A detachable prefabricated modular shear wall based on section steel connection and its assembly method

A shear wall and prefabricated mold technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of poor popularity, complicated operation, labor and time-consuming, etc., and achieve the effect of easier quality inspection, saving construction costs, and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

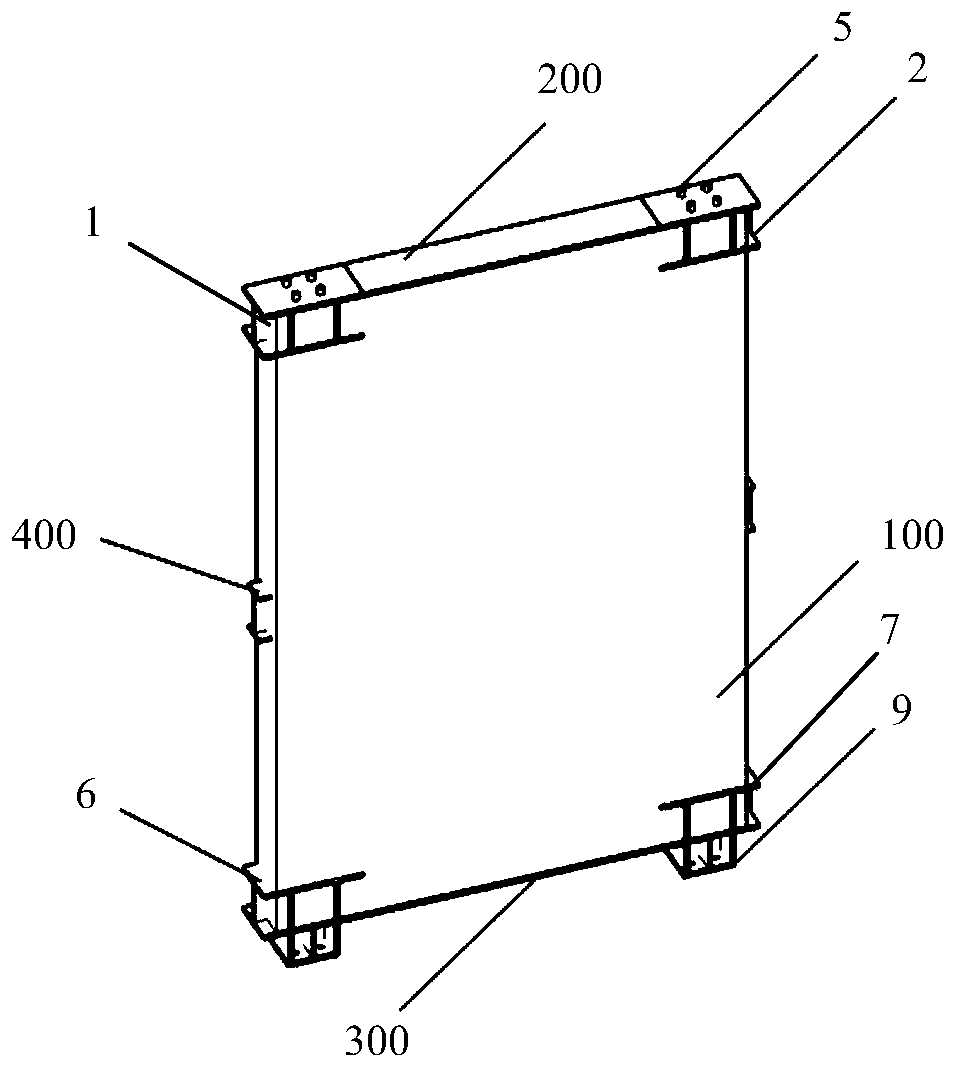

[0032] Depend on figure 1 As shown, the present invention provides a detachable prefabricated modular shear wall based on section steel connection (hereinafter referred to as: wall), which is stronger than cast-in-place prefabricated shear wall in terms of strength, and more functional than cast-in-place structure. Meet the strong node design requirements. The use of section steel as the connection method of prefabricated components can provide more accurate positioning than traditional wet connections, faster installation, easier quality inspection, and construction cost savings.

