Shot-blasting reinforcing jig

A shot peening and jig technology, applied in the field of jig, can solve the problem of low shot peening efficiency and achieve the effect of improving shot peening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

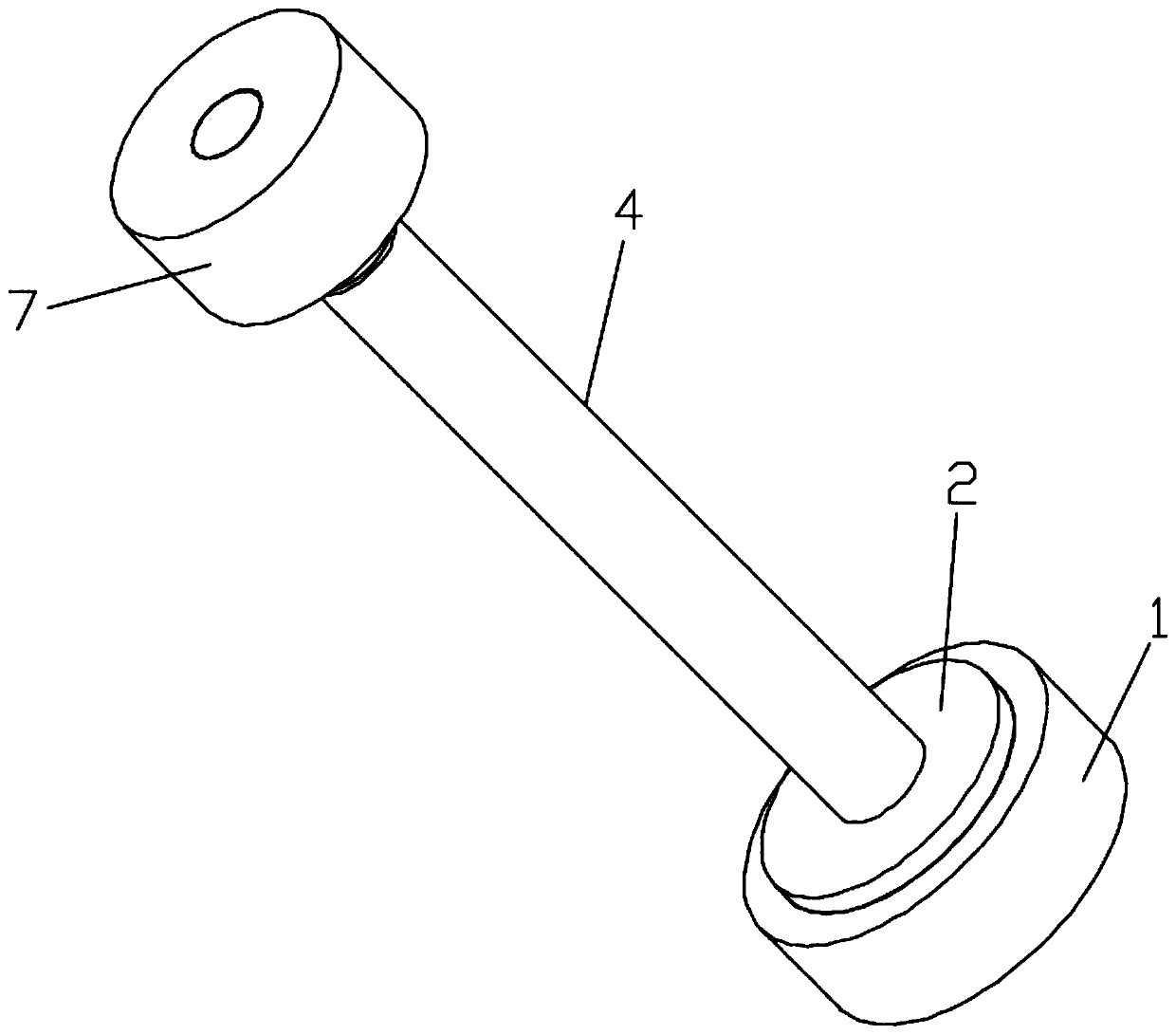

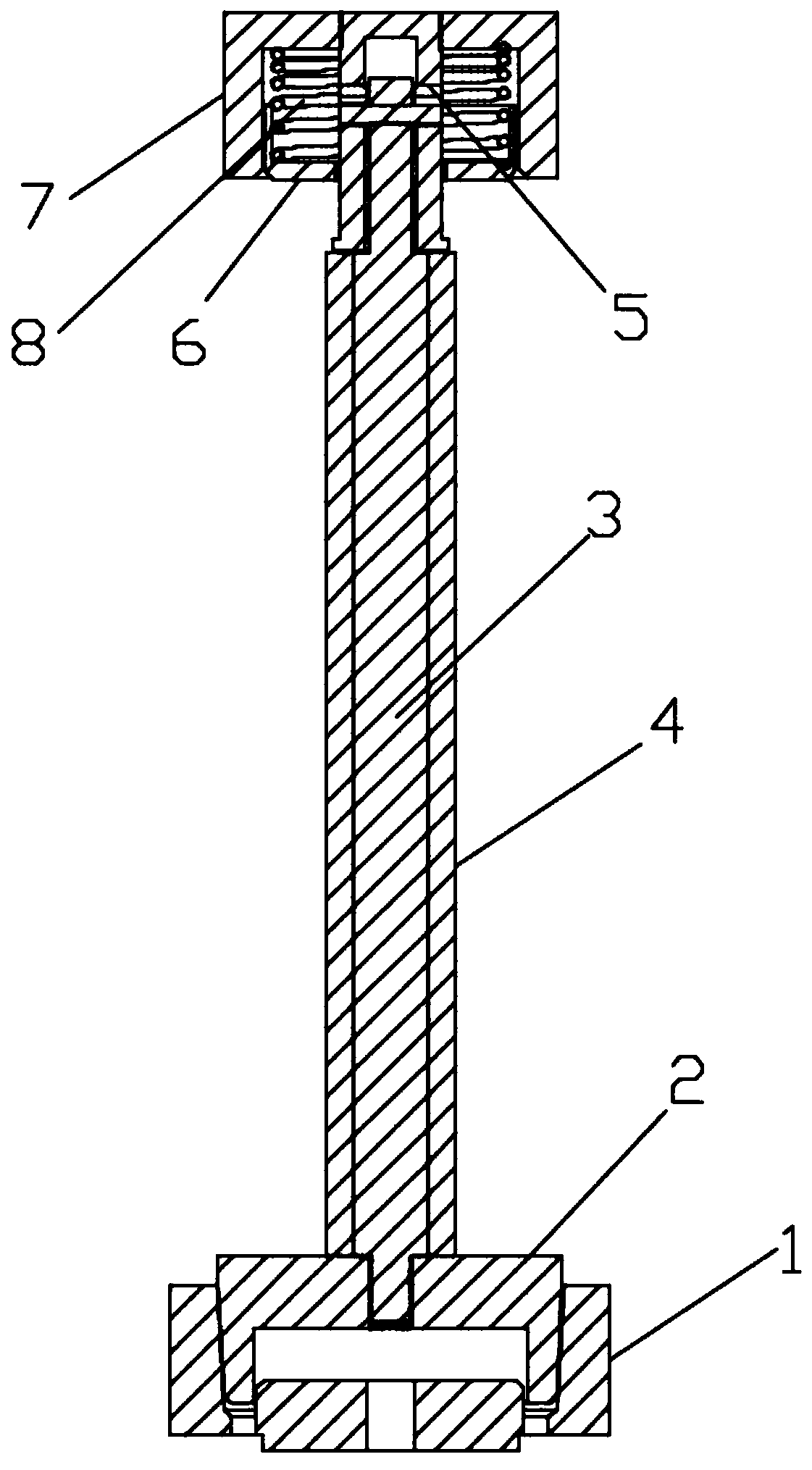

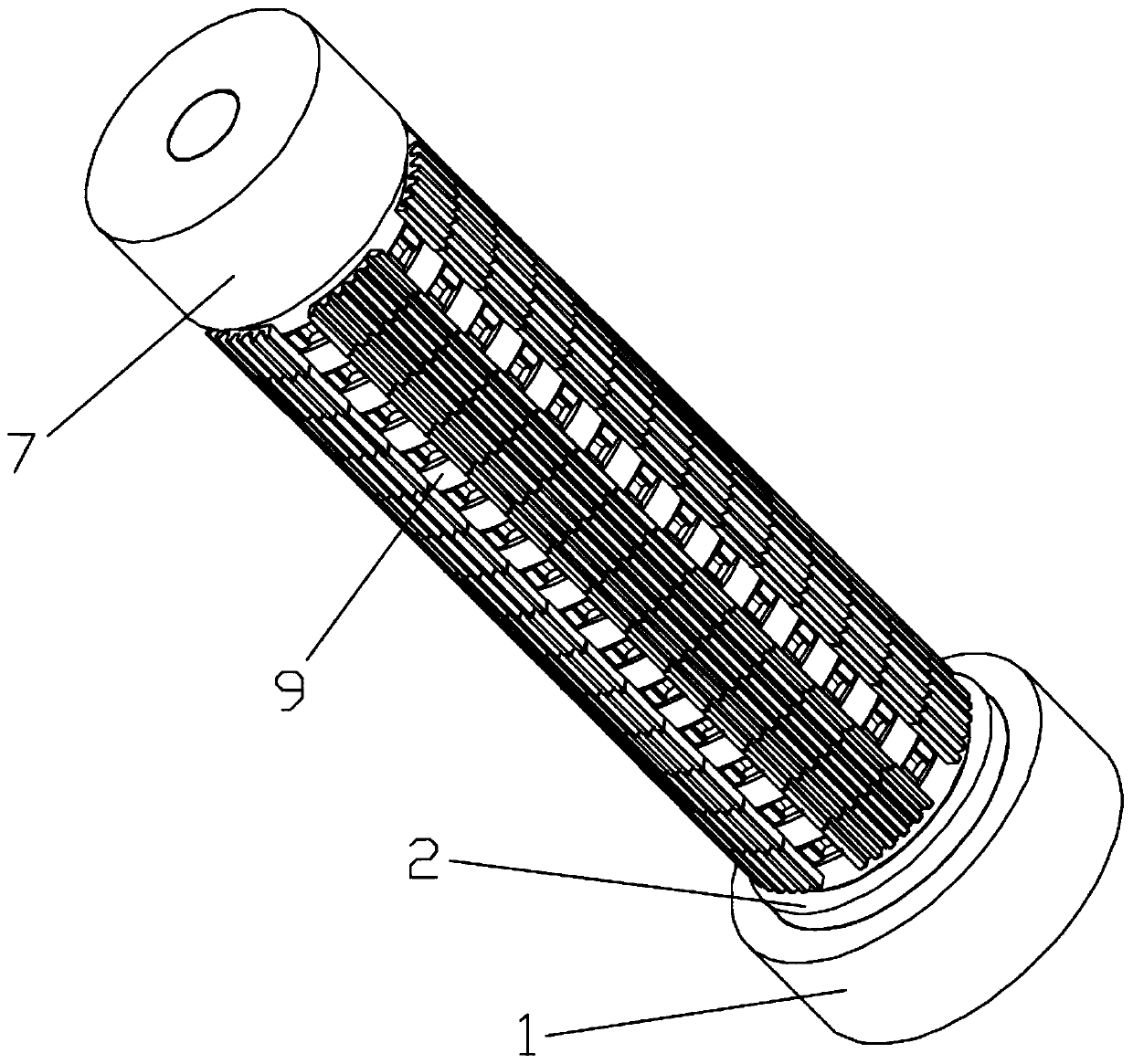

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 is a sectional view of the present invention, image 3 It is a structural schematic diagram of the present invention after the gear hub is loaded.

[0021] A shot peening strengthening fixture, comprising a fixed base 1, a bottom connecting seat 2, a central fixing rod 3, a protective sleeve 4, a connecting sleeve 5, an inner gland 6, an outer gland 7 and an elastic device 8, the bottom is connected The seat 2 is placed in the base 1, the bottom end of the central fixed rod 3 is fixedly connected to the bottom connecting seat 2, the central fixed rod 3 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com