Fruit picking device

A fruit and pulley technology, applied in the direction of picking machines, agricultural machinery and tools, applications, etc., can solve the problems of development system limitations or high production costs, slow progress of picking robots, and failure to put into production, etc., to improve the cutting effect , reduced size, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

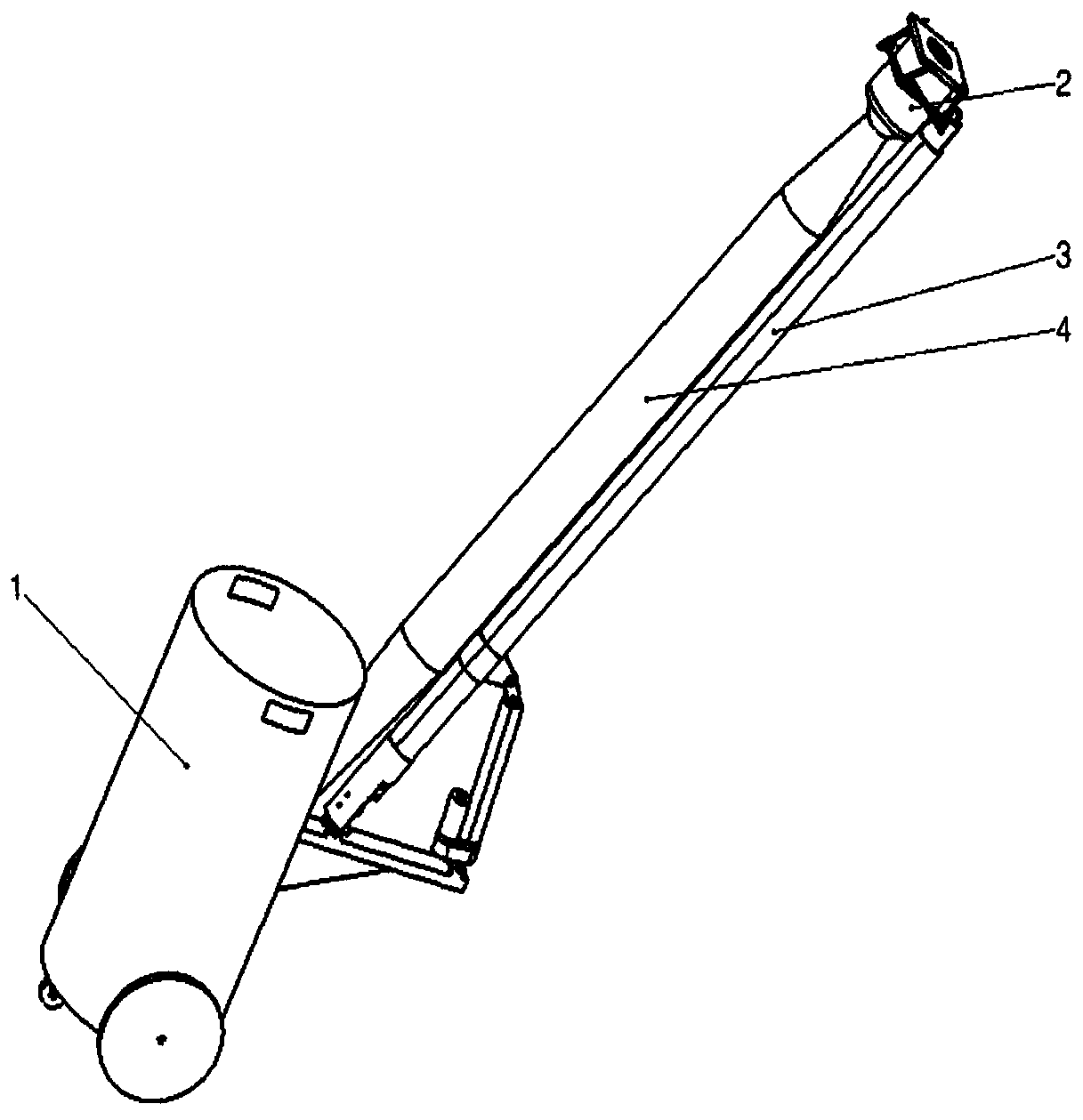

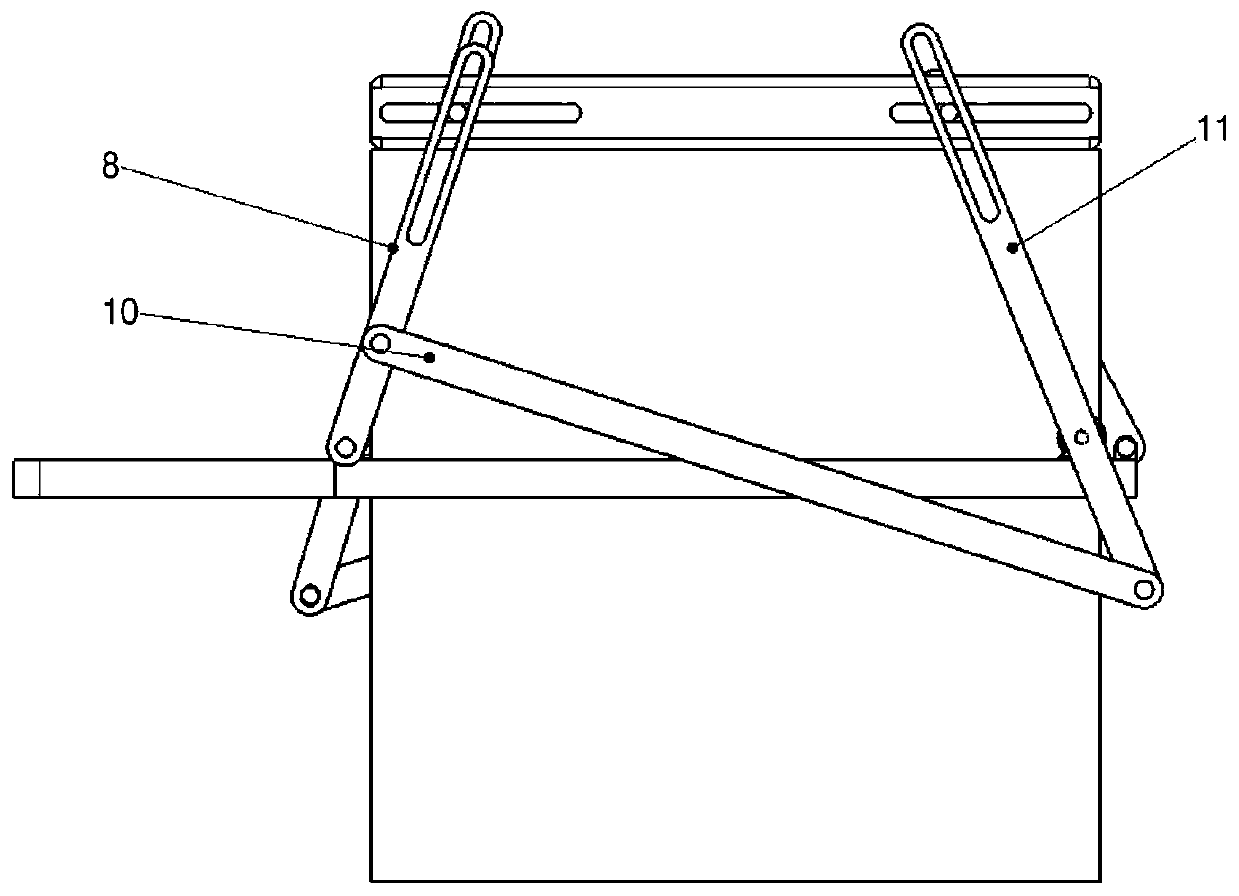

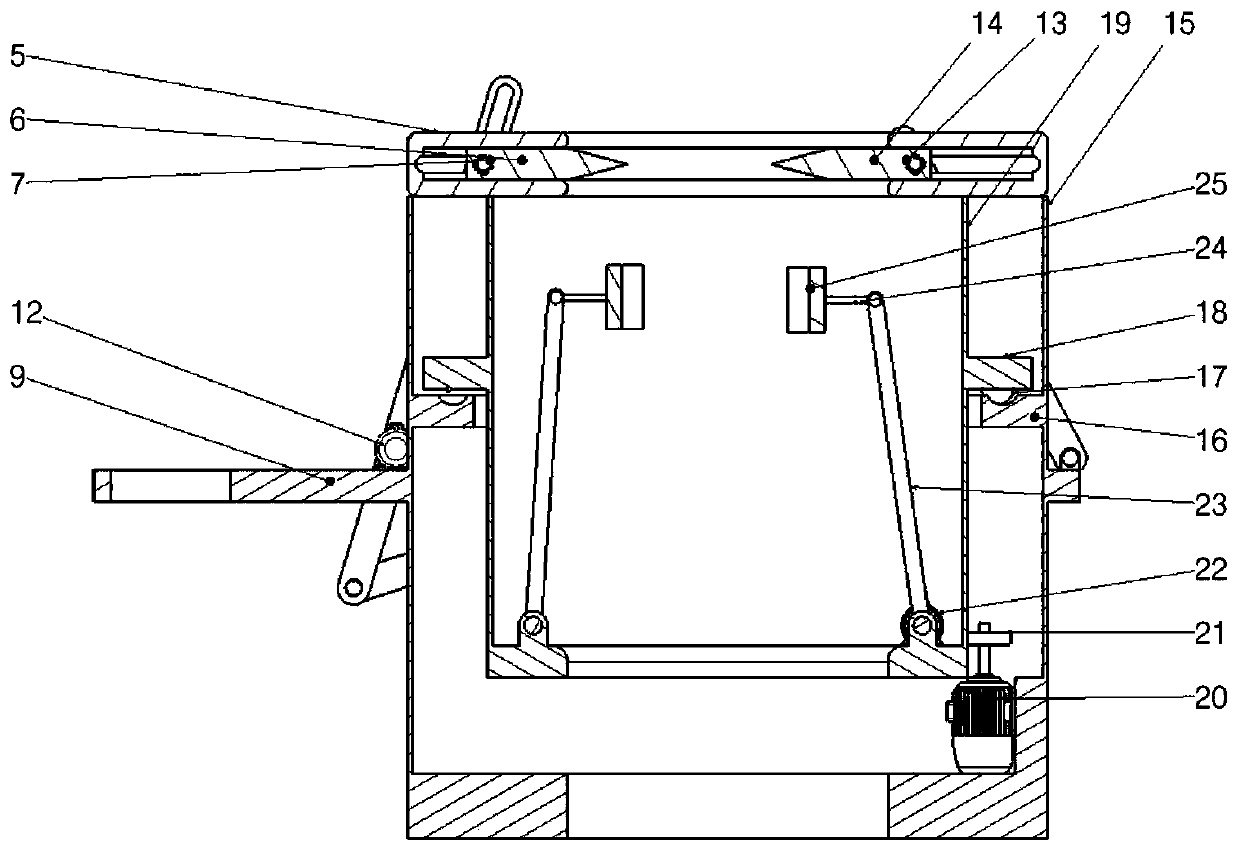

[0027] Such as figure 1As shown, the present invention relates to a kind of fruit picking device, and its feature is mainly made up of collecting trolley, picking mechanism, telescoping mechanism, conveying mechanism, and collecting trolley mainly drives differential gear through motor and cooperates with universal wheel as device to realize movement before and after movement and Left and right turning function; the picking mechanism mainly realizes cutting by shearing and twisting. The former cuts the fruit handle through the shearing force of the blade, and the latter maintains the shearing force through the blade. The clamping device clamps the fruit to the inner barrel The rotation cooperates to twist the fruit handle, so as to achieve the shearing effect; the telescopic mechanism drives the movement of the two-section arm through the screw rod, and the movement of the two-section arm drives the movement of the built-in pulley block to realize the synchronous movement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com