Circuit substrate transportation vehicle with dust removal function

A circuit substrate and function technology, applied in printed circuits, printed circuit manufacturing, trolleys, etc., can solve problems such as affecting quality and breakage, and achieve the effects of improving work efficiency, solving deformation, and improving quality stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

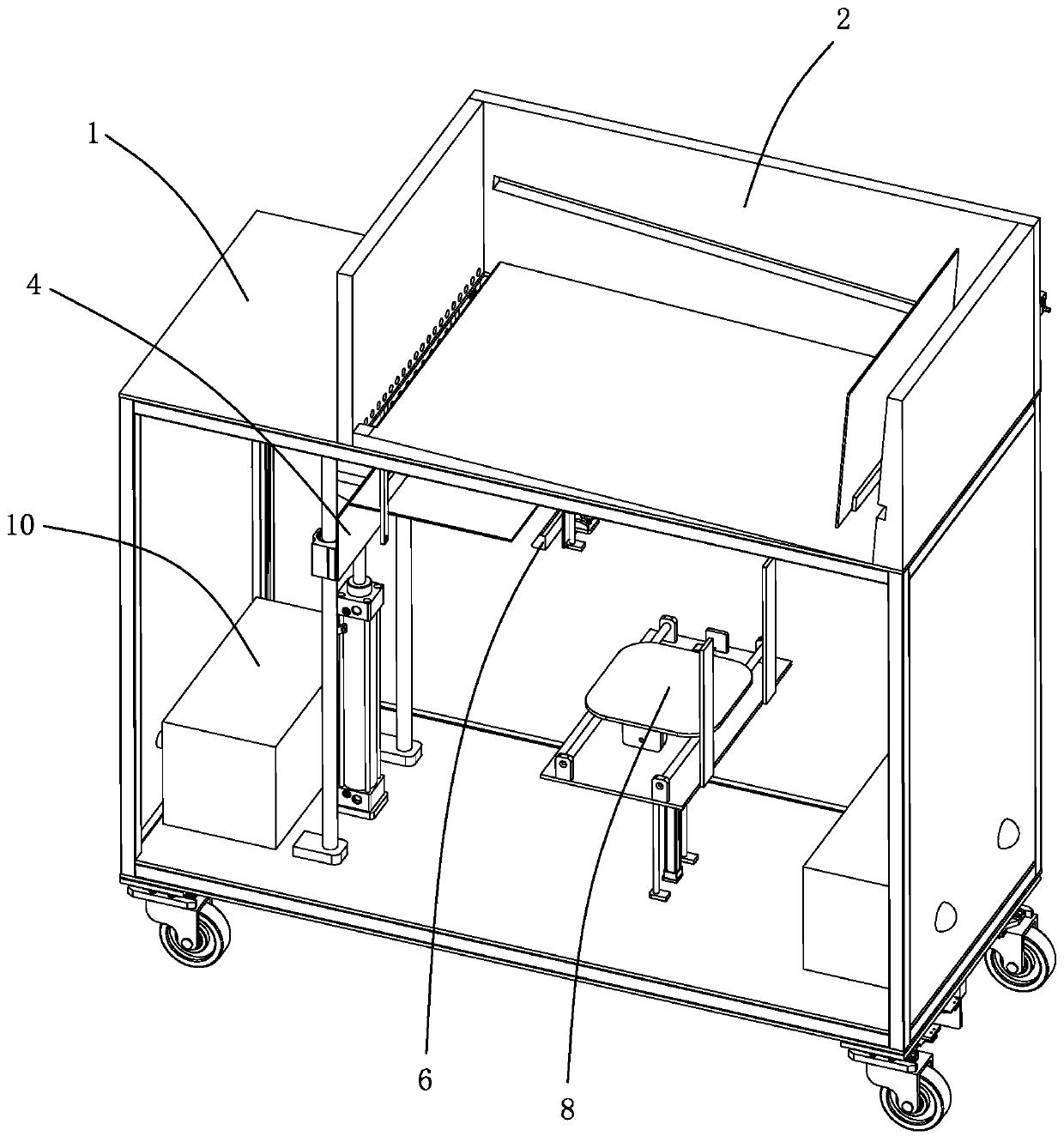

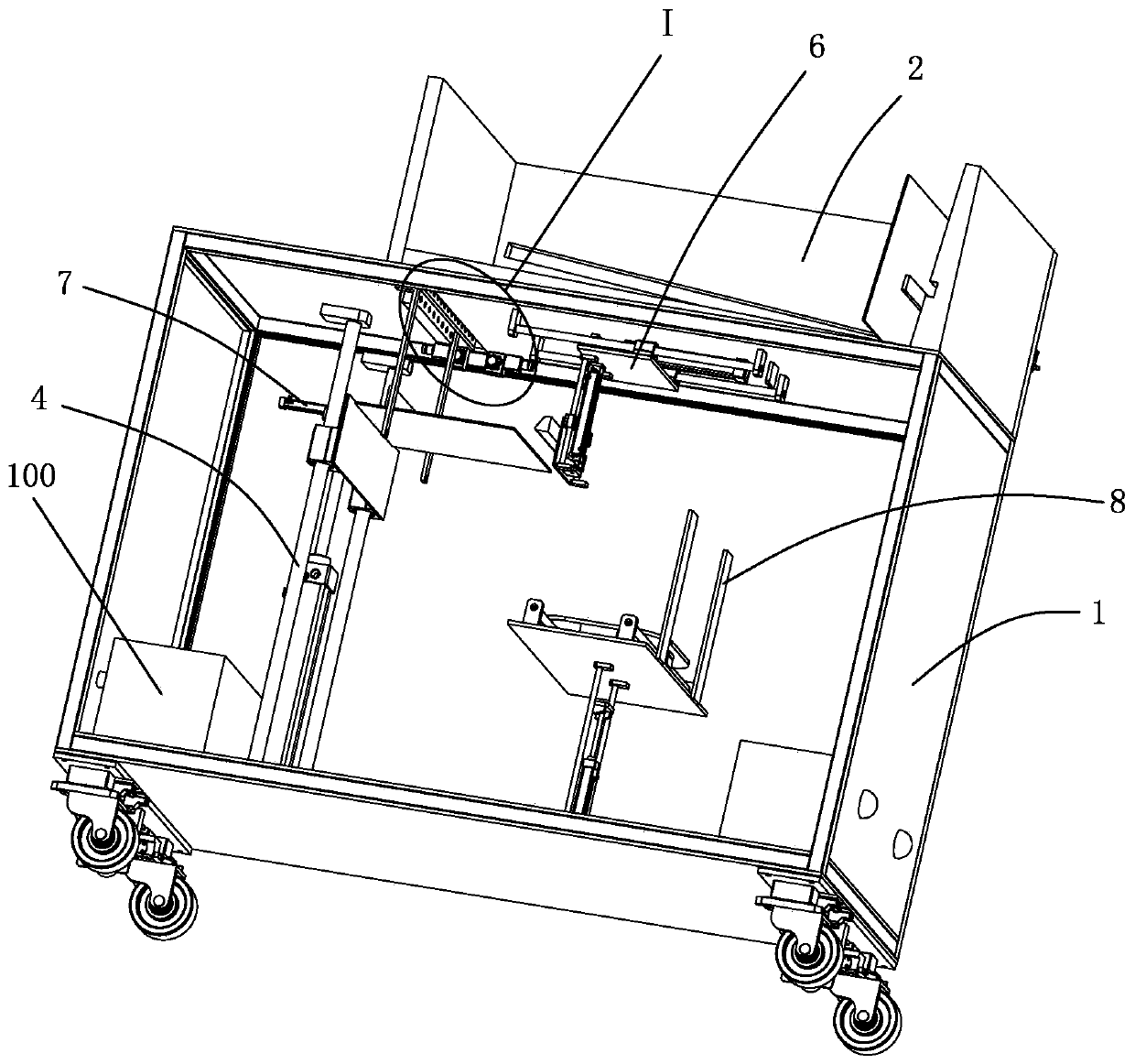

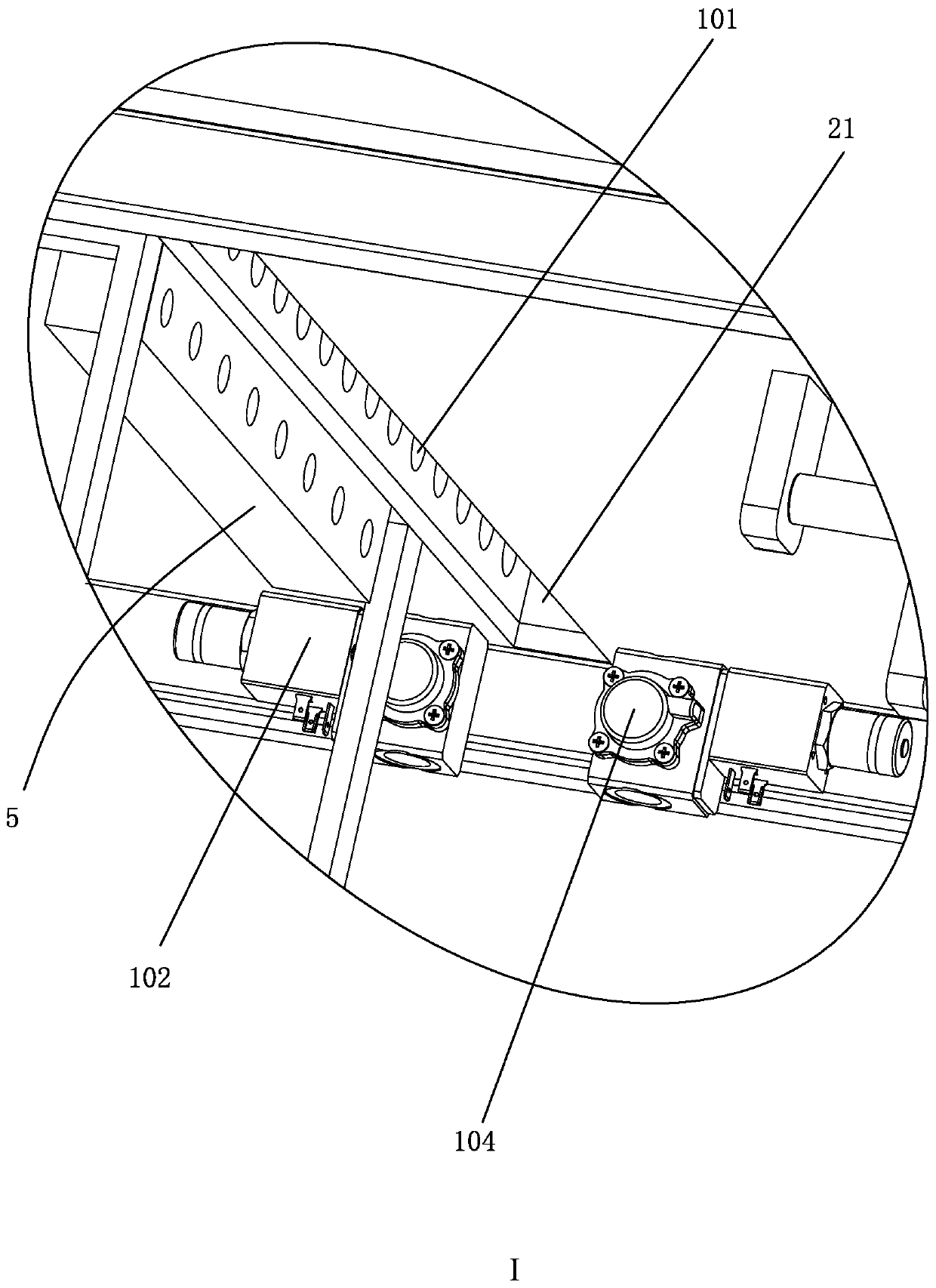

[0071] Such as Figure 1-13 As shown above, the circuit board carrier with dust removal function includes a body 1, a placement chamber 2, a left push mechanism 3, an air blowing dust removal mechanism 10, a receiving mechanism 4, a blowing mechanism 5, a buffer mechanism 6, and a pushing mechanism 7 , Mobile loading platform 8, photoelectric switch group 9.

[0072] Specifically, the placement chamber 2 is provided on the upper side of the body 1 for placing circuit substrates, and a communication slot 21 communicating with the inside of the body 1 is opened on the left side of the bottom. The left pushing mechanism 3 is arranged on the rear side of the placement chamber 2, and its pushing end extends into the placement chamber 2, and is used to push the circuit board to the left so that the circuit board passes through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com