Steel structure building verticality detection device

A detection device and verticality technology, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of inaccurate and error detection of verticality, and achieve the effects of improving safety, reducing work intensity, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

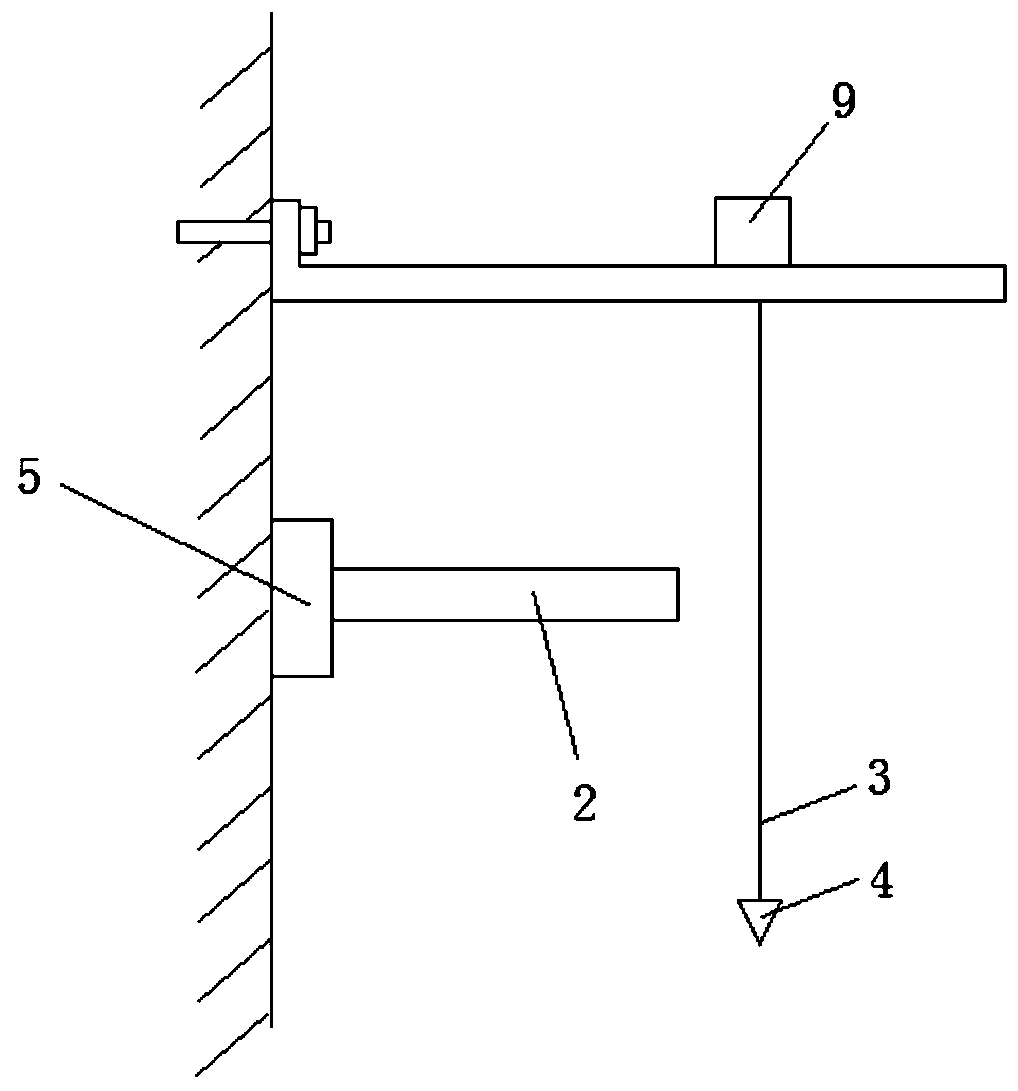

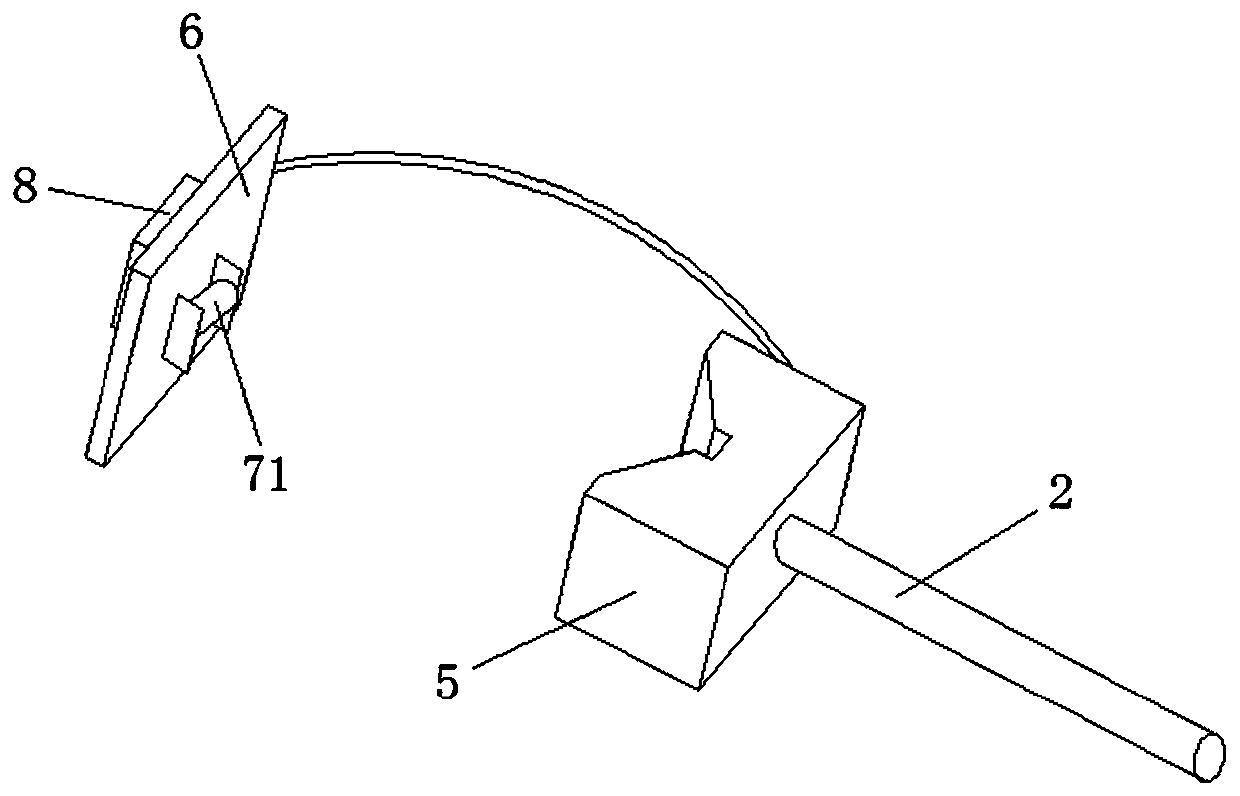

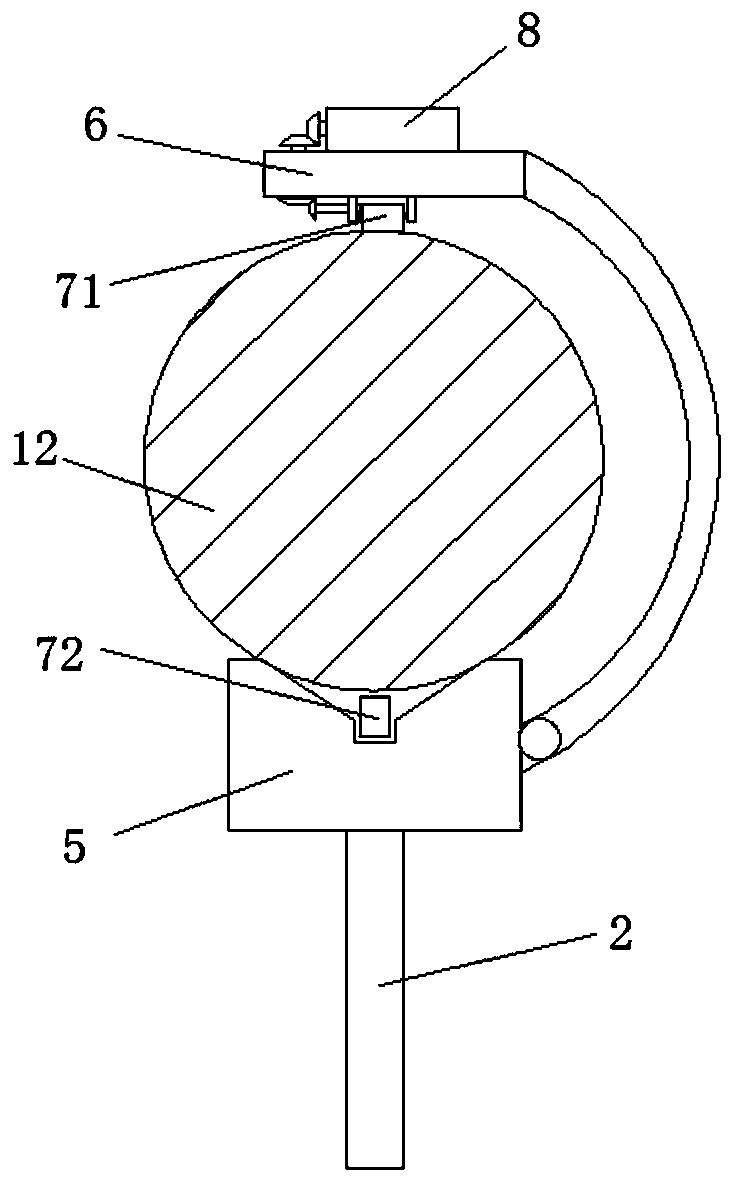

[0038] Embodiment 1, with reference to Figure 1 to Figure 3 as shown,

[0039] A verticality detection device for a steel structure building, comprising a boom 1 and a detection device 2; wherein,

[0040] The boom 1 is provided with a wire hammer 4 and a suspension wire 3, the wire hammer 4 is connected to the boom 1 through the suspension wire 3, and the detection device 2 slides vertically along the measured object 12 to detect the distance between the suspension wire 3 and the measured object 12;

[0041] The detection device is provided with a V-shaped block 5 , the opening side of the V-shaped block 5 faces the side of the measured object 12 , and the detection device 2 is clamped on the measured object 12 through the opening, and slides vertically along the measured object 12 .

[0042] Through the verticality detection device of a steel structure building with the above structure, when in use, the technician can attach the opening of the V-shaped block 5 to the side wa...

Embodiment 2

[0055] Embodiment 2 refers to Figure 1 to Figure 5 as shown,

[0056] The implementation principle and technical effect of the device provided by the embodiment of the present invention are the same as those of Embodiment 1. For a brief description, reference may be made to the corresponding content in Embodiment 1 for the parts not mentioned in this embodiment.

[0057] The device obtained through the above design can basically meet the use of the steel structure building verticality detection device, but in line with the purpose of further improving its function, the designer has made further improvements to the device.

[0058] Further, the boom 1 of the steel structure building verticality detection device is provided with a take-up device 9, and the above-mentioned suspension wire 3 is connected to the boom 1 through the take-up device 9; the take-up device 9 can realize the free movement of the suspension wire 3. retractable, so that the steel structure building vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com