Method for processing heavy diesel oil

A diesel and heavy-weight technology, applied in the field of oil refining, can solve the problem of difficult to guarantee the operation cycle of the device, and achieve the effects of long operation cycle of the device, high gasoline yield and high content of aromatics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

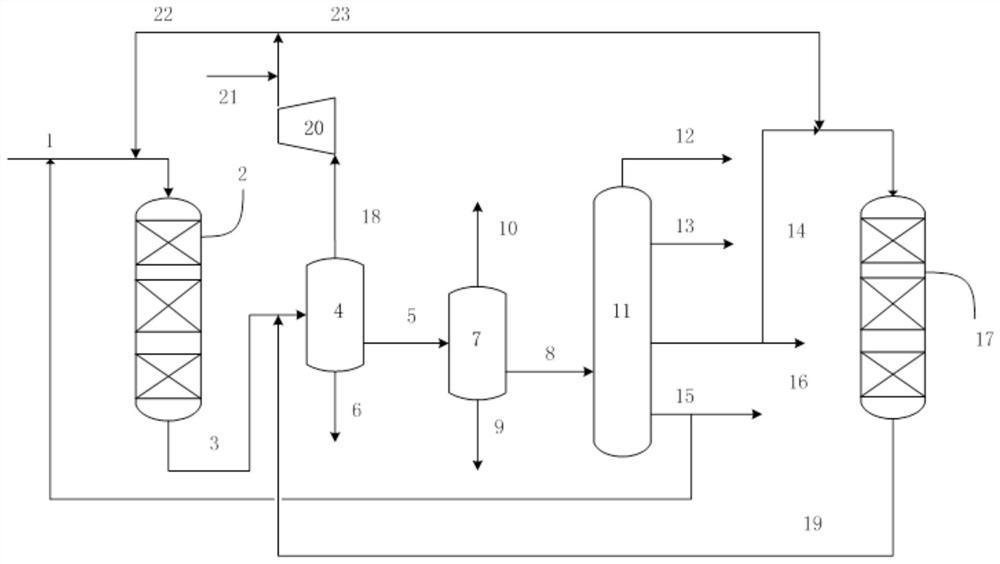

Image

Examples

specific Embodiment approach

[0044] The first type: preferably in step (3), a part of the light hydrogenated diesel oil is introduced into the hydrocracking reactor to carry out the second contact reaction with the hydrocracking catalyst contained therein, and the remaining part of the light hydrogenated diesel oil As the hydro-upgraded diesel output device, and the liquid effluent from the hydrocracking reactor in step (4) is introduced into step (2), to be combined with the liquid effluent from the step (2) The liquid effluents in the hydrofinishing reactor are introduced together into the same separation and fractionation system for separation and fractionation.

[0045] In the first preferred embodiment, the light hydrogenated diesel introduced into the hydrocracking reactor is 20-50% by weight of the heavy diesel feedstock in step (1).

[0046] The second type: preferably in step (3), all of the light hydrogenated diesel oil is introduced into the hydrocracking reactor to carry out the second contact...

Embodiment 1

[0091] use figure 1 The process shown treats feed oil D.

