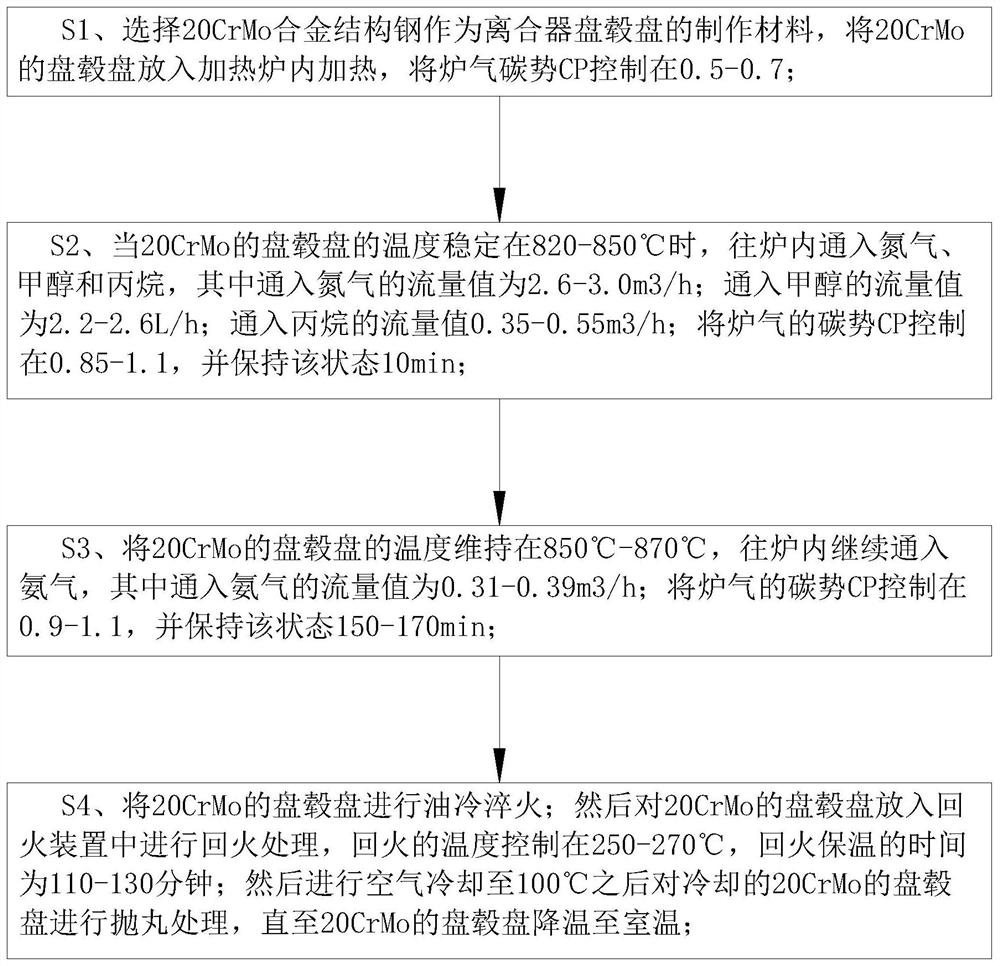

A heat treatment process for a clutch disc hub

A technology for clutch discs and hubs, which is applied in the heat treatment process of clutch discs and hubs, can solve the problems of affecting the fatigue resistance and service life of workpieces, incomplete internal stress of hubs, and low production efficiency, so as to increase tempering and shot peening effect, increased quality and service life, increased production quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

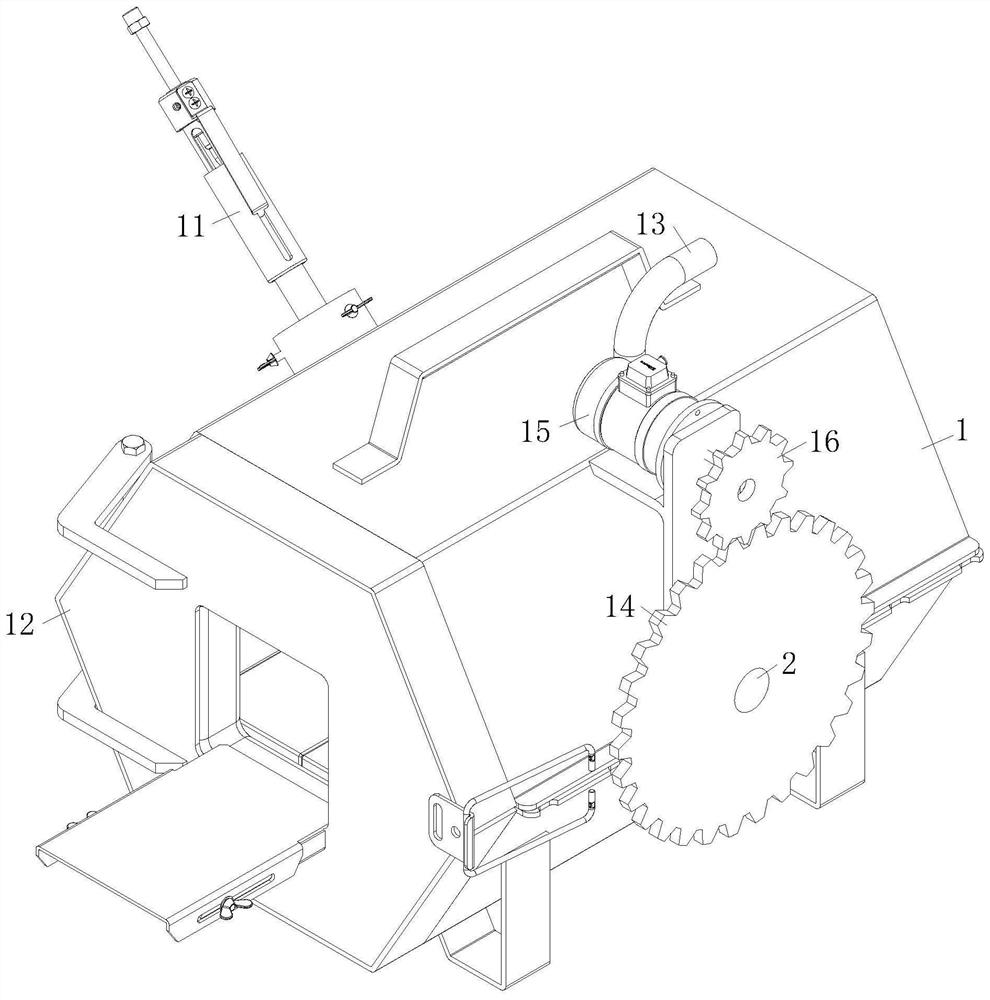

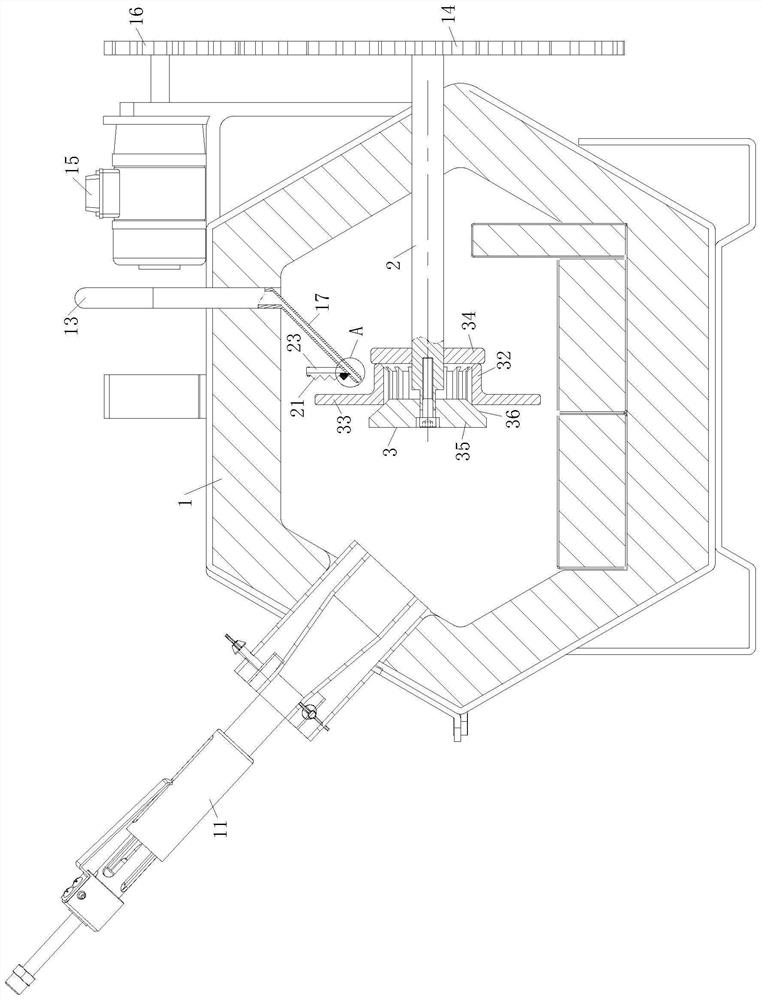

[0032] As an embodiment of the present invention, the hub disc includes a hub 32 and a disc 33; the outlet of the nozzle 17 is aligned with the connecting portion of the hub 32 and the disc 33, and the impact of iron shot on the hub 32 and the disc 33 is increased. The beating frequency of the connection part of the hub can further release the residual stress; due to the sudden change in the thickness of the hub 32 and the disc 33, the stress at the hub 32 and the disc 33 in the hub is relatively concentrated, and the outlet of the nozzle 17 is aligned. The connection between the hub 32 and the disk 33 makes the iron pellets ejected at a high speed from the nozzle 17 hit the connection between the hub 32 and the disk 33 in large quantities, so that the stress of the connection between the hub 32 and the disk 33 is fully released, increasing the The strength uniformity between the hub 32 and the disc 33 further releases the residual stress and increases the stress release effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com