Battery cell hot pressing equipment

A technology for battery cells and hot-pressing equipment, applied in battery electrodes, metal processing equipment, electrolyte battery manufacturing, etc. Good pass rate, good thickness consistency, guaranteeing the effect of rolling pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. It should be noted that, if there is no conflict, the embodiments of the present invention and various features in the embodiments can be combined with each other, and all are within the protection scope of the present invention.

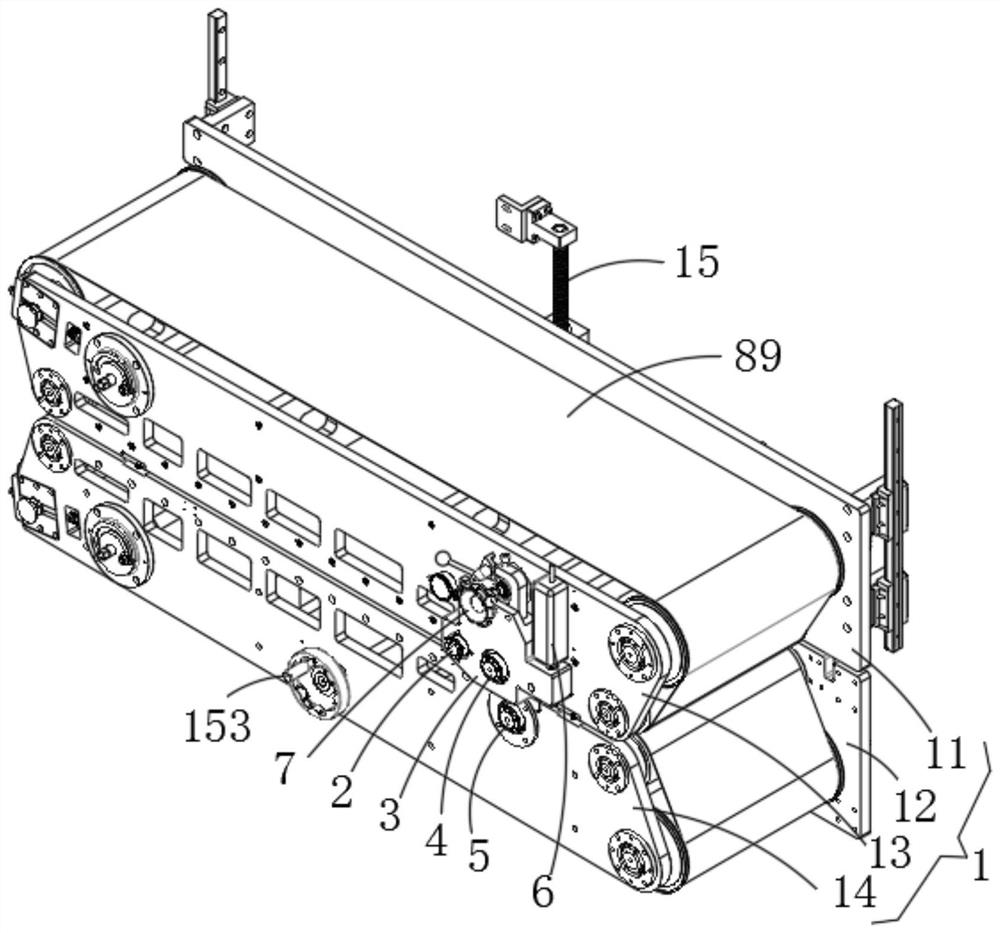

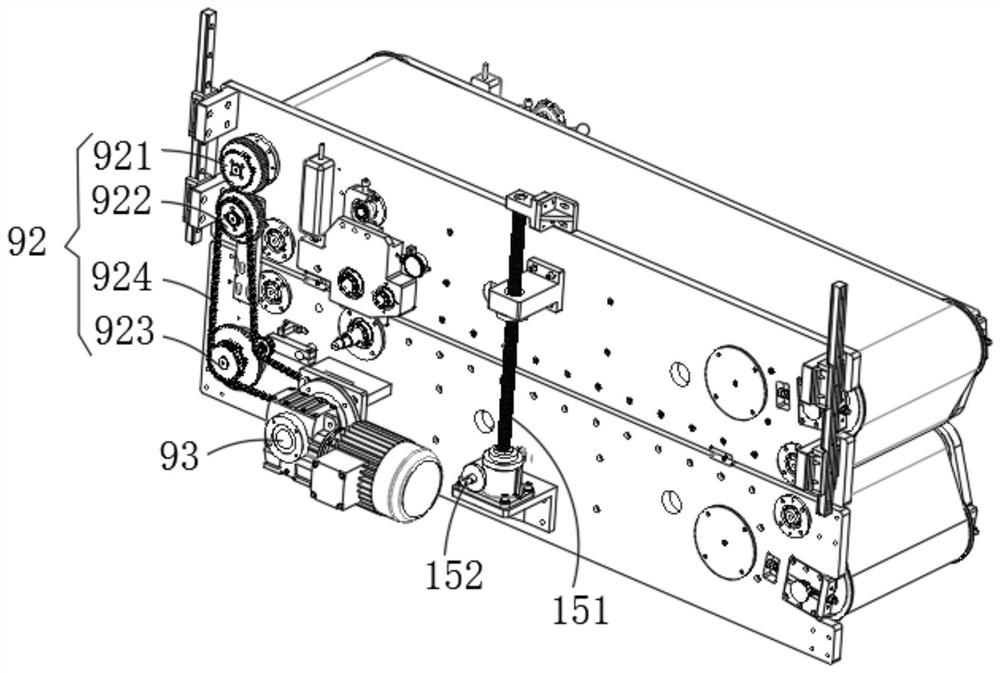

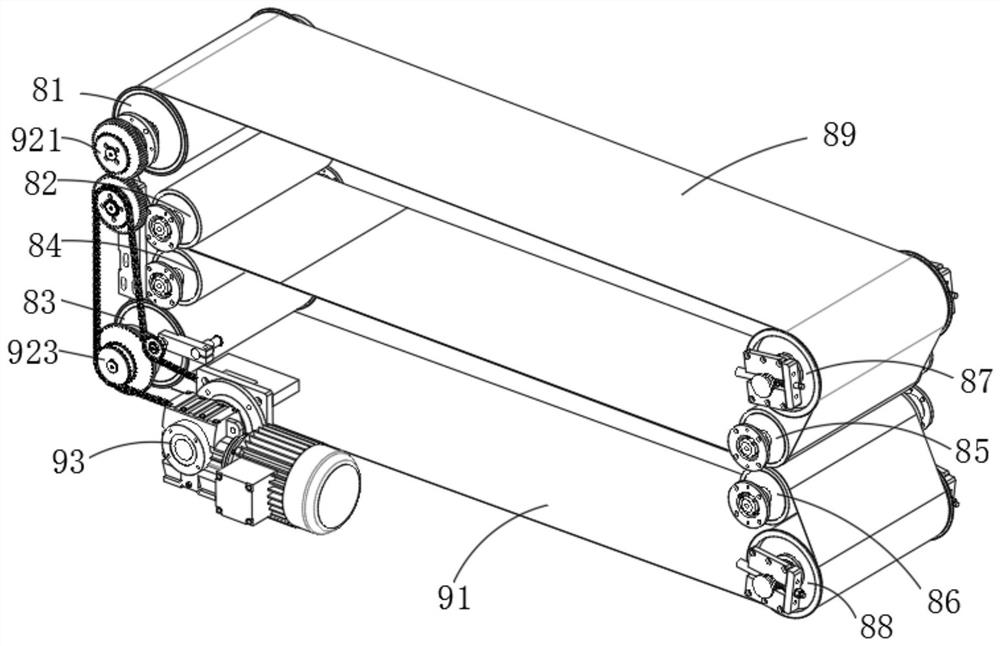

[0021] see Figure 1 to Figure 4 , the invention discloses a battery cell hot pressing equipment, which includes a support mechanism 1, a rotating shaft 2, a mounting block 3, a first pressing roller 4, a second pressing roller 5, a pressure detection device 6 and a positioning device 7. The support mechanism 1 comprises a first support plate 11, a second support plate 12, a third support plate 13, a fourth support plate 14 and a screw lifter 15, the third support plate 13 and the first support plate 11 are located opposite to each other, the fourth support plate 14 is located opposite to the second support plate 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com