Fault detection method and system of battery pack

A fault detection and battery pack technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., it can solve the problem of limited number of temperature acquisition ports, inability to collect cell temperature data, and inability to accurately reflect the status of battery cells and other problems to achieve the effect of avoiding short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

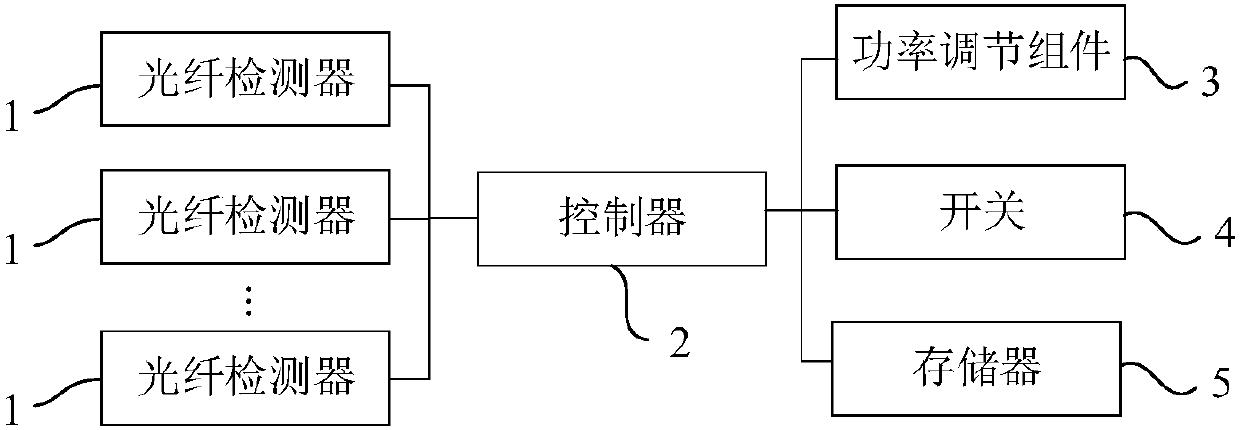

[0051] The fault detection system of the battery pack of this embodiment is used to realize the fault detection of the battery pack, wherein the battery pack includes at least one battery cell. Such as figure 1 As shown, the fault detection system of this embodiment includes: an optical fiber detector 1 and a controller 2. The optical fiber detector 1 is arranged on the outer surface of each cell, and is used to detect the temperature value of the cell and send the temperature value to the controller. The controller 2 determines whether the temperature value is within the preset temperature range, and generates an alarm message when the determination is yes.

[0052] It should be noted that different types of batteries have different battery usage scenarios and different requirements for fault judgment. Therefore, the preset temperature range needs to be set according to the battery type and usage scenario.

[0053] In this embodiment, the light detector includes an optical fiber,...

