An experimental device for simulating the dynamic change of material level in blast furnace throat material descending process

A blast furnace throat, dynamic change technology, applied in the direction of measuring devices, teaching models, machine/structural component testing, etc., can solve the problems of unbalanced center and edge blanking, difficult actual measurement and research, etc., to achieve convenient and fast observation and measurement , Small experimental workload and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

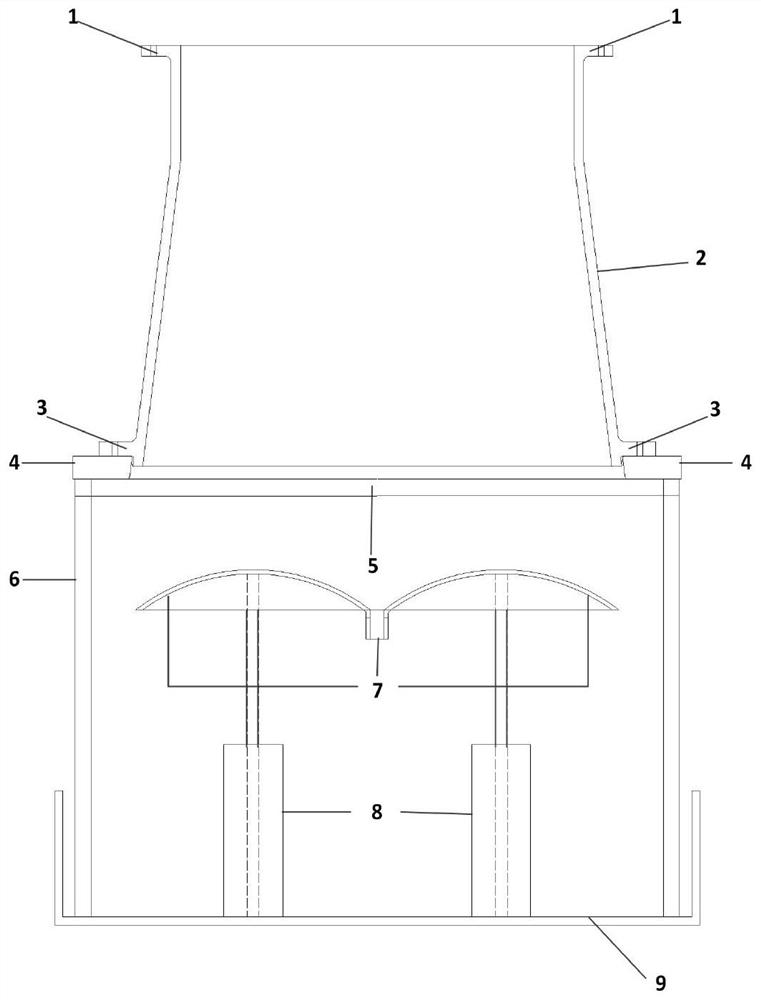

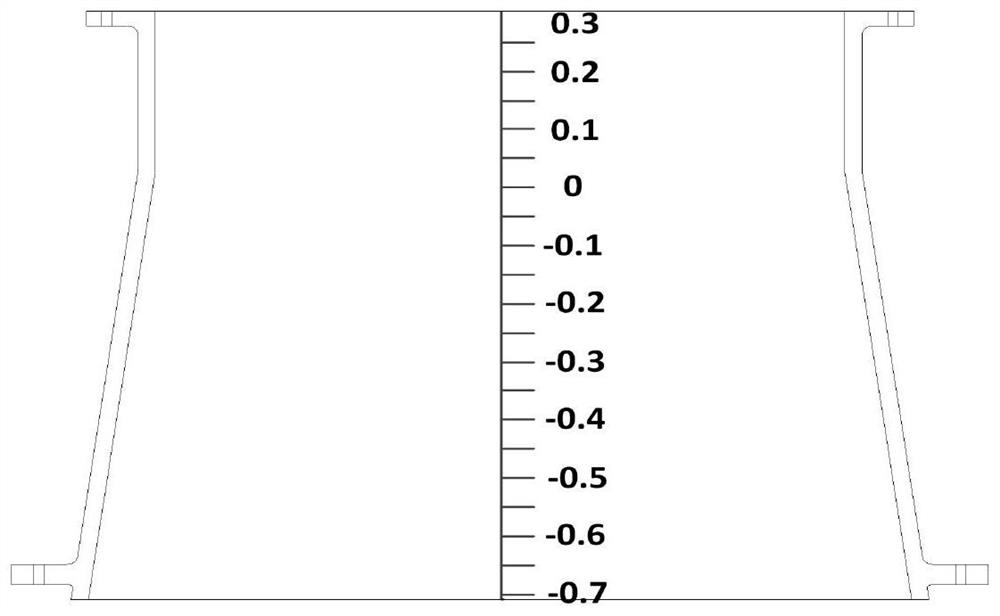

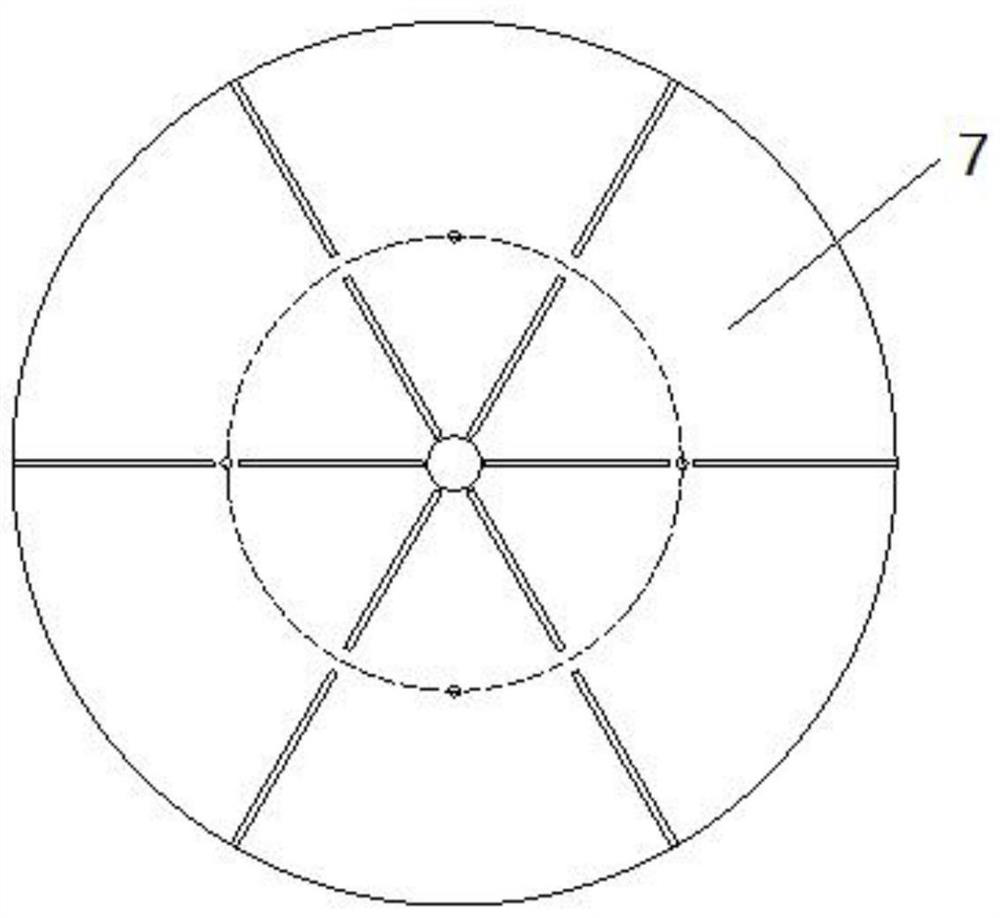

[0025] Such as Figures 1 to 4 As shown, a kind of experimental device of the present invention simulates the dynamic change of the material surface during the process of material falling in the furnace throat, and consists of four parts: the furnace throat furnace body part, the load-bearing platform part, the arc tray part and the charge recovery part from top to bottom. The upper part of the furnace throat body part is a small ring 1, the middle part is the furnace throat body body 2, the lower part is a large ring 3, and the bottom of the lower large ring is provided with eight uniform holes; the upper part of the load-bearing platform part is an outer The inner circular frame 4 is provided with eight uniform holes on the top to connect with the large ring 3 of the furnace throat and body part, and is tightly connected with bolts and nuts, and the bottom is provided with 4 uniform holes; the lower part of the load-bearing platform is A square frame 5, the upper part is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com