Online monitoring system and method of micro-leakage of low-pressure gas pipeline

A gas pipeline and monitoring system technology, applied in pipeline systems, measuring devices, gas/liquid distribution and storage, etc., can solve the problems of difficulty in small leaks, detection and judgment of leak locations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

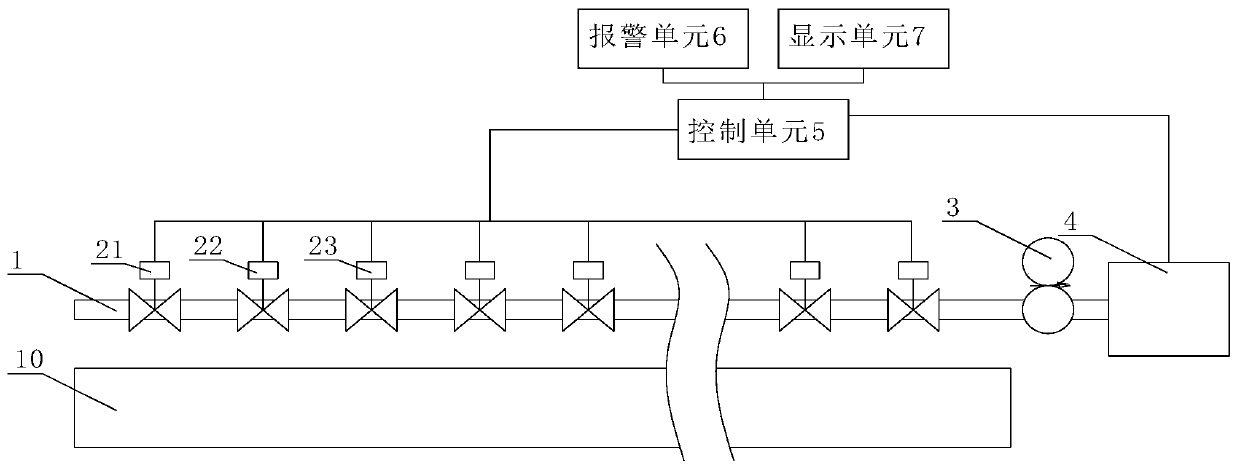

[0031] Such as figure 1 As shown, an on-line monitoring system for micro-leakage of low-pressure gas pipelines includes an air suction pipeline 1 for absorbing gas in the gas pipeline 10 and a control unit 5. An air suction pump 3 is arranged at the end of the air suction pipeline 1. 1. A concentration detector 4 is arranged on the end surface close to the suction pump 3; multiple groups of suction holes are sequentially arranged in the length direction of the suction pipeline 1, and electric valves are arranged between each adjacent two groups of suction holes. Each electric valve is used to throttle the suction pipe 1 at the front end of the electric valve, and the electric valve is connected with the control unit 5 . The electric valve can be a solenoid valve.

[0032] In this embodiment, the air suction pipeline 1 is a thin tube arranged above the gas pipeline 10 . There is one suction hole in each group, and it is arranged opposite to the gas pipeline 10 . Since the de...

Embodiment 2

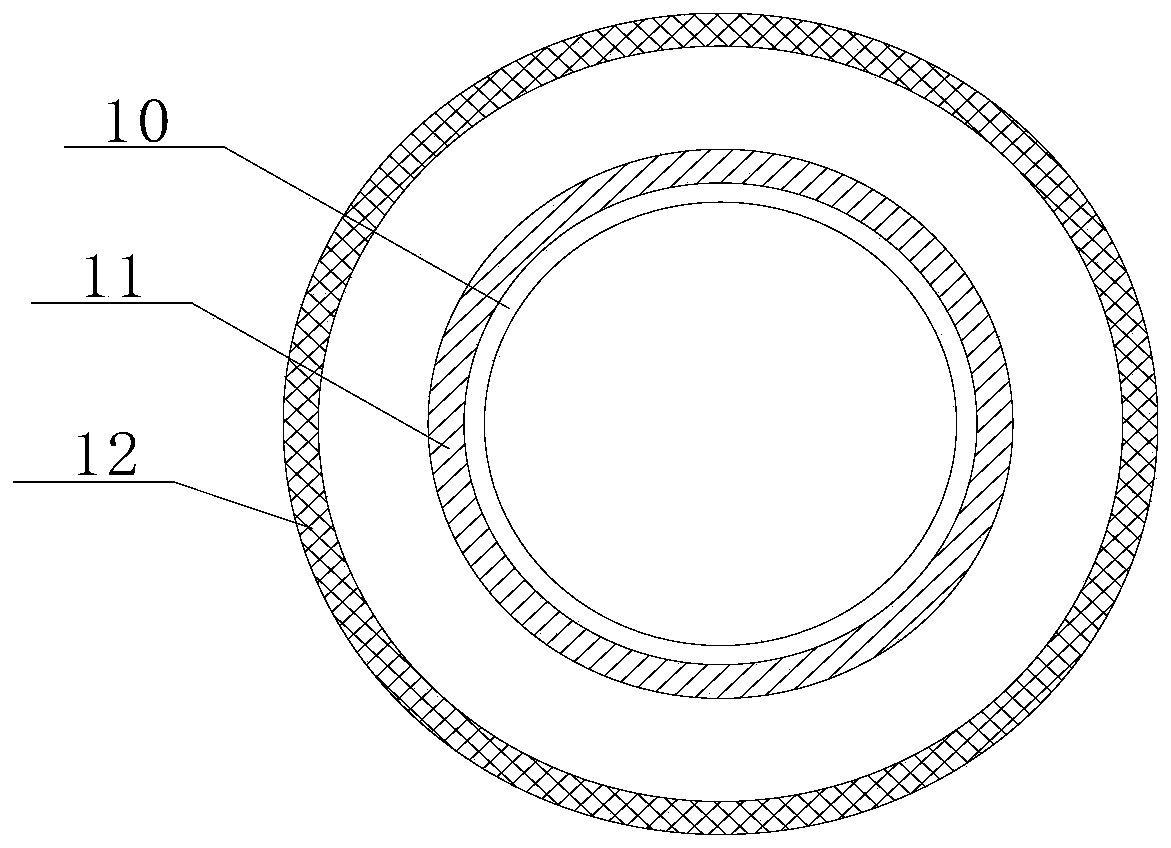

[0036] Such as figure 2 As shown, the difference from Embodiment 1 is that the suction pipe 1 is an annular pipe wrapped on the gas pipe 10, and the annular pipe includes an inner ring 11 that is close to the outer wall of the outer wall of the gas pipe 10, and an inner ring 11 concentric outer ring 12. There are several suction holes in each group, which are arranged in a ring on the inner ring 11 . When the leakage point is located at the unopened air suction hole of the inner ring 11, the suction pipe 1 can also play a role in preventing air leakage. When the leakage point is relatively large, the system can also monitor it.