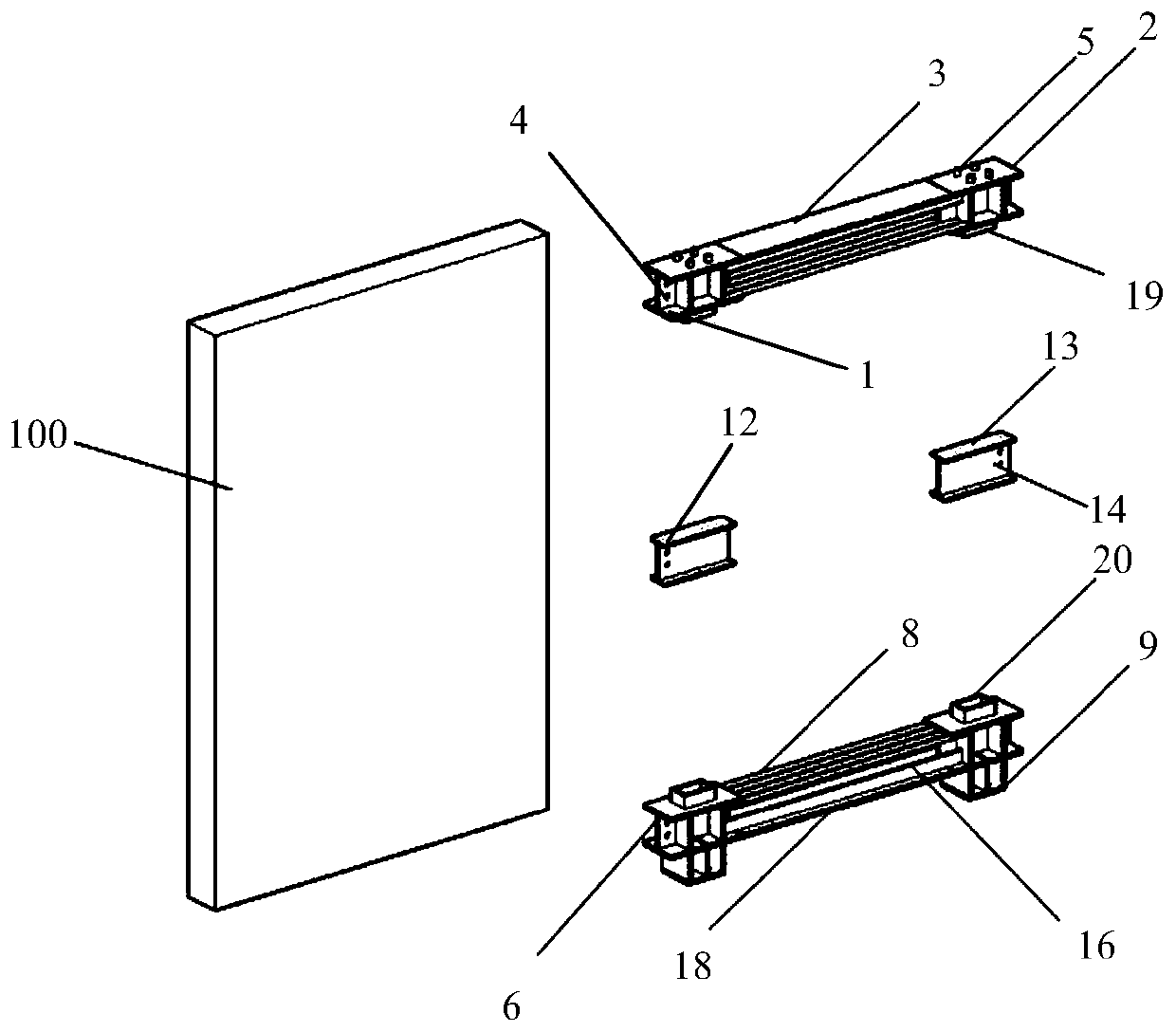

[0033] Such as figure 2 As shown, the present invention includes a reinforced concrete wall 100, an upper steel connector 200, a lower steel connector 300 and an intermediate reinforced connector 400, an upper steel connector 200, a lower steel connector 300 and an intermediate reinforced connector 400 are pre-embedded at the top, bottom and middle of the reinforced concrete wall 100 respectivel...

