High-ammonia-nitrogen wastewater treatment device

A waste water treatment, high ammonia nitrogen technology, applied in the direction of coupling devices, parts of connecting devices, electrical components, etc., can solve the problems of inconvenient disassembly and maintenance, labor-intensive, hidden dangers, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

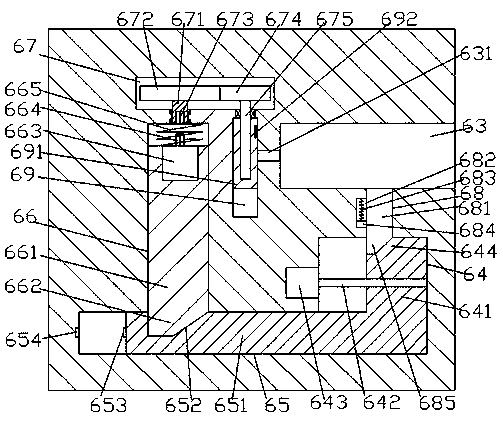

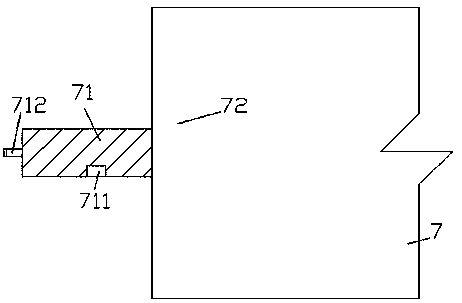

[0013] Combine below Figure 1-3 The present invention will be described in detail.

[0014] Reference Figure 1-3 , According to an embodiment of the present invention, a high ammonia nitrogen wastewater treatment device includes a clamping base 6 and a waste water treatment machine 7 for mating connection with the clamping base 6. The right end surface of the clamping base 6 is provided with There is an inserting groove 63, the lower side of the inserting groove 63 is provided with a first sliding compartment 64 in the clamping seat 6, and the inner bottom wall of the first sliding compartment 64 is provided with a first sliding compartment extending to the left side. In the second sliding compartment 65, a first through port 68 is provided in the part between the insertion groove 63 and the first sliding compartment 64, and the clamping seat 6 on the left side of the insertion groove 63 is provided with The third sliding compartment 69 is provided with a fourth sliding compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com