Semiconductor failure location test unit and failure location method thereof

A technology of failure location and test unit, which is applied in semiconductor/solid-state device testing/measurement, semiconductor devices, semiconductor/solid-state device components, etc., which can solve the problem of time-consuming and labor-intensive capture of failure locations, FA failure location, and unfavorable FIB interception of separated areas And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

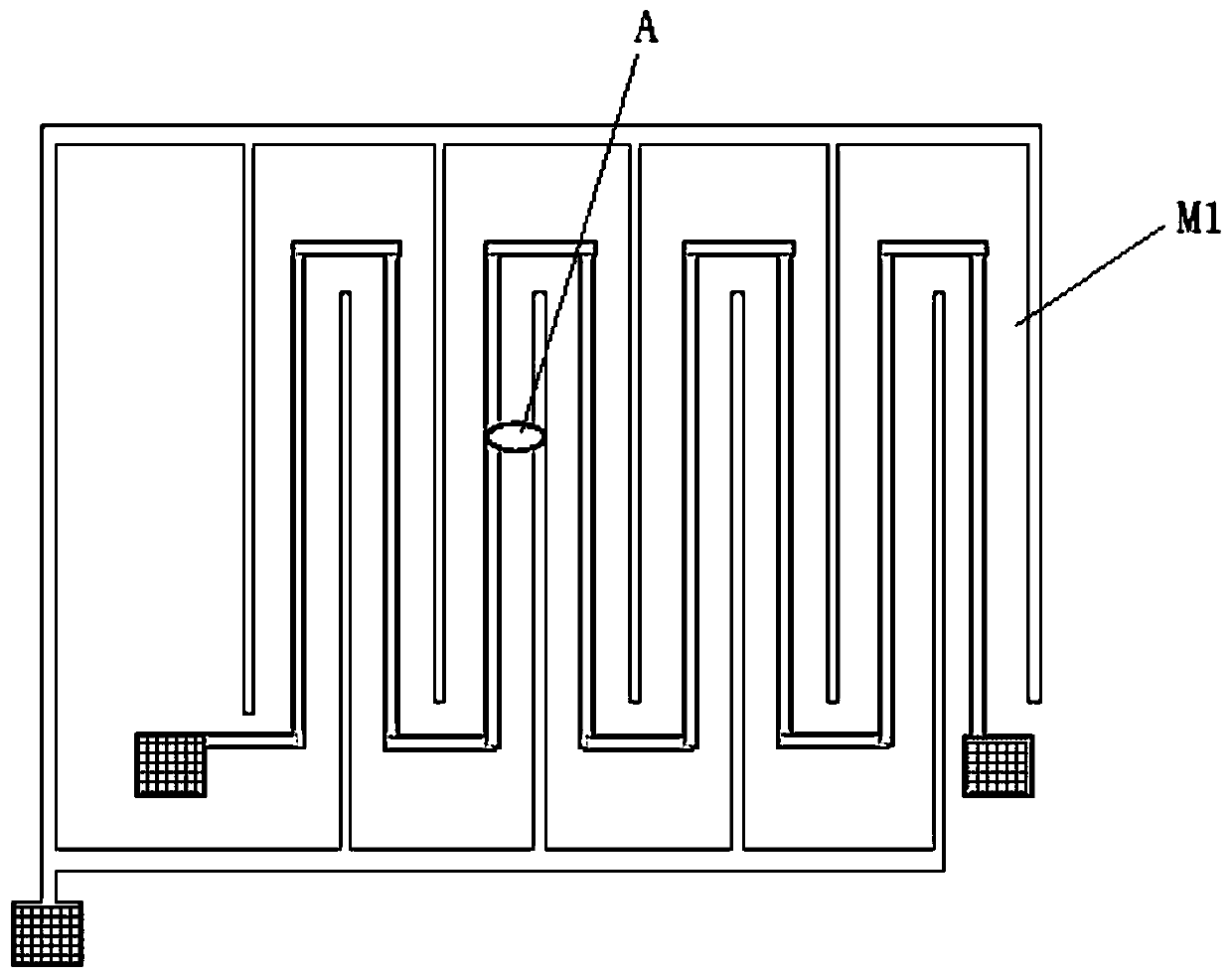

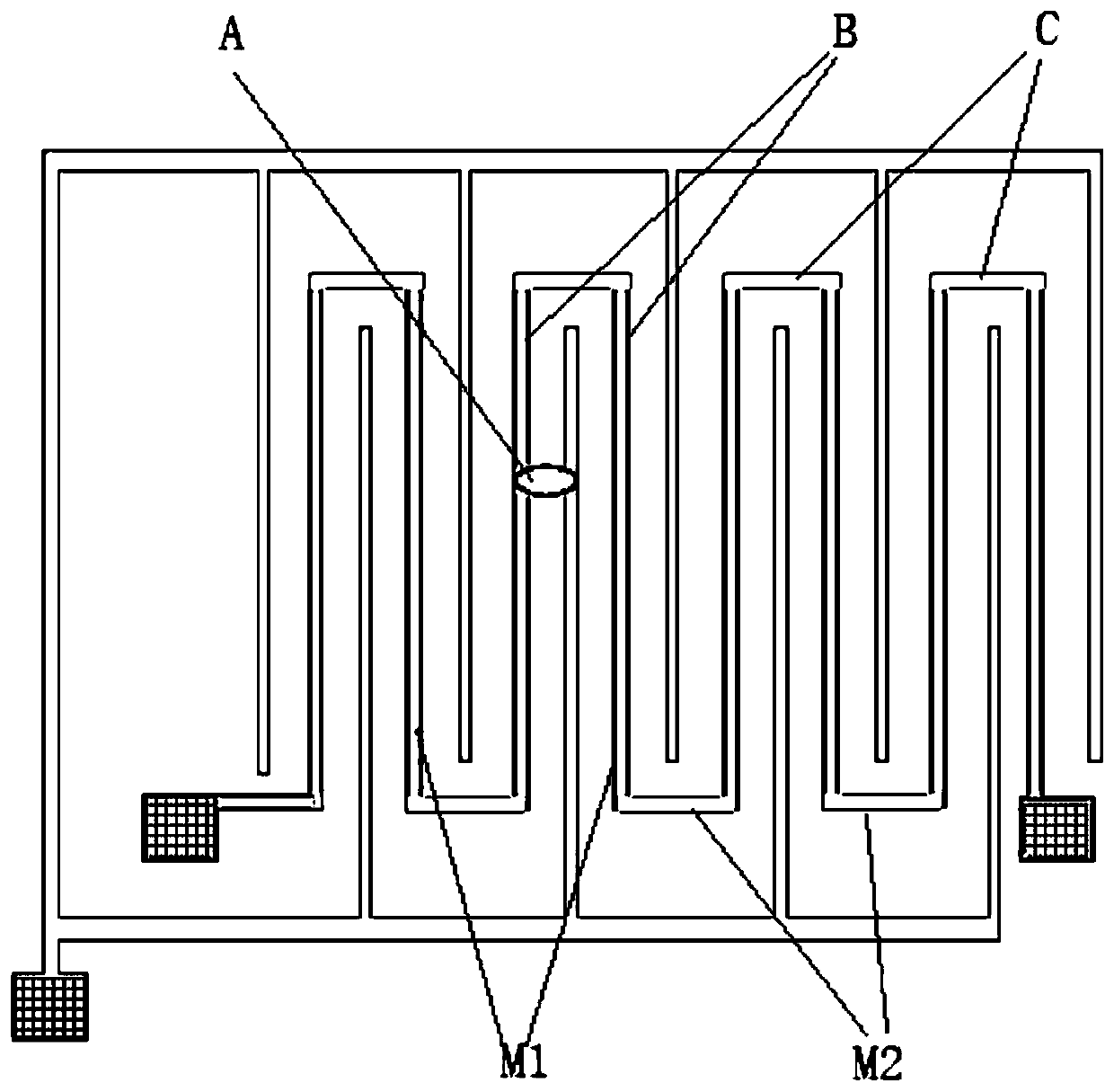

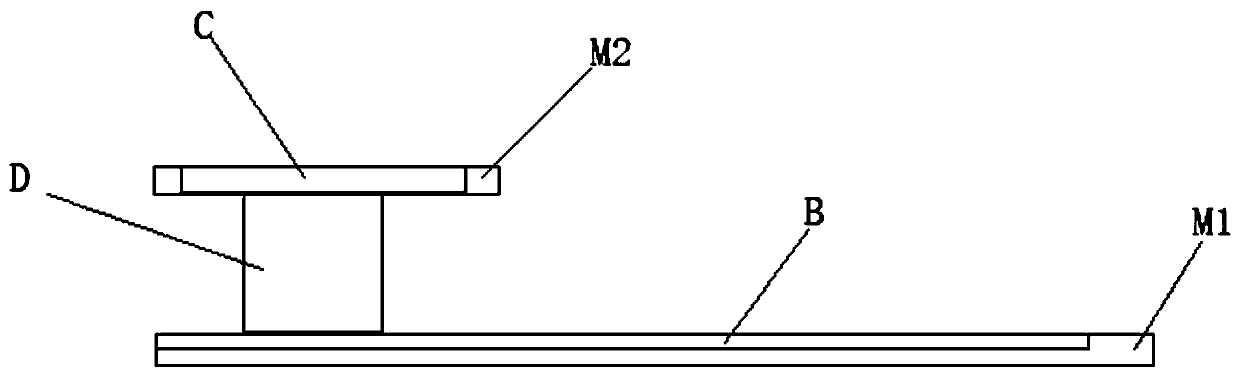

[0032] Such as figure 2 , image 3 As shown, the first embodiment of the semiconductor failure localization test unit (Snake-Comb testkey) provided by the present invention, the test unit is a comb structure located in the metal layer, and the bonding wire of the test unit is divided into the first Type bonding wire B and second type bonding wire C, adjacent first type bonding wires B are connected by second type bonding wire C, the length of the first type bonding wire B is longer than the second type class bonding wire C;

[0033] The applicant's division of the first type of bonding wire B and the second type of bonding wire C is based on figure 2 Take an example for further explanation. The arrangement direction of the first type of bonding wire B is the first direction, figure 2 Middle is the vertical direction. The arrangement direction of the second type of bonding wire C is the second direction, figure 2 Middle is the horizontal direction. The second type of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com