Embodiment 2

[0041] On the basis of Embodiment 1, the present invention is also provided with a strip-shaped steel plate, which is used to realize the fixing of the vertical reinforcement in the wall. as follows:

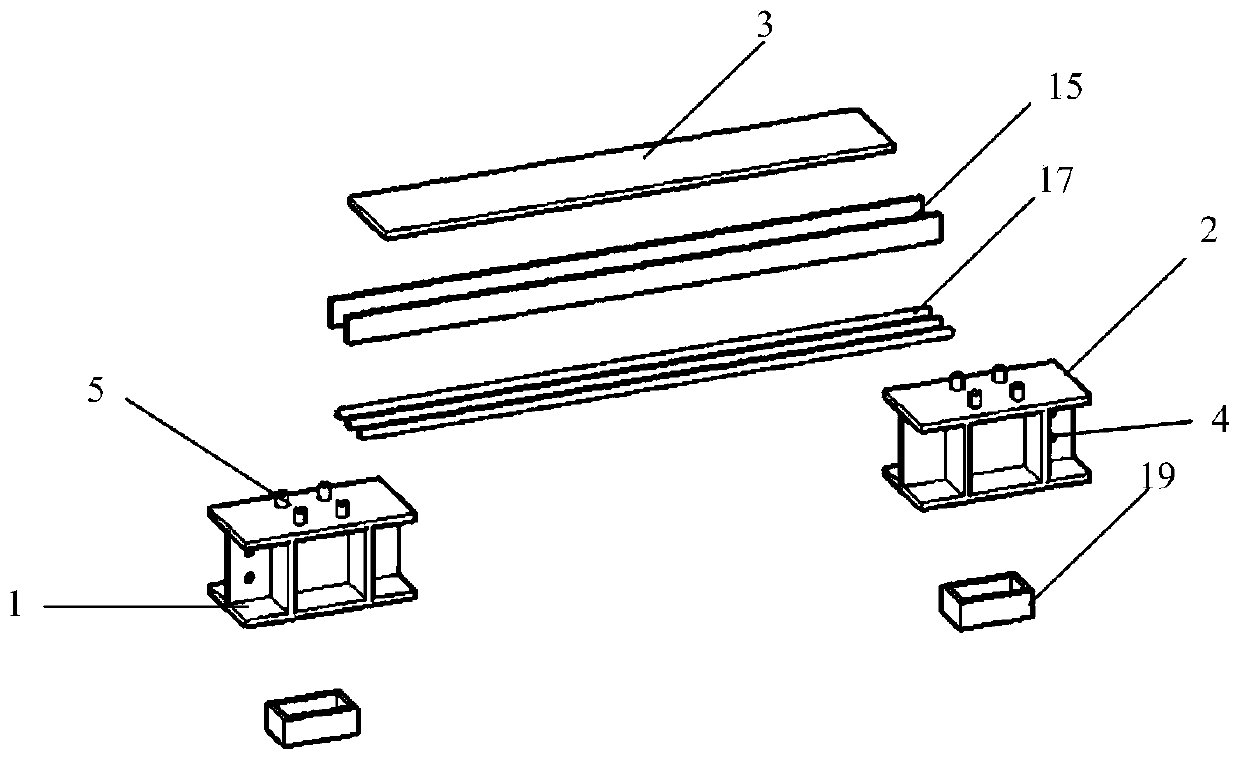

[0042] Such as image 3 As shown, the upper steel connector 200 also includes an upper bar-shaped steel plate 15, and the upper bar-shaped steel plate 15 appears in pairs and is welded and fixed between the first I-shaped steel plate 1, the second I-shaped steel plate 2 and the bottom of the upper steel plate 3 , the bottom of the upper strip steel plate 15 is welded to the end of the vertical reinforcement in the reinforced concrete wall 100 .

[0043] Similarly, such as Figure 4 As shown, the lower steel connector 300 also includes a lower bar-shaped steel plate 16, the lower bar-shaped steel plate 16 appears in pairs and is welded and fixed between the third I-shaped steel plate 6, the fourth I-shaped steel plate 7 and the bottom of the lower steel plate 8 , the top of th...

Embodiment 3

[0046] On the basis of Embodiment 2, the present invention is also provided with a plurality of side-by-side steel bars, and the steel bars replace the steel plate flanges, which can strengthen the connection between the built-in steel connector and the reinforced concrete wall. as follows:

[0047] Such as image 3 As shown, the upper steel connector 200 also includes a plurality of upper steel bars 17, and each upper steel bar 17 is connected with the first I-shaped steel plate 1 and the second I-shaped steel plate 2 after being arranged side by side. bottom.

[0048] Similarly, such as Figure 4 As shown, the lower steel connector 300 also includes a plurality of lower steel bars 18, and each lower steel bar 18 is connected with the third I-shaped steel plate 6 and the fourth I-shaped steel plate 7 after being arranged side by side, and each lower steel bar 18 is located at the bottom of the lower bar-shaped steel plate 16. bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com