Dispensing head for LED solid crystal and dispensing method of LED solid crystal

A technology of dispensing head and die-bonding, applied in the field of semiconductor lighting, can solve the problems of short-circuit welding of LED chips, poor die-bonding, and LED chip pressing offset, etc., to achieve high reliability, good efficiency, and avoid chip overflow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

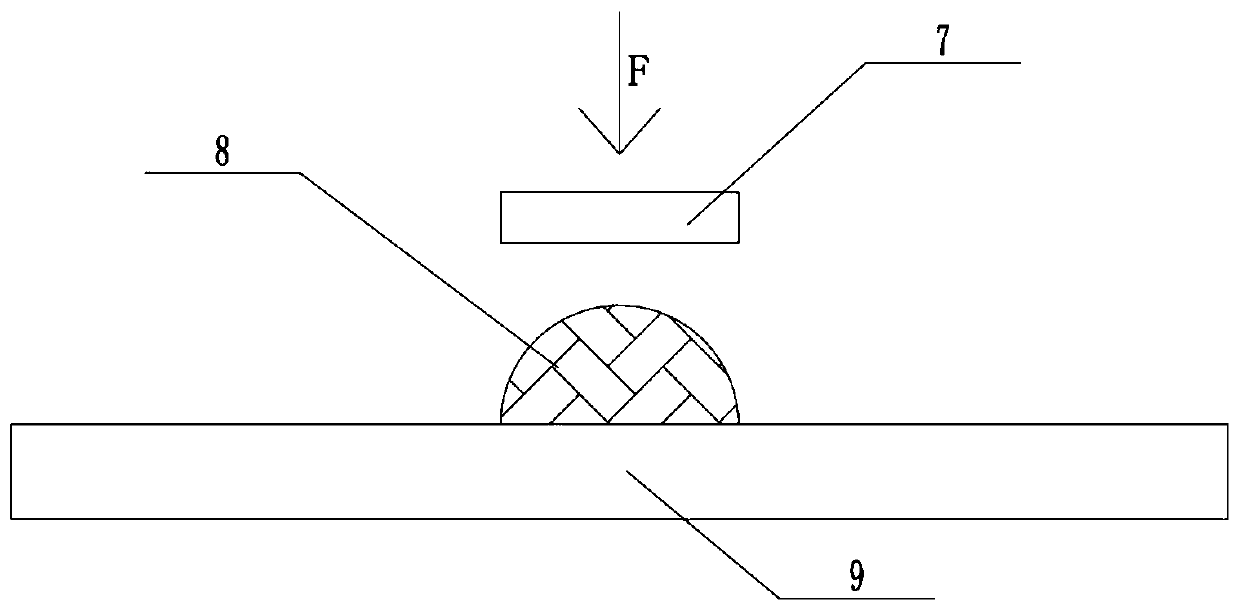

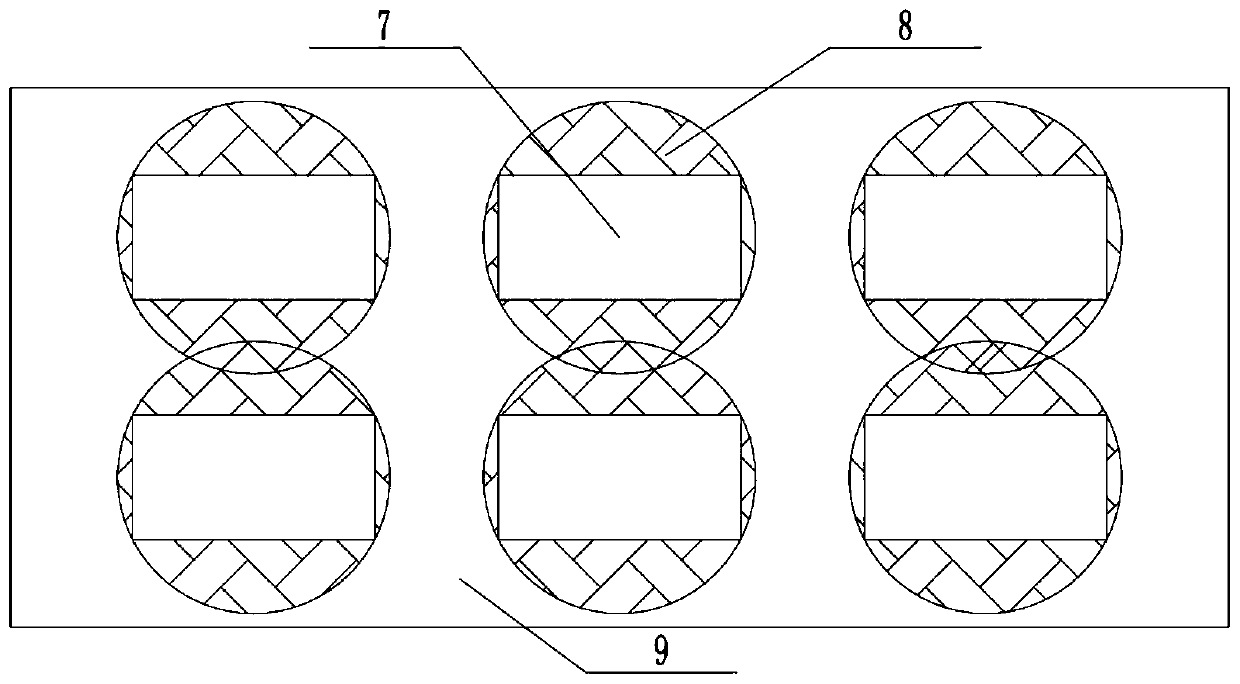

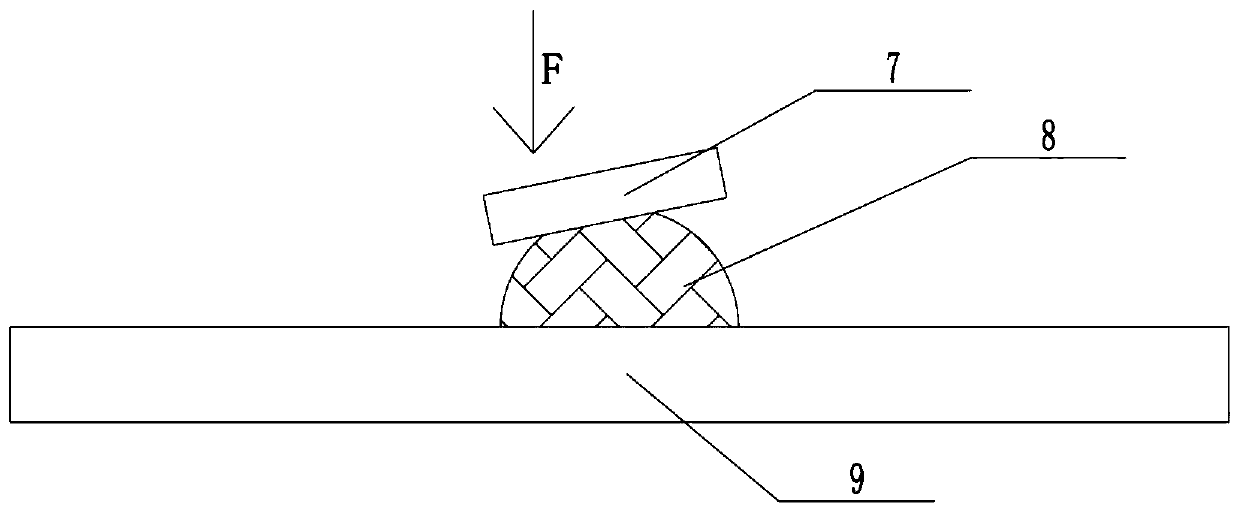

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] A kind of dispensing head for LED solid crystal of the embodiment of the present invention is as Figure 4-5 As shown, it includes a pneumatic mechanism 1 and a glue supply mechanism. The glue supply mechanism is located below the pneumatic mechanism 1. The pneumatic mechanism 1 drives the glue supply mechanism. The glue supply mechanism includes two mirror-imaged glue supply mechanisms. structure, the glue supply structure is fixed under the pneumatic mechanism 1, the glue supply structure includes a connecting rod 2, a glue supply hose 3 and an extruder, and the glue supply hose 3 is fixed on the Below the pneumatic mechanism 1, the shape of the rubber supply hose 3 is L-like, the extruder is arranged at the lower end of the rubber supply hose 3, and the upper end of the rubber supply hose 3 is connected to the glue supply device, Two mirrored extruders are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com