Harvesting trolley of an adaptive vibrating harvester

A vibrating, self-adaptive technology, applied in the field of agriculture and forestry, can solve the problems of low fruit picking efficiency, achieve the effects of reducing workload, improving picking efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

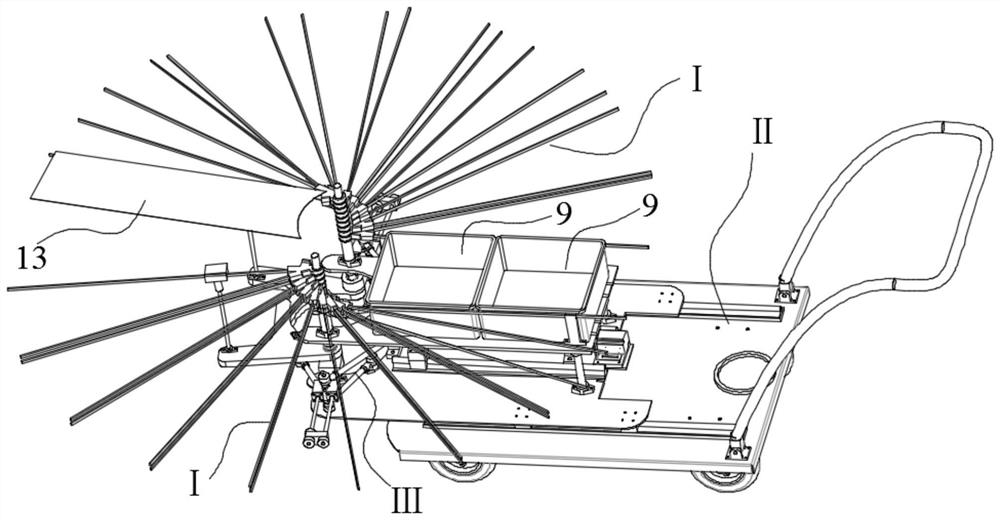

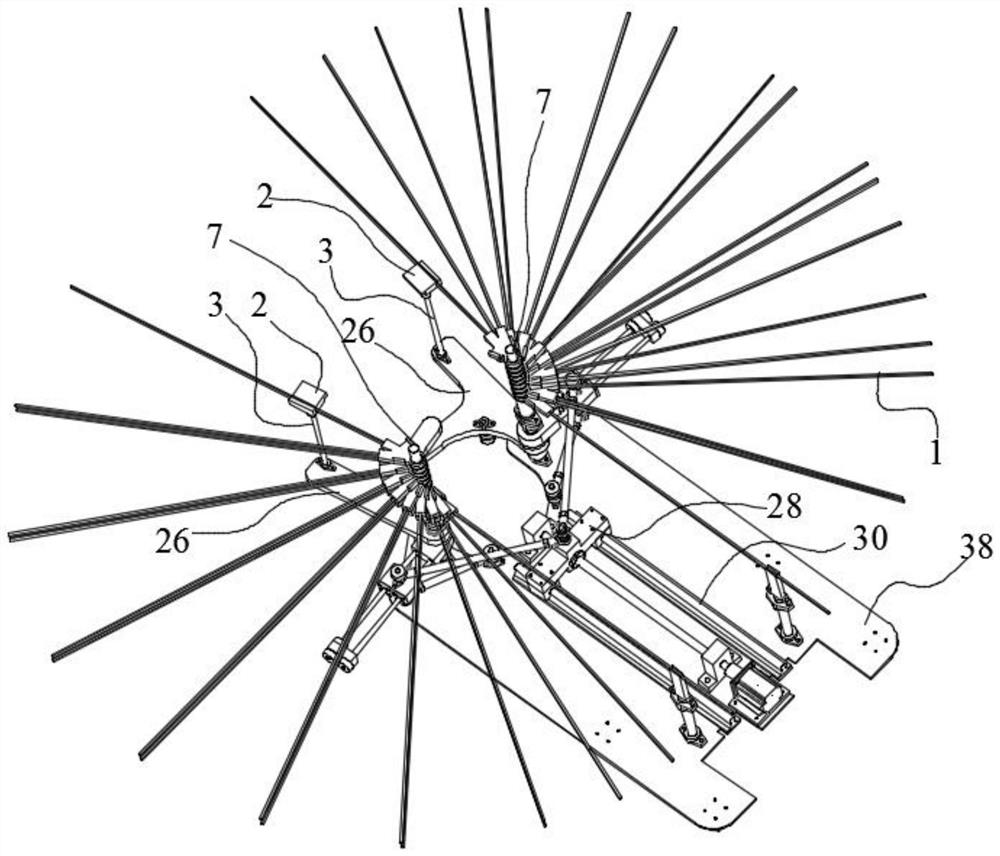

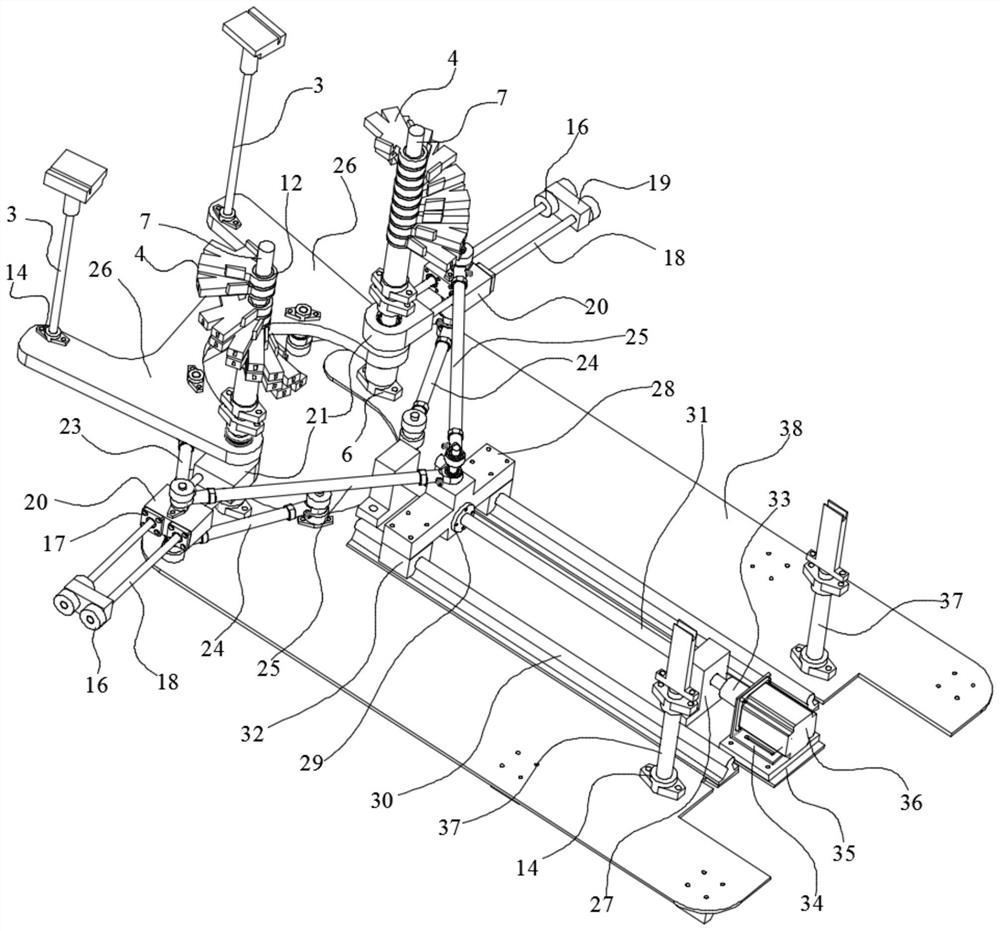

[0035] The present invention is illustrated below in conjunction with the accompanying drawings.

[0036] Such as Figure 1 to Figure 10 As shown, a harvesting trolley of an adaptive vibrating harvester includes a walking trolley II and an umbrella surface harvesting mechanism and a fruit box 9 arranged on the walking trolley II. The umbrella surface harvesting mechanism includes two half-width umbrella surface mechanisms I The structure of the two half-width canopy mechanisms I is the same as that of the canopy opening and closing mechanism III, both of which include the canopy shaft 7 and the canopy pole group composed of a plurality of canopy poles 1, and the canopy shaft 7 is fixedly installed on the walking trolley On II, the inner ends of a plurality of umbrella ribs 1 are sequentially set on the umbrella shaft 7, among which the bottommost umbrella rib 1 is relatively fixedly connected with the umbrella shaft 7, and the remaining umbrella ribs 1 are sequentially sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com