Container type movable surfacing equipment

A container-type, container-based technology, which is applied in the field of container-type mobile surfacing equipment, to achieve the effects of reducing equipment maintenance costs, reversing cargo and making on-site preparations simple, and saving on-site construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A container-type mobile surfacing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

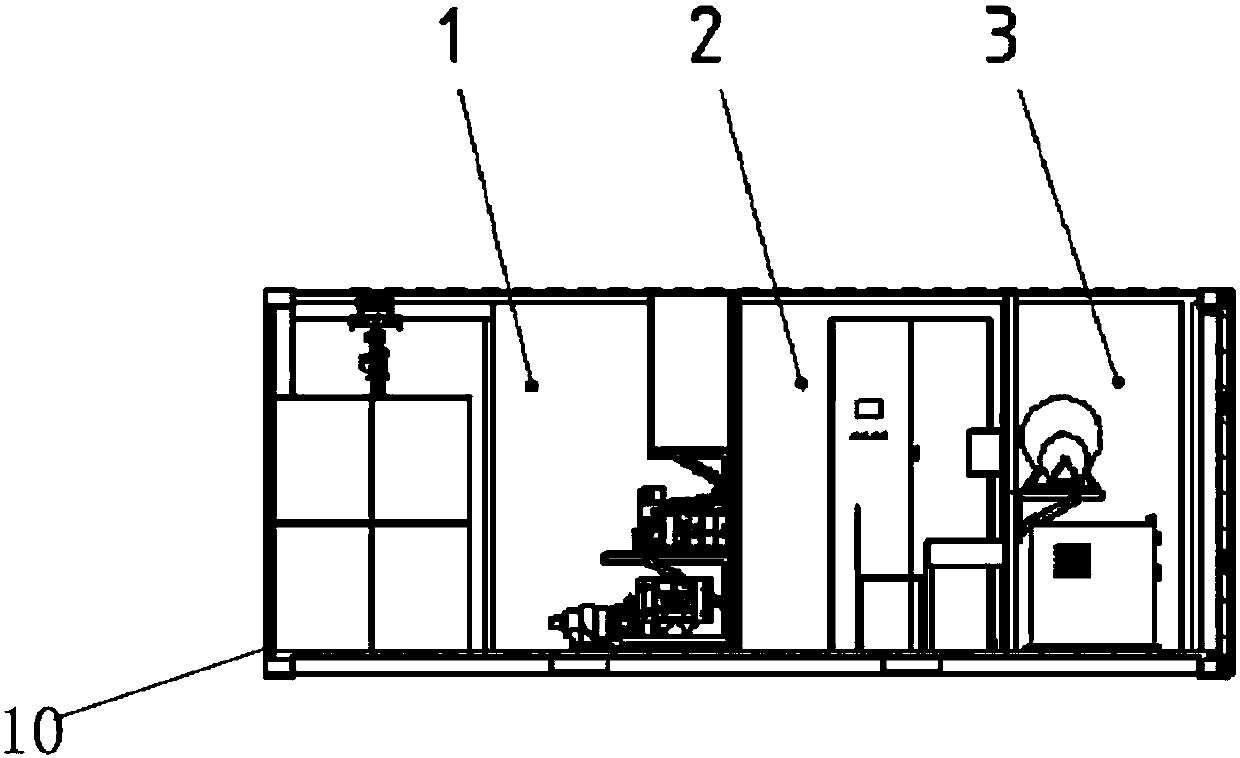

[0026] figure 1 Shown, a container-type mobile surfacing equipment, including a container body 10, is characterized in that, the container body 10 includes a first functional area 1, a second functional area 2 and a third functional area 3, wherein the first The functional area 1 , the second functional area 2 and the third functional area 3 are arranged inside the container body 10 and arranged in sequence.

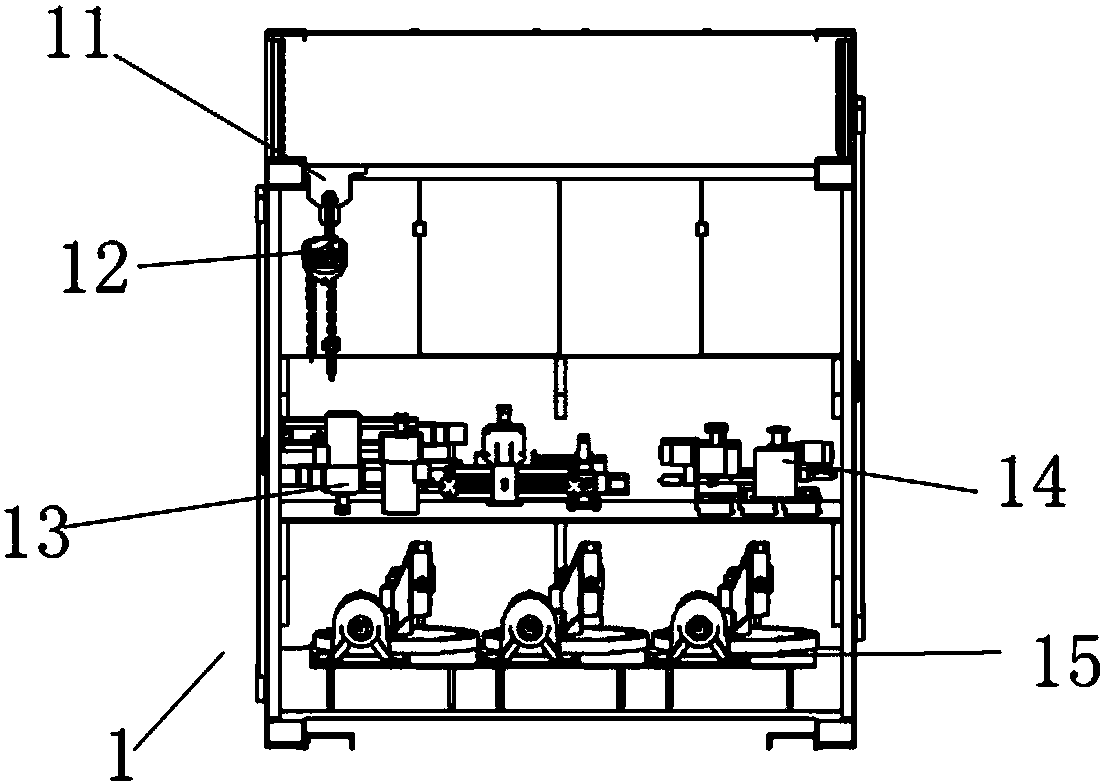

[0027] figure 2 As shown, the top of the first functional area 1 is provided with a slide rail 11 and a lifting device 12; the middle part is provided with a cleaning device 13 and a welding torch traveling mechanism 14; the lower part is provided with a grinding roller driving device 15 and a motor.

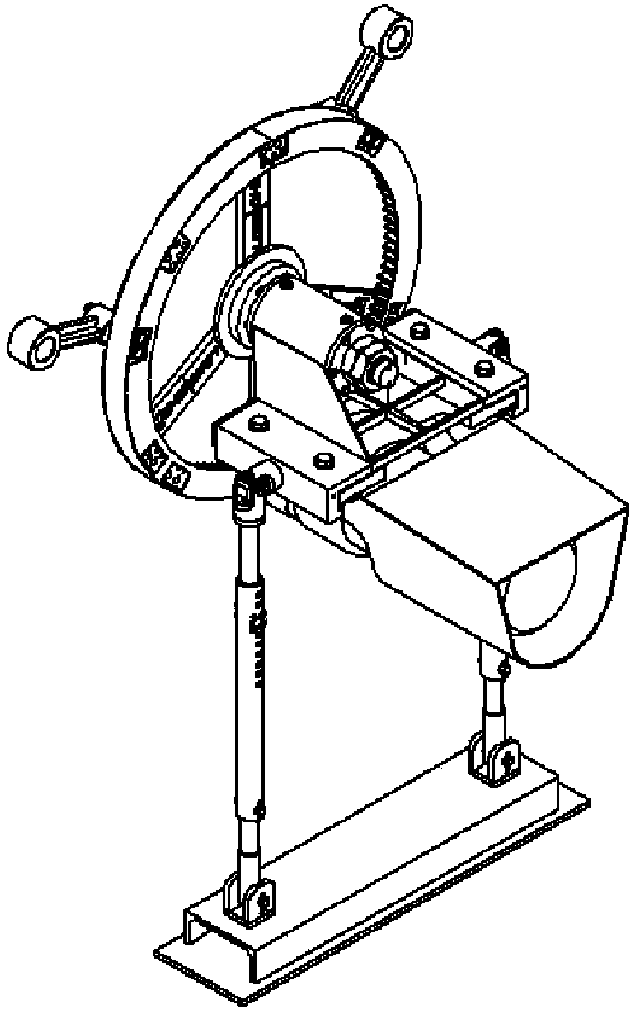

[0028] image 3 Shown, cleaning device 13 comprises driving motor 131, track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com