Embodiment 2

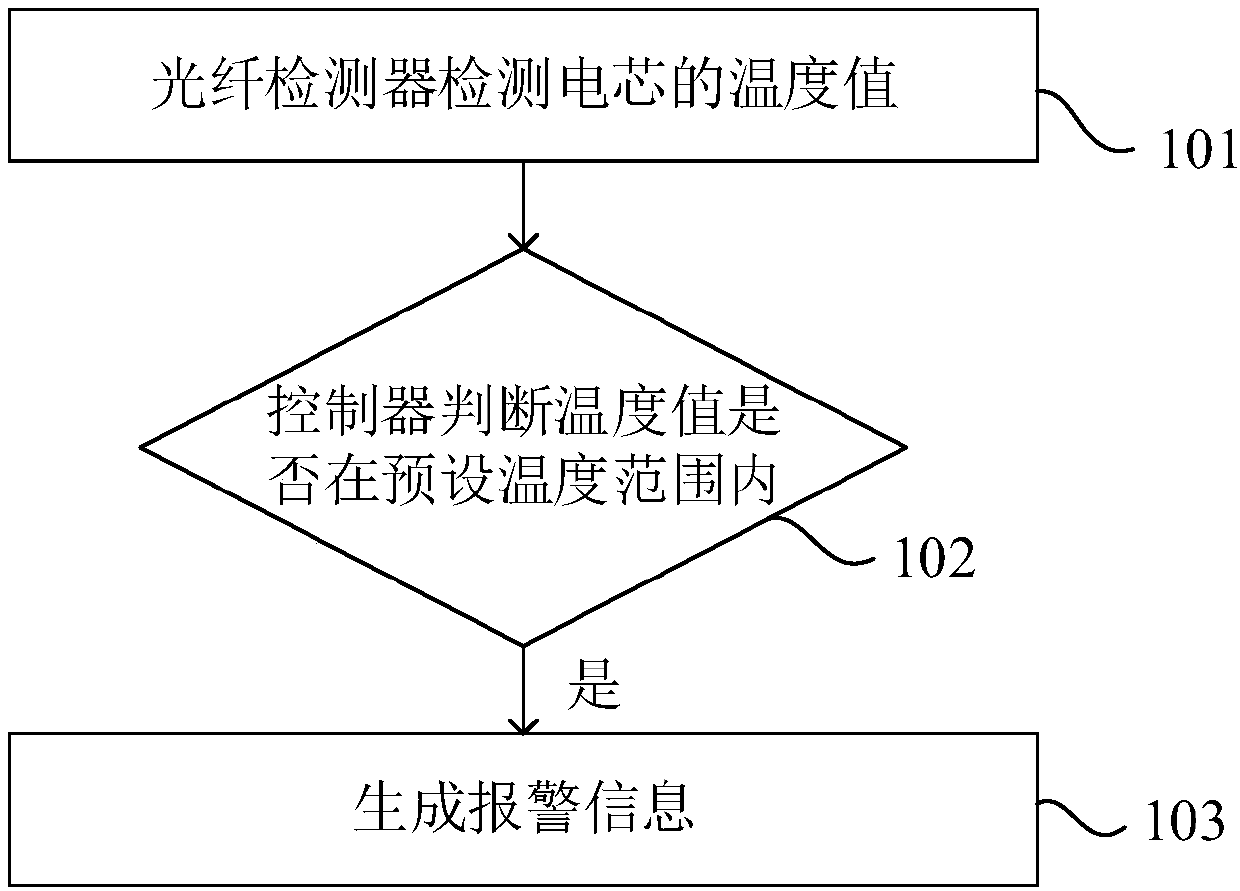

[0062] The present invention also provides a fault detection method for a battery pack, which is implemented using the fault detection system of implementation 1, such as figure 2 As shown, the fault detection method includes the following steps:

[0063] Step 101: The optical fiber detector detects the temperature value of the battery core.

[0064] Step 102: The controller determines whether the temperature value is within a preset temperature range. If the judgment is no, then no action; if the judgment is yes, then step 103 is executed.

[0065] Step 103: Generate alarm information.

[0066] Wherein, the temperature value includes a maximum temperature and / or a minimum temperature and / or a temperature difference within a preset time period. Among them, the temperature difference is the difference between the maximum temperature and the minimum temperature.

[0067] In this embodiment, the optical fiber is arranged on each battery cell to realize the temperature data collection of...