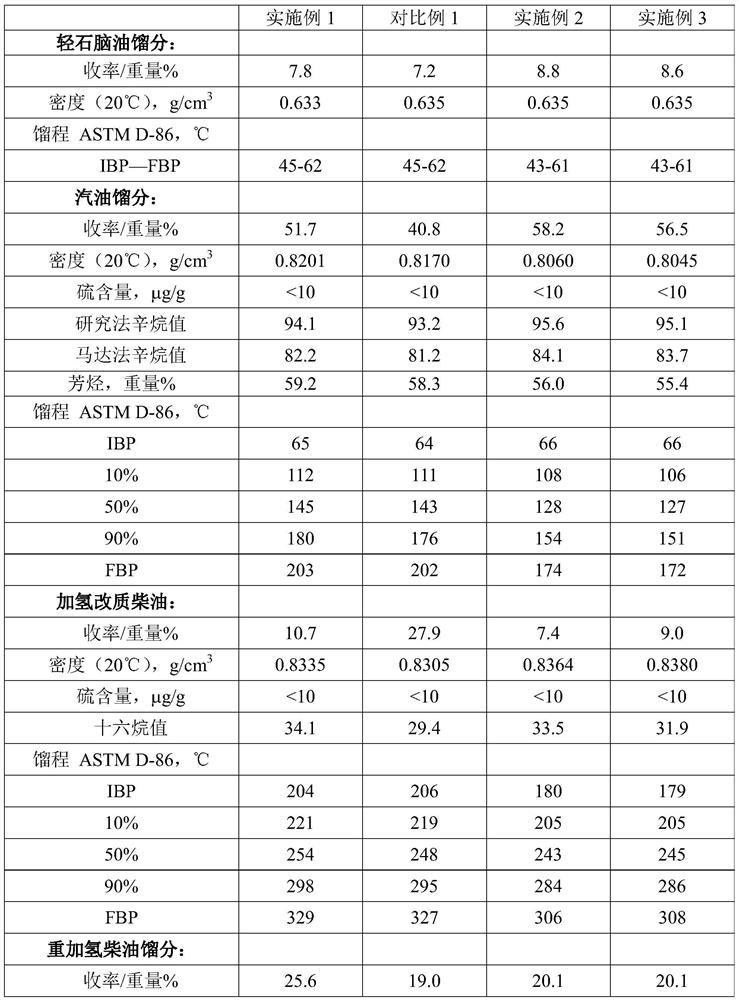

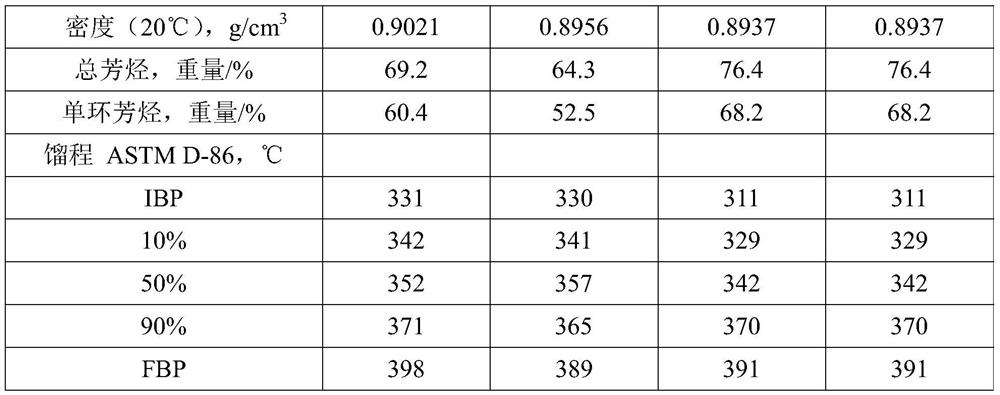

[0092] The raw oil D is firstly contacted with the hydrofinishing catalyst A through the hydrofinishing reactor, and the heavy hydrogenated diesel oil fraction with a boiling point higher than 320°C is mixed with hydrogen and then refined back to the hydrofinishing reactor, wherein the content of single-ring aromatics is 66% by weight %, the proportion of back refining accounts for 20% by weight of the stock oil D. Part of the light hydrogenated diesel fraction with a boiling point less than 320°C is mixed with circulating hydrogen and then enters the hydrocracking reactor to contact with hydrocracking catalyst C. The circulation ratio accounts for 35% by weight of the feed oil D. , Fractional distillation to obtain light naphtha, gasoline fraction and hydrotreated diesel oil. Concrete reaction conditions are shown in Table 2, and product yield and properties are shown in Table 3.

Embodiment 2

[0097] use figure 1 The process shown treats feed oil E.

[0098] The raw material oil E is firstly contacted with the hydrofinishing catalyst A through the hydrofinishing reactor, and the heavy hydrogenated diesel oil fraction with a boiling point higher than 330°C is mixed with hydrogen and then returned to the hydrofinishing reactor. 15% by weight. Part of the light hydrogenated diesel fraction with a boiling point less than 330°C is mixed with circulating hydrogen and enters the hydrocracking reactor to contact with hydrocracking catalyst C. The circulation ratio accounts for 25% by weight of the feed oil E. , Fractional distillation to obtain light naphtha, gasoline fraction and hydrotreated diesel oil. Concrete reaction conditions are shown in Table 2, and product yield and properties are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com