A kind of processing technology of corrosion-resistant aluminum-magnesium alloy

A technology of aluminum-magnesium alloy and processing technology, which is applied in the direction of metal material coating technology and coating, can solve the problems that the strength and corrosion resistance cannot meet our needs, inconvenience, and the service life of aluminum-magnesium alloys is reduced, so as to improve Anti-corrosion performance, avoiding agglomeration, enhancing the effect of strength and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] First prepare raw materials, weigh aluminum ingots, magnesium ingots, aluminum-chromium master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, electrolytic copper, zinc ingots, aluminum-manganese master alloys, aluminum-titanium master alloys, aluminum-lanthanum master alloys and Al-beryllium master alloy, spare; weigh graphene oxide in proportion, grind it in a ball mill for 20 minutes to obtain graphene oxide powder; Amide, for subsequent use; take hexadecyltrimethoxysilane and dodecyltrimethoxysilane in proportion, and mix them uniformly to obtain modifier, for subsequent use;

[0058] Then prepare the alloy matrix, take the aluminum ingot and place it in the furnace, heat up to 660°C, then add graphene oxide powder, stir for 20 minutes, then add aluminum-silicon master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy, keep warm for 20 minutes, and then heat up To 740°C, add magnesium ingots, aluminum-chromium master alloys,...

Embodiment 2

[0063]First prepare raw materials, weigh aluminum ingots, magnesium ingots, aluminum-chromium master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, electrolytic copper, zinc ingots, aluminum-manganese master alloys, aluminum-titanium master alloys, aluminum-lanthanum master alloys and Al-beryllium master alloy, spare; weigh graphene oxide in proportion, grind it in a ball mill for 25 minutes, and obtain graphene oxide powder; Amide, for subsequent use; take hexadecyltrimethoxysilane and dodecyltrimethoxysilane in proportion, and mix them uniformly to obtain modifier, for subsequent use;

[0064] Then prepare the alloy matrix, take the aluminum ingot and put it in the furnace, heat up to 670°C, then add graphene oxide powder, stir for 23 minutes, then add aluminum-silicon master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy, keep it warm for 25 minutes, and then raise the temperature To 750°C, add magnesium ingots, aluminum-chromiu...

Embodiment 3

[0069] First prepare raw materials, weigh aluminum ingots, magnesium ingots, aluminum-chromium master alloys, aluminum-iron master alloys, aluminum-silicon master alloys, electrolytic copper, zinc ingots, aluminum-manganese master alloys, aluminum-titanium master alloys, aluminum-lanthanum master alloys and Al-beryllium master alloy, spare; weigh graphene oxide in proportion, grind it in a ball mill for 30 minutes, and obtain graphene oxide powder; Amide, for subsequent use; take hexadecyltrimethoxysilane and dodecyltrimethoxysilane in proportion, and mix them uniformly to obtain modifier, for subsequent use;

[0070] Then prepare the alloy matrix, take the aluminum ingot and put it in the furnace, heat up to 680°C, then add graphene oxide powder, stir for 25 minutes, then add aluminum-silicon master alloy, aluminum-manganese master alloy, aluminum-titanium master alloy, keep warm for 30 minutes, and then heat up to 760°C, add magnesium ingots, aluminum-chromium master alloys,...

PUM

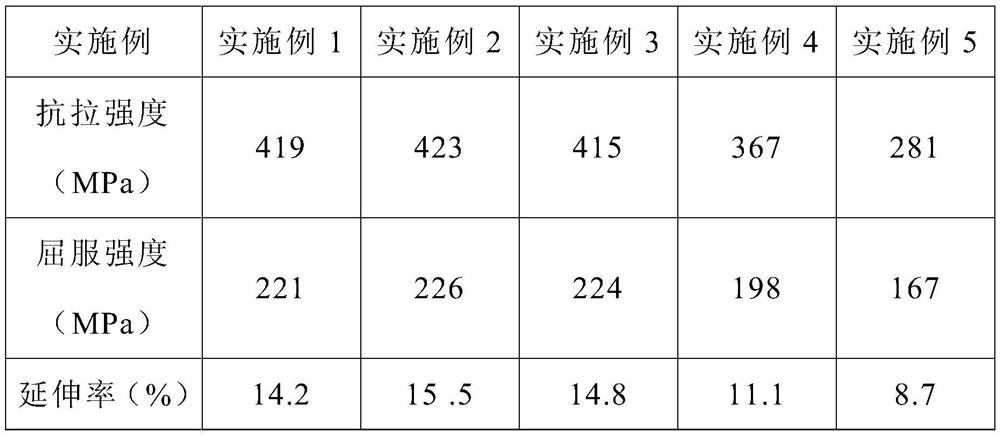

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com