Embodiment 3

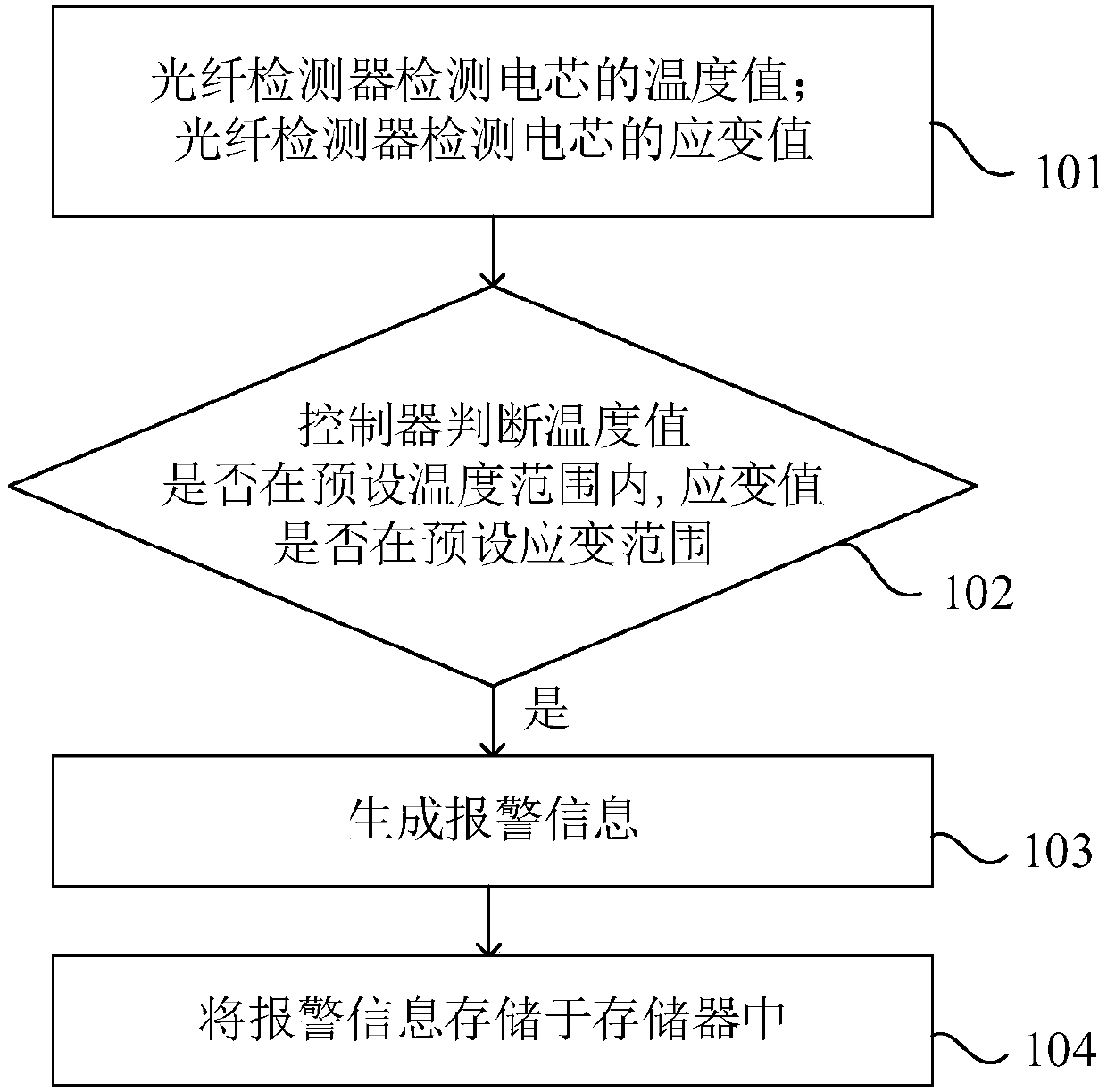

[0069] Example 3 is basically the same as Example 2, such as image 3 As shown, in this embodiment, step 101 further includes:

[0070] The optical fiber detector detects the strain value of the cell.

[0071] Step 102 also includes:

[0072] The controller judges whether the strain value is within the preset strain range.

[0073] In this embodiment, after step 103, the method further includes:

[0074] Step 104: Store the alarm information in the memory.

[0075] In this embodiment, not only the temperature of the battery pack is detected, but also the deformation detection of the battery pack is realized, that is, the deformation and strain of the box of the battery pack when a variety of extreme abnormal accidents such as a vehicle collision occurs. Detect to avoid short circuit of internal high voltage battery caused by deformation of battery box. In this embodiment, the failure of the battery pack is predicted simultaneously by the strain value and the temperature, which can furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com