Container skid-mounted fire extinguishing system and manufacturing method thereof

A production method and technology of a fire extinguishing system, applied in the container skid-mounted fire extinguishing system and its production field, can solve problems such as unsuitable fire extinguishing materials, engine damage, heat conduction oil pipe damage, etc., and achieve shortened performance test/inspection time and compact configuration Space, the effect of improving shipbuilding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

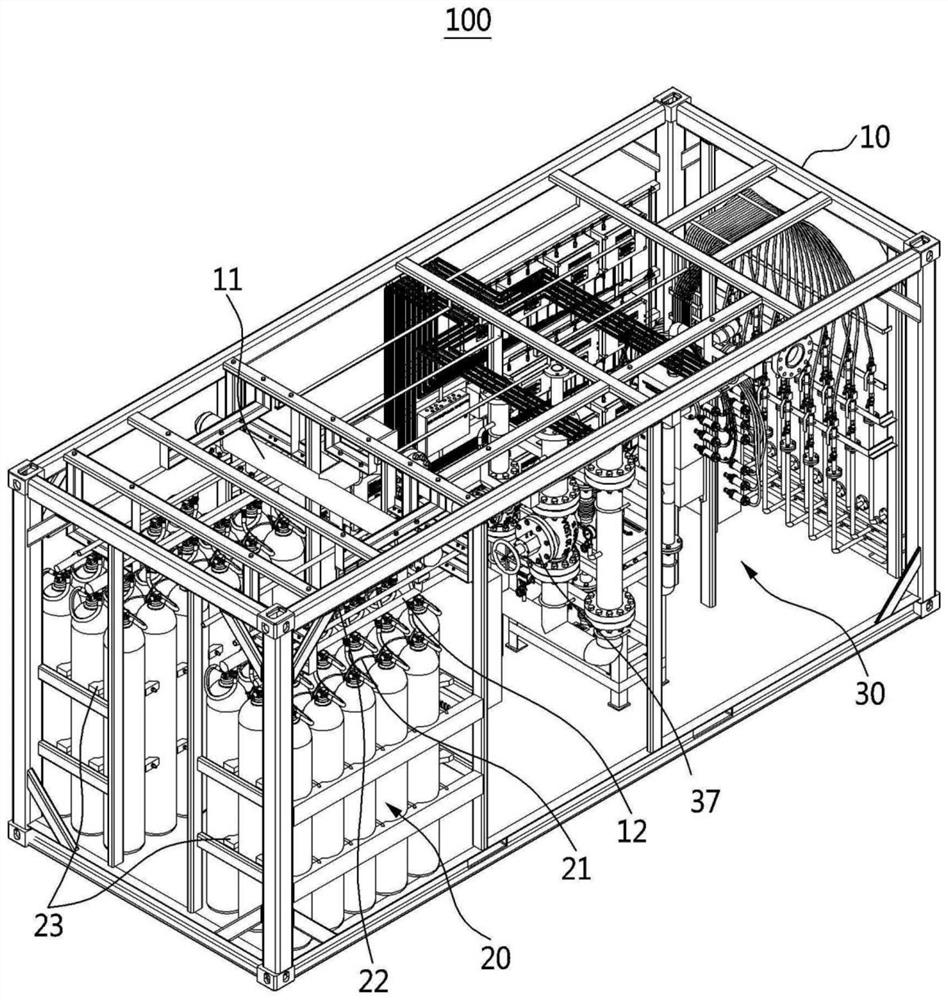

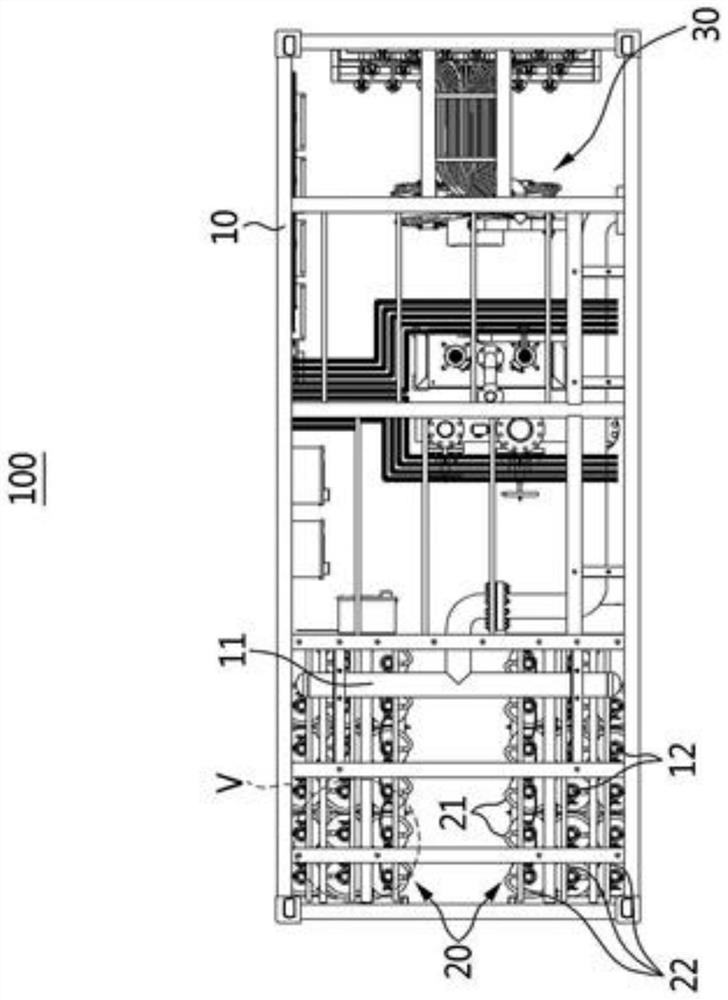

[0059] Hereinafter, a preferred embodiment of the present invention will be described with reference to the drawings. However, the idea of the present invention is not limited to these embodiments, and the idea of the present