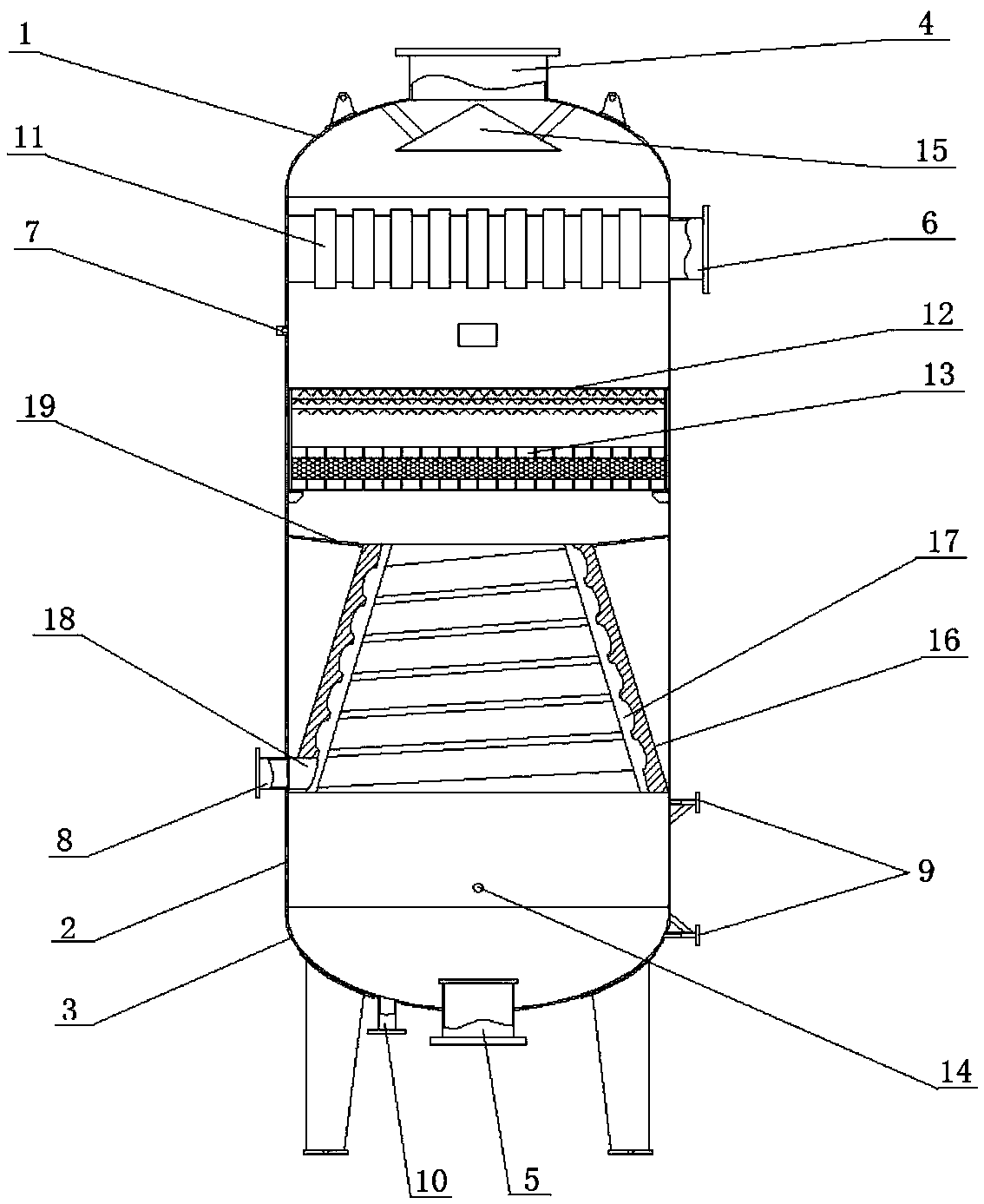

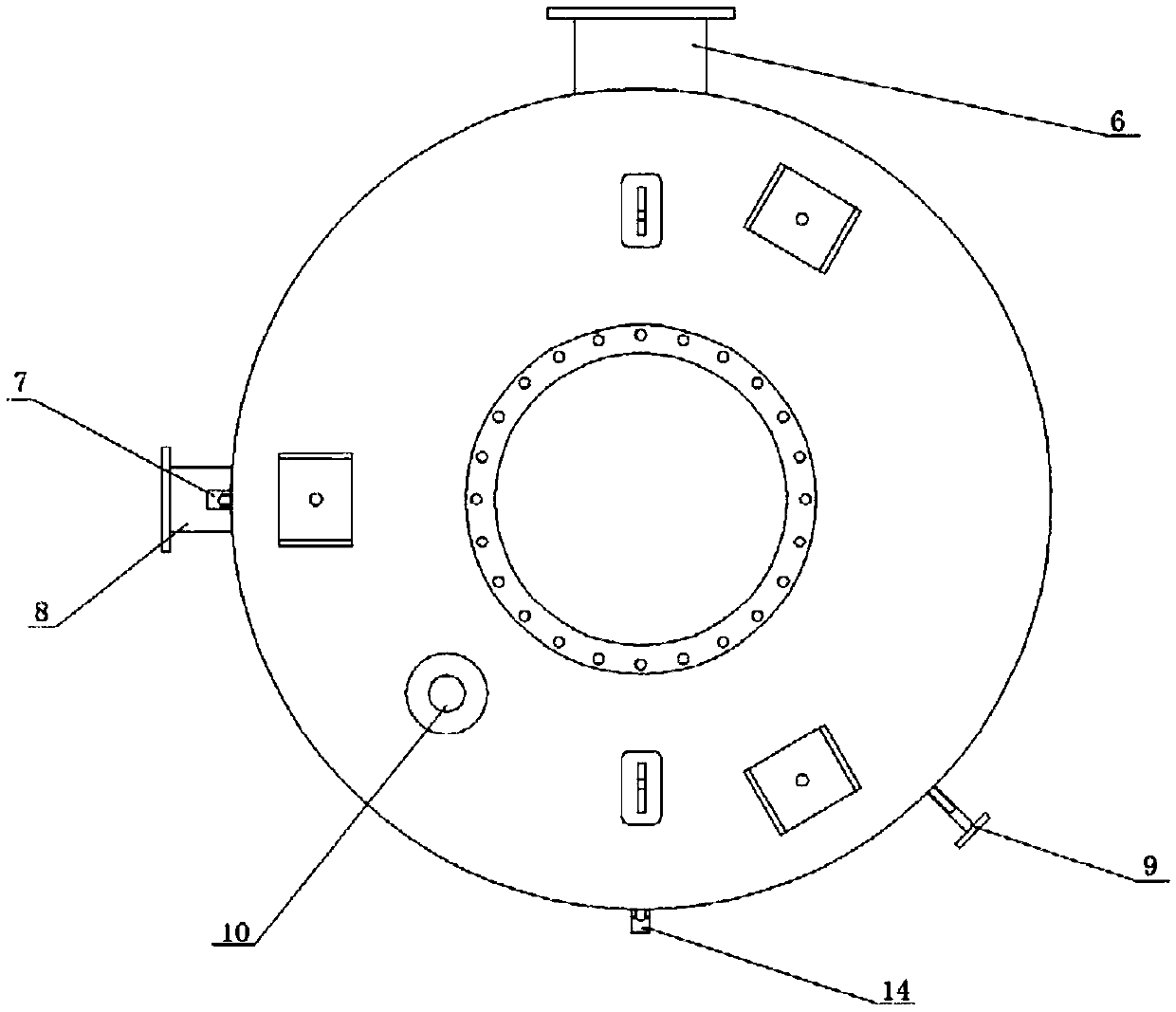

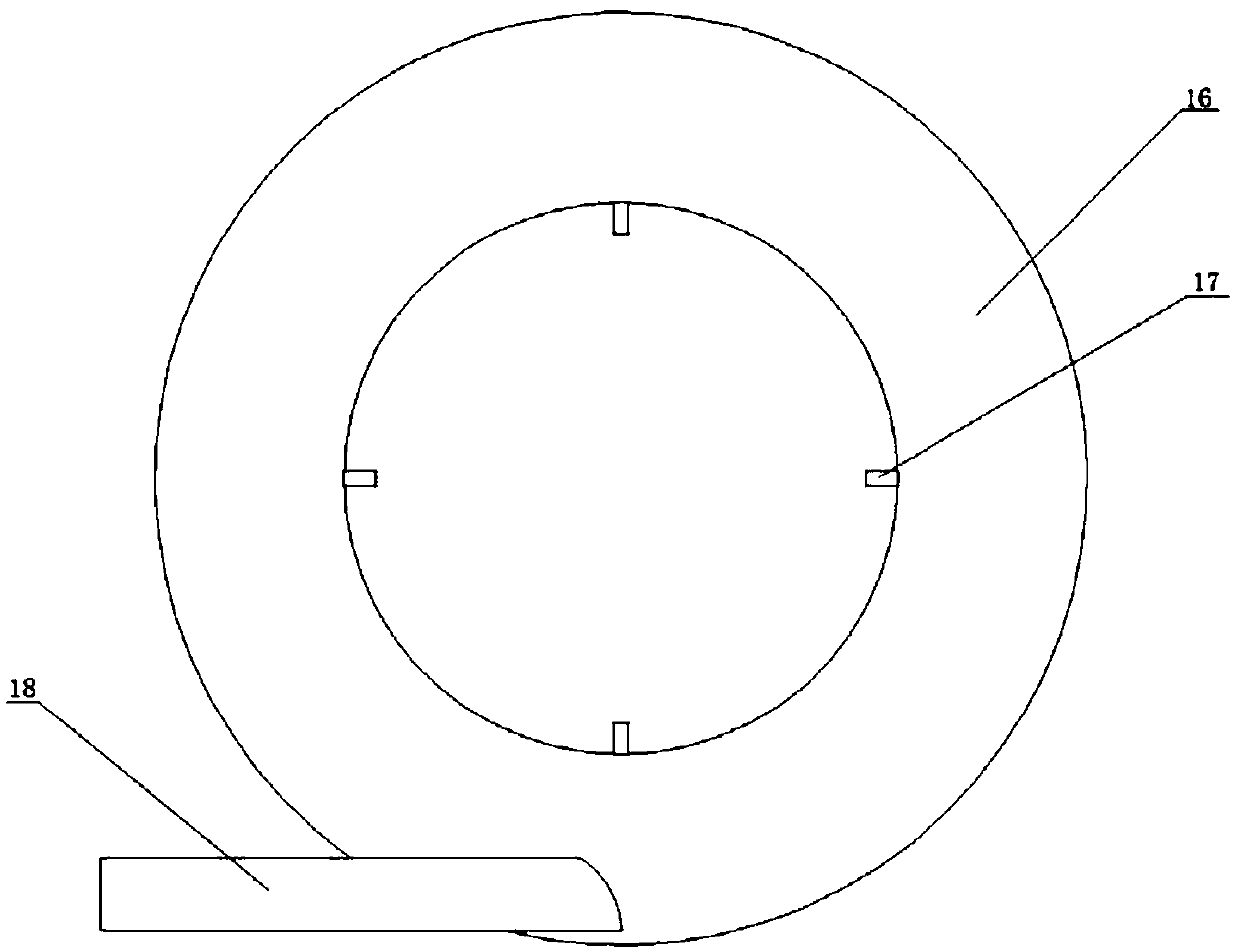

[0023] The specific technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0024] In the figure, 1 is the upper head; 2 is the tower shell; 3 is the lower head; 4 is the exhaust port; 5 is the drain port; 6 is the cooling water inlet; 7 is the pressure gauge interface; 8 is the steam inlet; 9 is Liquid level interface; 10 is the sewage outlet; 11 is the film spinner; 12 is the heat exchange layer; 13 is the dust removal packing layer; 14 is the thermometer interface; 15 is the conical top cap; 16 is the conical shell; Steam pipeline; 19 is an annular baffle.

[0025] A steel slag thermal exhaust steam cooling tower comprises a cooling tower main body, in which a spray assembly, a heat exchange dust removal assembly and a dust removal steam distributor are sequentially arranged from top to bottom. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap