Battery coating film slurry, battery separator, secondary battery and preparation method thereof

A coating film and paste technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as imperfect microcrystalline structure, low crystallinity, and large internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

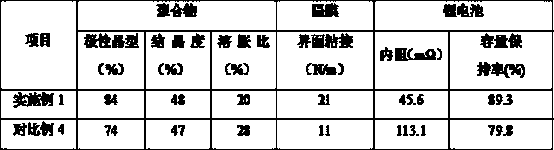

Examples

Embodiment 1

[0087] A preparation method of battery coating film slurry, comprising the steps of:

[0088] 1. Provide polymers;

[0089] 2. Provide organic-inorganic hybrid nucleating agents;

[0090] 3. Provide inorganic fillers;

[0091] 4. Prepare battery coating film slurry based on the materials provided above.

[0092] The polymer in step 1 is a fluoropolymer;

[0093] The fluorine-containing polymer is polyvinylidene fluoride.

[0094] The organic-inorganic hybrid nucleating agent is a phenyl polysiloxane hybrid nucleating agent.

[0095] The preparation method of phenyl polysiloxane hybrid nucleating agent, its concrete steps are:

[0096] (1) Dissolve benzoic acid in ice water to form a solution, add 3-aminopropyltriethoxysilane and ultrasonically dissolve it in a low temperature environment for 0.5 to 1 hour.

[0097] The various materials are counted in parts by mass, the parts by mass of benzoic acid are 5 parts by mass, and the parts by mass of ice water are 75 parts by ...

Embodiment 2

[0162] A preparation method of battery coating film slurry, comprising the steps of:

[0163] 1. Provide polymers;

[0164] 2. Provide organic-inorganic hybrid nucleating agents;

[0165] 3. Provide inorganic fillers;

[0166] 4. Prepare battery coating film slurry based on the materials provided above.

[0167] The polymer in step one is a fluoropolymer.

[0168] The fluorine-containing polymer is polyvinylidene fluoride.

[0169] The organic-inorganic hybrid nucleating agent is a long-chain alkylpolysiloxane hybrid nucleating agent.

[0170] The preparation method of long-chain alkyl polysiloxane hybrid nucleating agent, its specific steps are:

[0171] (1) Dissolve octadecyldimethylphosphoric acid directly in water to form a solution, add 3-glyceroloxypropyltrimethoxysilane and ultrasonically dissolve it in a low temperature environment for 0.5 to 1 hour.

[0172] Various materials are calculated according to mass parts, and the mass parts of octadecyl dimethyl phosph...

Embodiment 3

[0186] The invention provides a method for preparing battery coating film slurry, comprising the following steps:

[0187]1. Provide polymers;

[0188] 2. Provide organic-inorganic hybrid nucleating agents;

[0189] 3. Provide inorganic fillers;

[0190] 4. Prepare battery coating film slurry based on the materials provided above.

[0191] The polymer in step 1 is a fluoropolymer;

[0192] The fluorine-containing polymer is a copolymer based on vinylidene fluoride and methyl acrylate, wherein the mass fraction of vinylidene fluoride is 85%;

[0193] The organic-inorganic hybrid nucleating agent is a phenyl polysiloxane hybrid nucleating agent;

[0194] The preparation method of phenyl polysiloxane hybrid nucleating agent, its concrete steps are:

[0195] (1) Dissolve benzoic acid in ice water to make a solution, add 3-aminopropyltriethoxysilane and ultrasonically dissolve it in a low temperature environment for 0.5 to 1 hour;

[0196] Various materials are counted accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com