Buoyant device for amphibious operation drilling platform

A technology of drilling platform and buoyancy device, which is applied in the fields of petroleum engineering drilling and basic engineering drilling to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

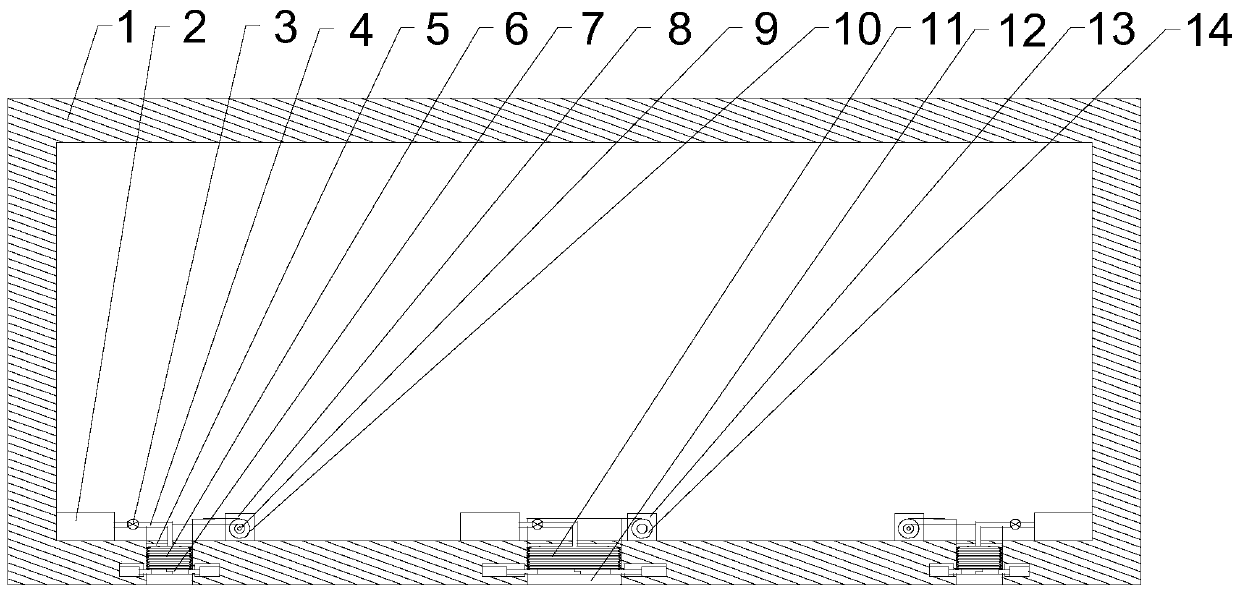

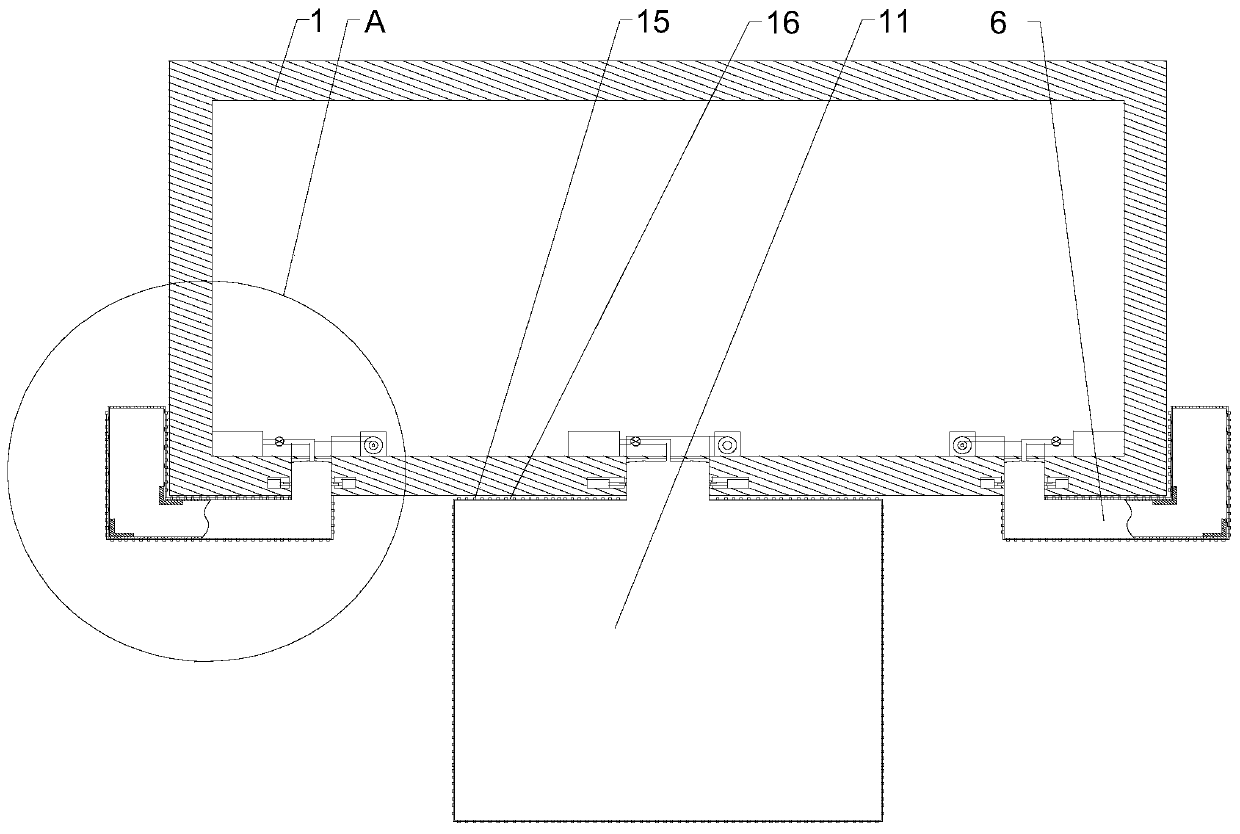

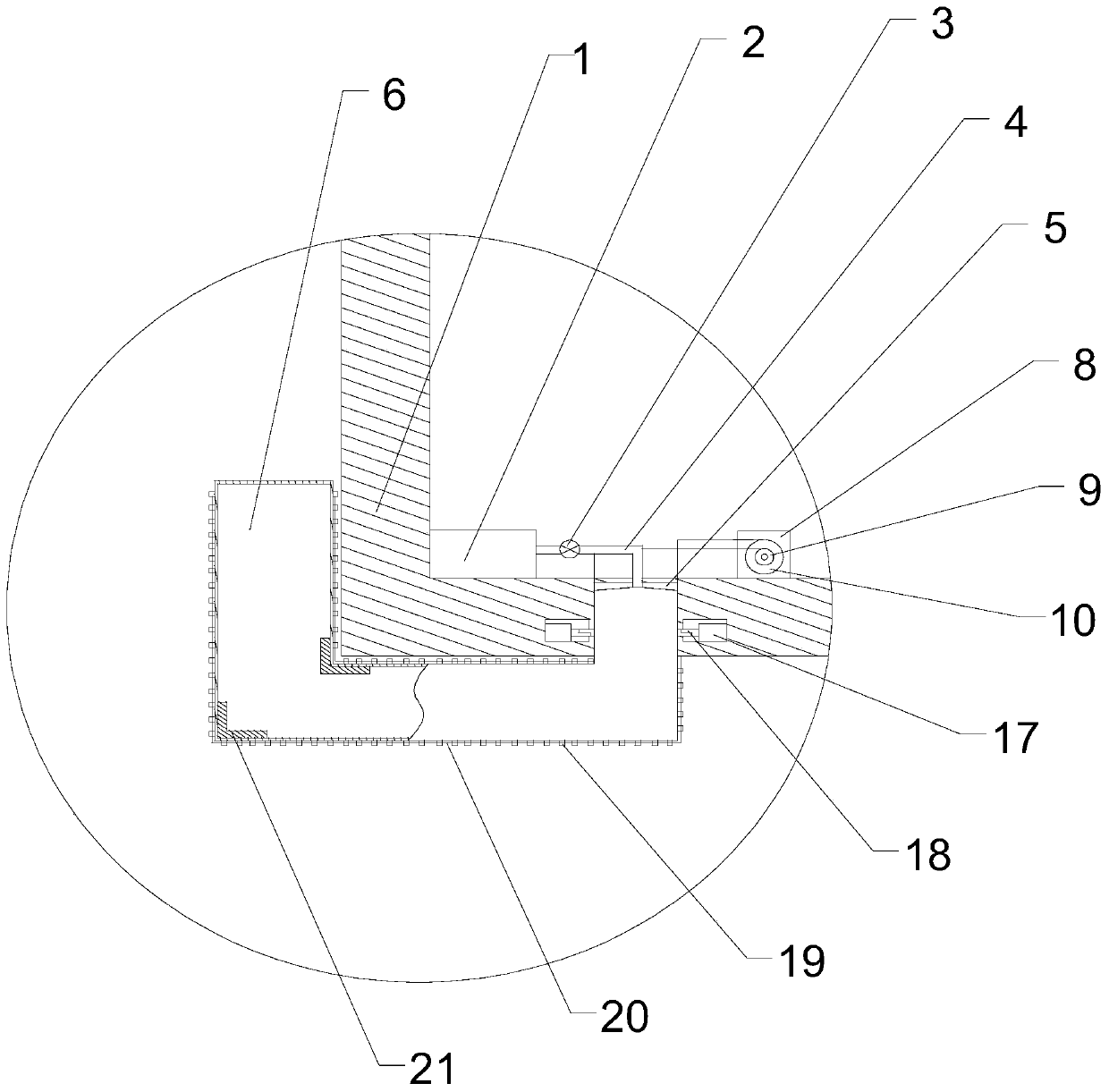

[0024] Such as Figure 1~3 As shown, this embodiment includes two airbags I6 and one airbag II11, a rectangular groove I5 is respectively opened on both sides of the bottom of the base 1, and a rectangular groove II12 is opened in the middle of the bottom surface of the base 1, and the airbag I6 is in the form of Folded and placed in the rectangular groove Ⅰ5, the airbag II11 is folded and placed in the rectangular groove II12, there are three inflation mechanisms inside the base 1, the inflation mechanism includes the fan 2, the booster pump 3 and the air pipe 4, the booster The pump 3 is arranged on the trachea 4, and one end of the trachea 4 communicates with the air outlet of the fan 2, and the other end of the trachea 4 passes through the base 