New ultra-high precision electromagnetic electronic balance

An electronic balance and electromagnetic technology, applied in the field of new ultra-high-precision electromagnetic electronic balances, can solve the problems of difficulty in guaranteeing electromagnetic balance sensor coils and magnetic steel, hindering the application of electromagnetic balance sensors, and uneven coil wall thickness, etc. Stability and correctness, easy installation and debugging, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

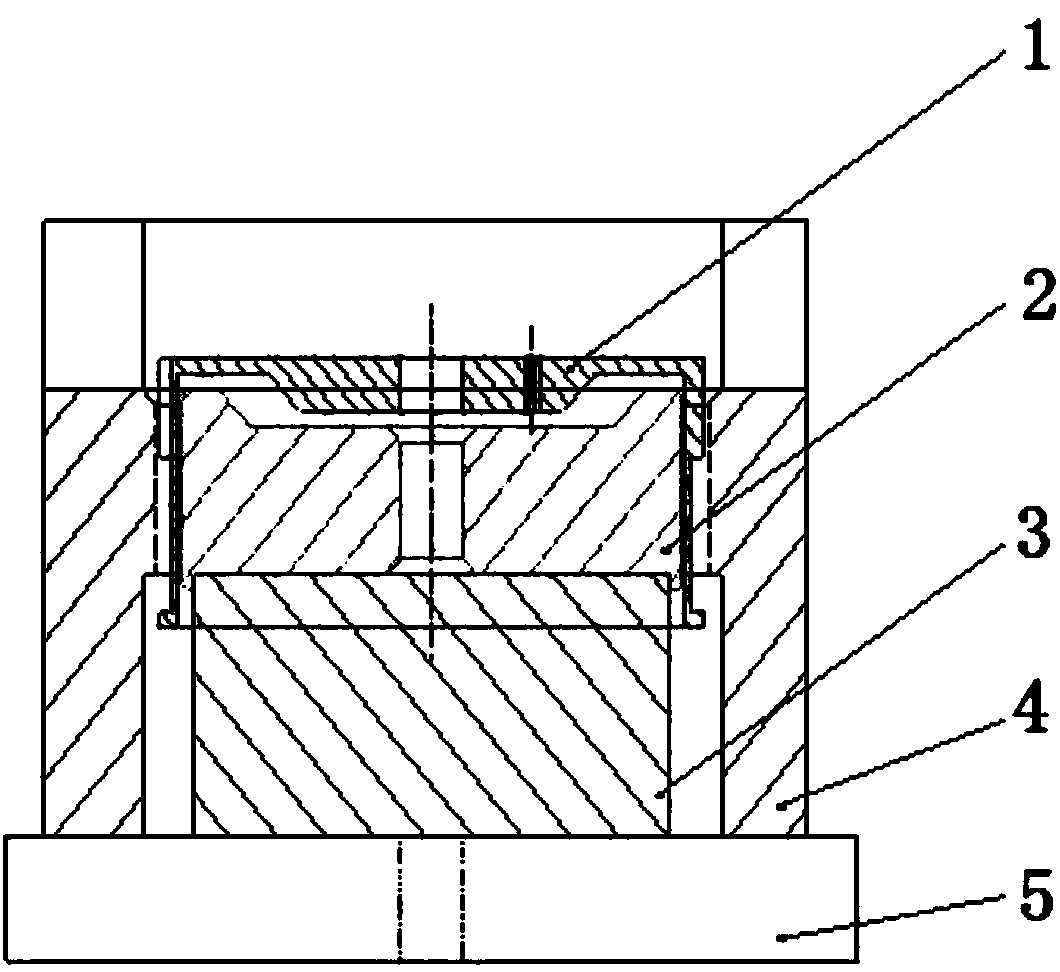

