Efficient dental denture production centrifugal casting machine

A centrifugal casting machine, dental technology, applied in the direction of dentures, etc., can solve the problems of not being able to cast multiple dentures at the same time, only one denture can be cast at a time, and can not meet the market demand, so as to shorten the cooling time, increase the number of efficiency, The effect of working convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

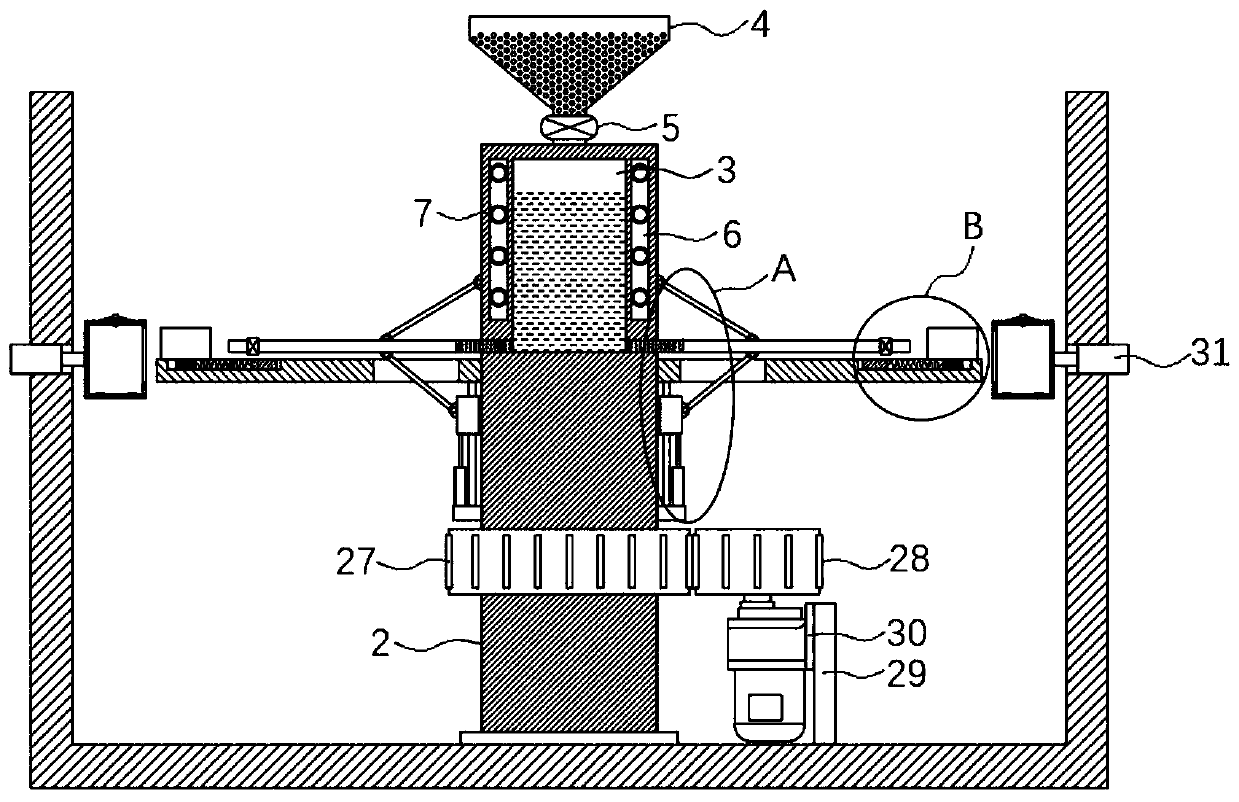

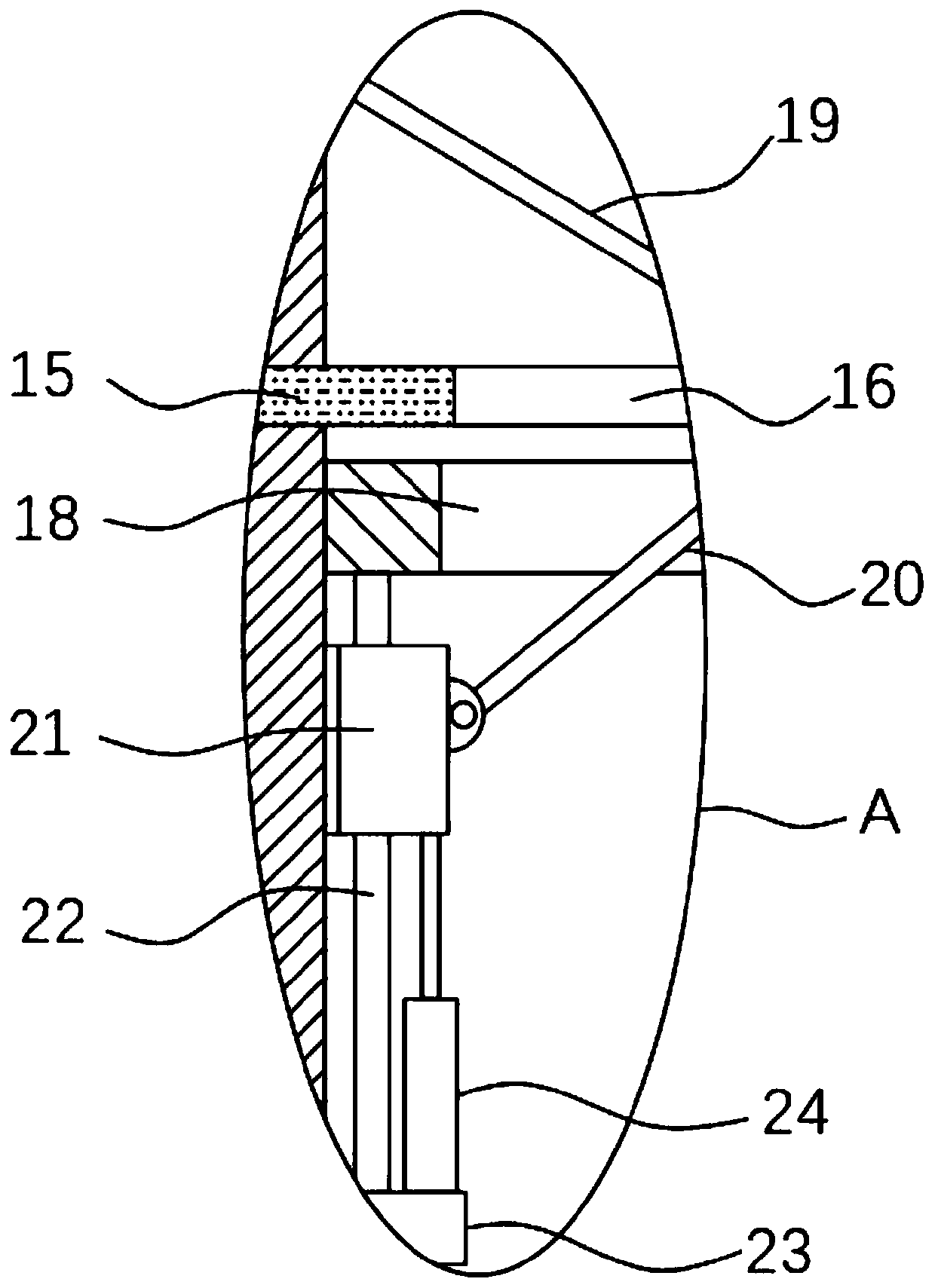

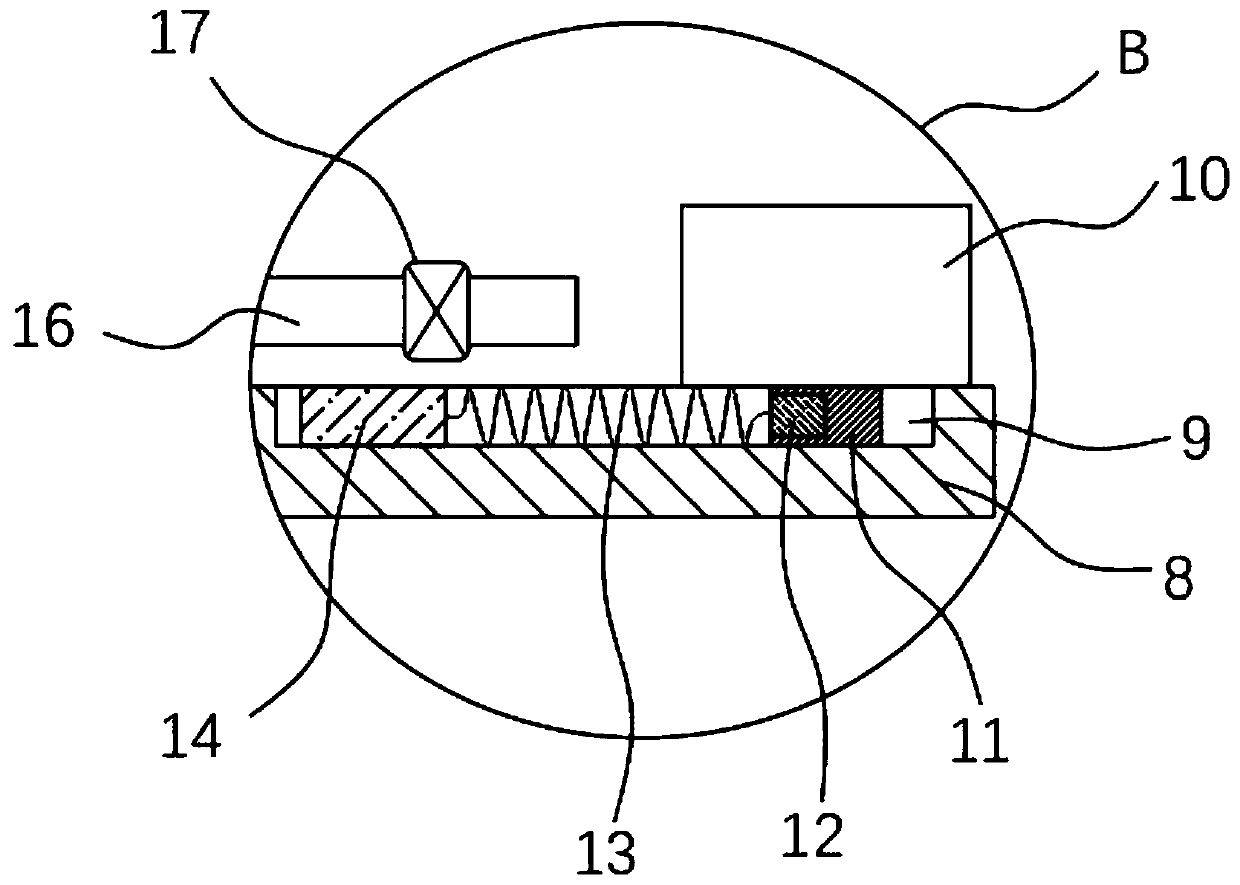

[0029] refer to Figure 1-6 , a high-efficiency centrifugal casting machine for dental denture production, including a protective cylinder 1 with an opening on the upper side to prevent injuries to the staff due to the action of centrifugal force, and a flat surface is used at the axis of the inner bottom wall of the protective cylinder 1 The bearing is rotatably connected with a rotating cylinder 2, and the plane bearing has high load capacity. The lower end of the rotating cylinder 2 is provided with a drive mechanism, which includes a motor mount 29 fixedly installed on the inner bottom wall of the protective cylinder 1, and the motor mount One side side wall of 29 is fixedly installed with speed-regulating motor 30, and the driving end of speed-regulating motor 30 is interference-fitted with driving gear 28, and the interference fit on rotating cylinder 2 is equipped with driven gear 27 meshing with driving gear 28, through The speed governor sets the rotating speed of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com