1 and then communicates with the airbag I6; the airbag I6 is U-shaped after inflation and expansion, and the airbag I6 The inner vertical section of the airbag I6 is placed in the rectangular groove I5, the distance between the side...

Embodiment 2

[0030] Such as Figure 1~3 As shown, this embodiment is based on Embodiment 1. When the initial state or the drilling process is completed, the airbag I6 and the airbag II11 will be folded in the rectangular groove I5 and the rectangular groove II12 respectively. When the airbag II11 is used, the airbag I6 or the airbag II11 cannot be completely accommodated in the groove only by the draft of the fan 2. For this, the applicant has provided a plurality of hanging rings I19 on the outer surface of the airbag I6, and on the outer surface of the airbag II11 There are multiple hanging rings II15 on the top, and because the airbag I6 is inflated and expanded, it is U-shaped, and the multiple hanging rings I19 located on the inner surface of the airbag I6 are connected in series with the winding roller in the base 1 through a traction rope I20 The multiple hanging rings I19 on the outer surface of the airbag I6 are connected in series with the winding roller II10 in the base 1 throug...

Embodiment 3

[0033] Such as Figure 1~3 As shown, this embodiment is based on Embodiment 2, because the drilling platform often switches between the land environment and the water environment, the rectangular groove I5 and the rectangular groove II12 may have wading situations, and long-term immersion will Corrosion of the airbag I6 or the airbag II11, adhesion of microorganisms, etc., can easily reduce the service life of the airbag. For this, the applicant has two opposite sides on the inner side walls of the rectangular groove I5 and the rectangular groove II12. The provided cavity is provided with a driving cylinder 17, a rectangular through hole communicating with the rectangular groove I5 or rectangular groove II12 is opened on the cavity wall, and a sealing plate 7 is provided on the output end of the driving cylinder 17, After the airbag is recovered, the driving cylinder 17 can be activated until the opposite end surfaces of the two sealing plates 7 contact each other, so as to cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com