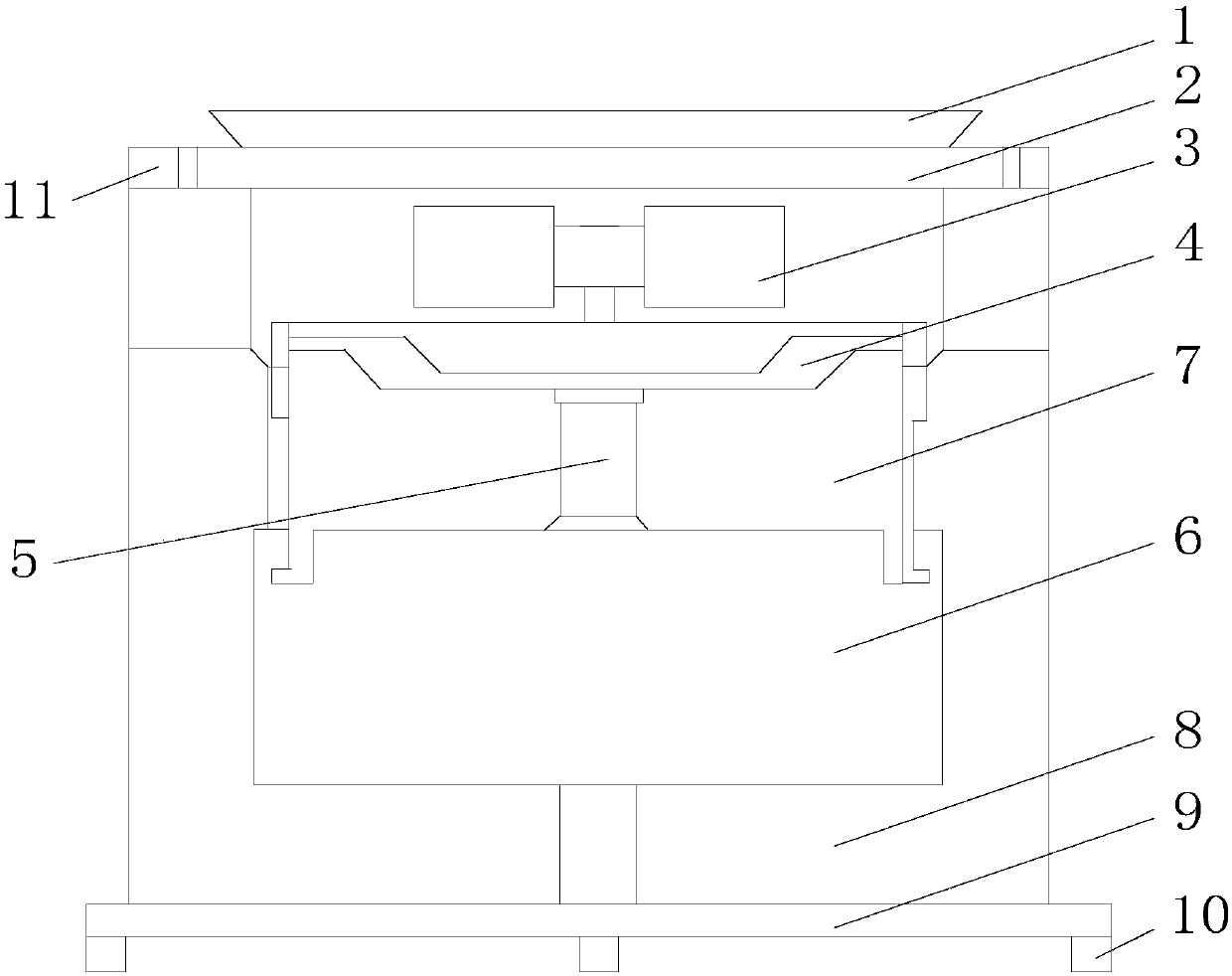

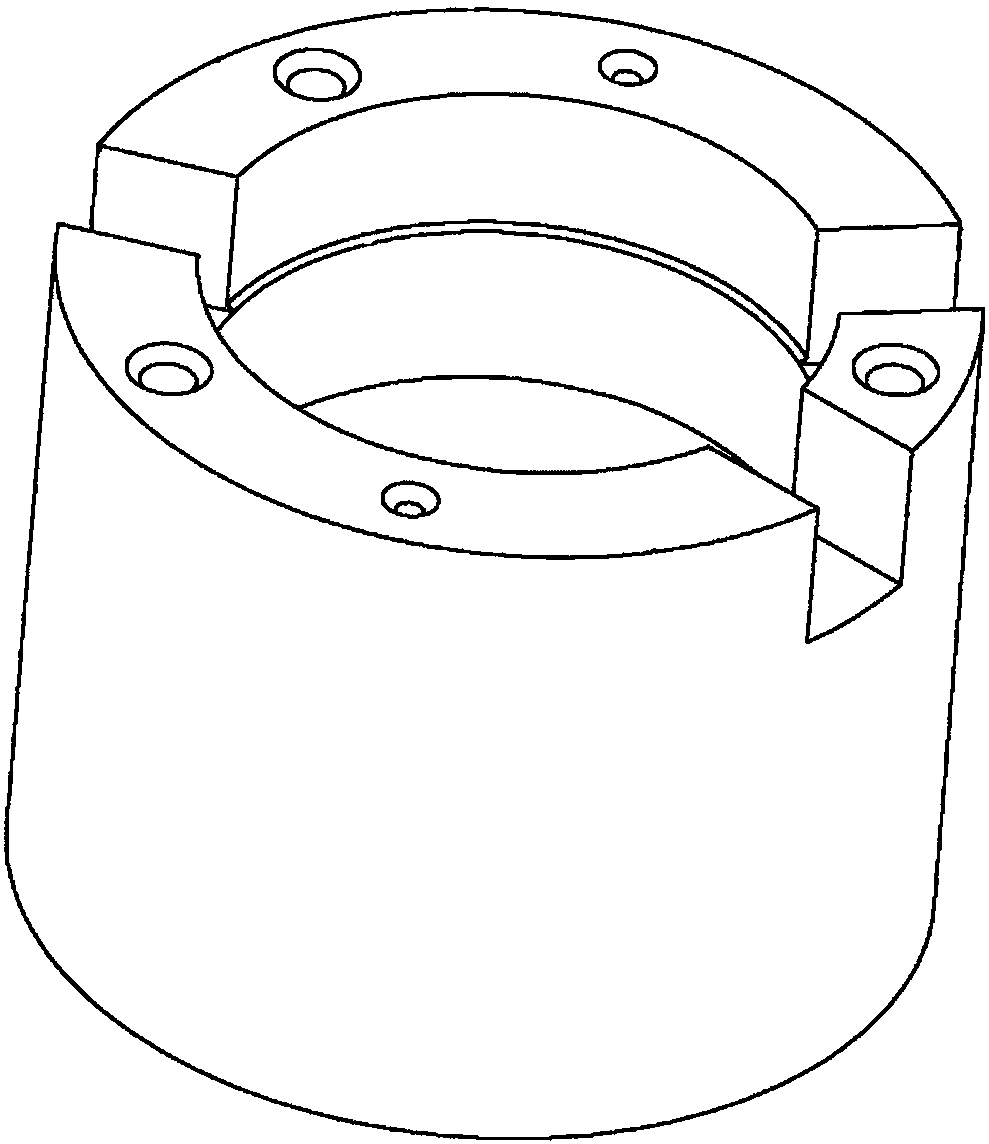

[0021] See figure 2 and image 3 , the present invention has a weighing pan 1 placed on the upper end of the windshield casing; the weighing pan 1 is fixed on the bracket 2; the sensor assembly placed in the windshield casing is installed below the bracket 2; the sensor assembly includes a bracket, a magnetic steel 6. The magnetic pole 7 and the coil 4; the bubble balancer 3 is installed under the bracket 2; the bubble balancer 3 is connected to the magnetic steel 6 installed in the windshield casing through the connecting rod 5; the connecting rod 5 is sleeved with the bottom and The magnetic pole 7 which is in contact with the upper surface of the magnetic steel 6 and the coil 4 whose bottom is in contact with the upper surface of the magnetic pole 7; the outer side of the magnetic steel 6 is covered with a seat cover 8 which is composed of a magnetic steel cover and a magnetic steel base; The accommodating cavity of the magnetic steel has a bottom plate 9 under the seat c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com