Embodiment 3

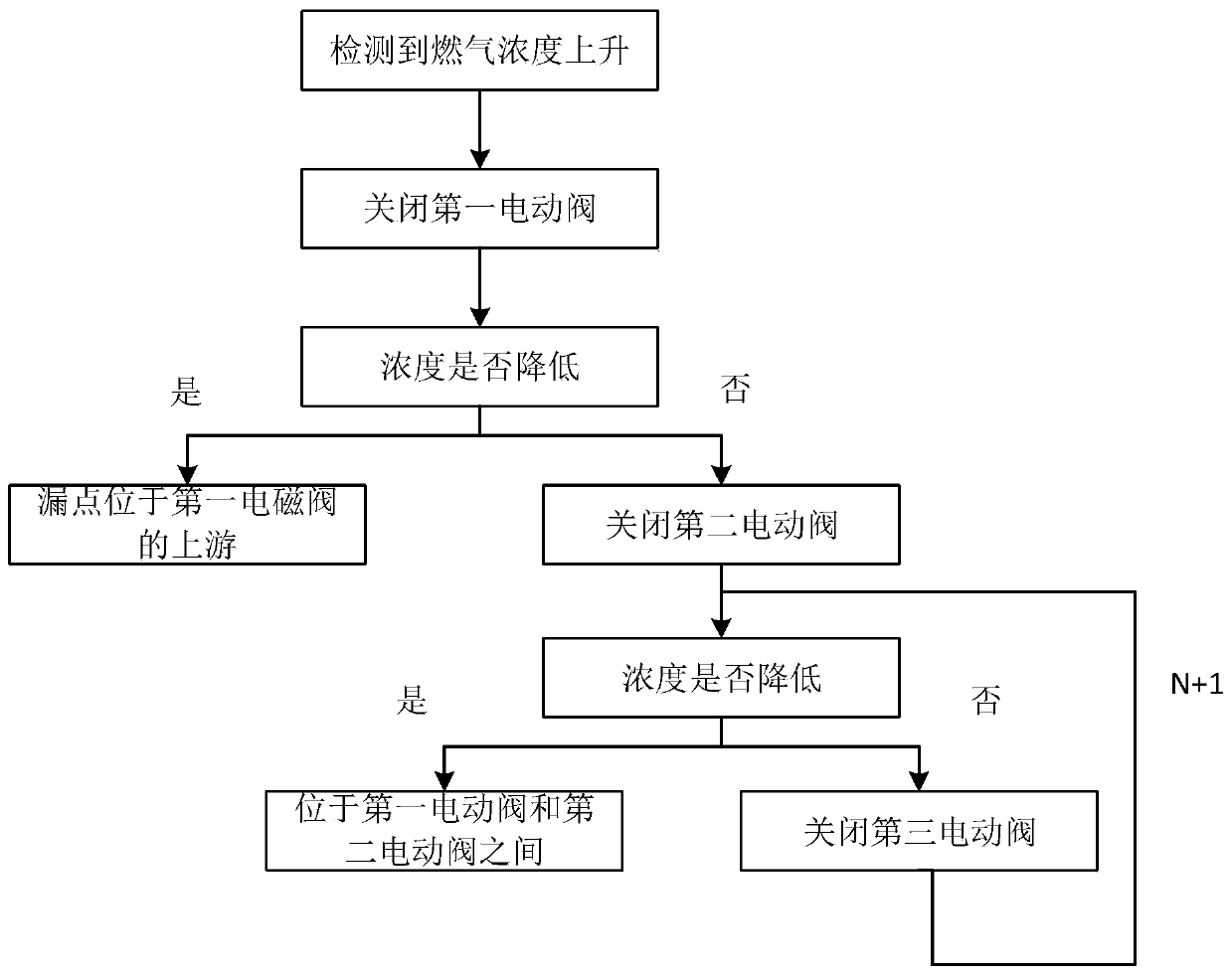

[0038] Such as image 3 As shown, the method of using any one of the low-pressure gas pipeline micro-leakage online monitoring systems in the above two embodiments includes the following steps:

[0039] S1, all electric valves are open, the suction pump 3 works, and the gas is input into the concentration detector 4; the safe concentration value is set in the control unit 5, and a comparison module is arranged in the control unit 5, and the concentration detector 4 will The data is sent to the control unit 5. When the value input by the concentration detector 4 to the control unit 5 is greater than the safe concentration value, the control unit 5 controls the alarm unit 6 to work and automatically enters step S2.

[0040] S2, when the numerical value in the concentration detector 4 rises, the control unit 5 closes the first electric valve 21 farthest away from the concentration detector 4, after setting time, whether the concentration detected by the concentration detector 4 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com