invention can be realized in various ways by adding, changing, and deleting structural elements constituting the embodiments, but this is also included in the scope of the present invention. in thought.

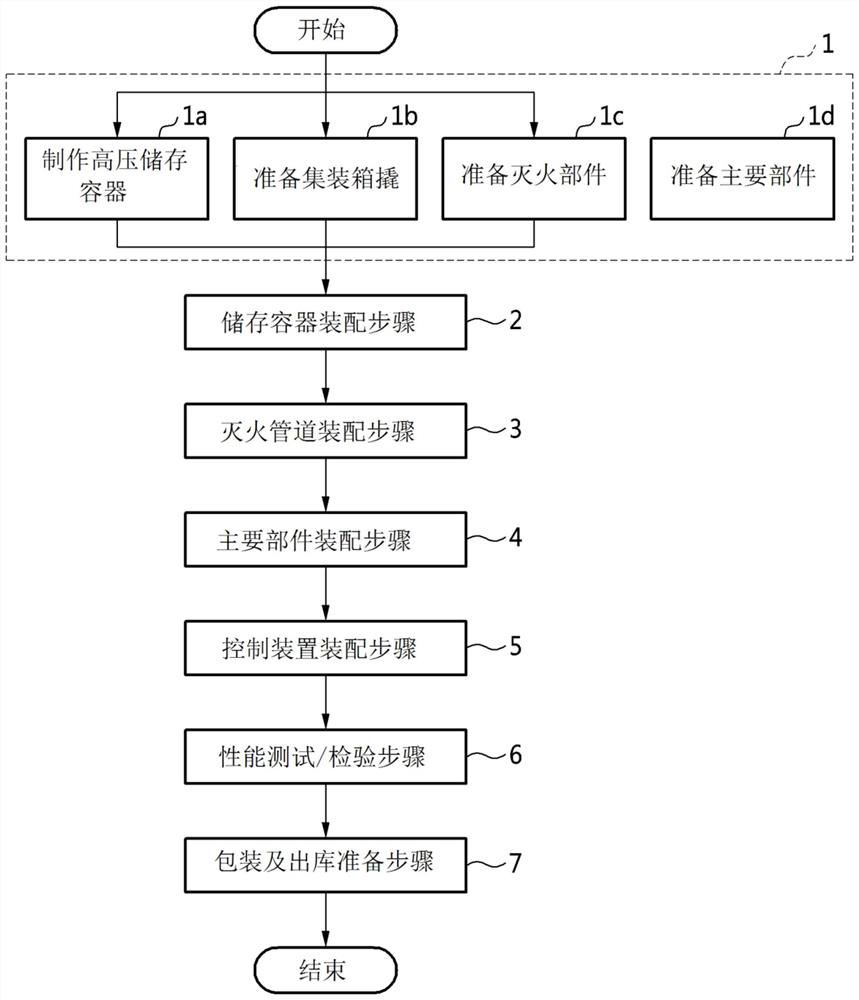

[0060] figure 1 The specific steps of the manufacturing method of the container skid-mounted fire extinguishing system according to a preferred embodiment of the present invention are shown.

[0061] refer to figure 1 , the manufacturing method of the container skid-mounted fire extinguishing system includes: preparation step 1, storage container assembly step 2, fire extinguishing pipeline assembly step 3, main component assembly step 4, control device assembly step 5, performance test / inspection step 6, and packaging / Outbound preparation step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com