Polarization/depolarization current test method for multi-layer oil-paper composite insulation structure

A composite insulation and current test technology, applied in the direction of testing dielectric strength, etc., can solve problems such as long space charge dissipation time and high-frequency interference in data processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

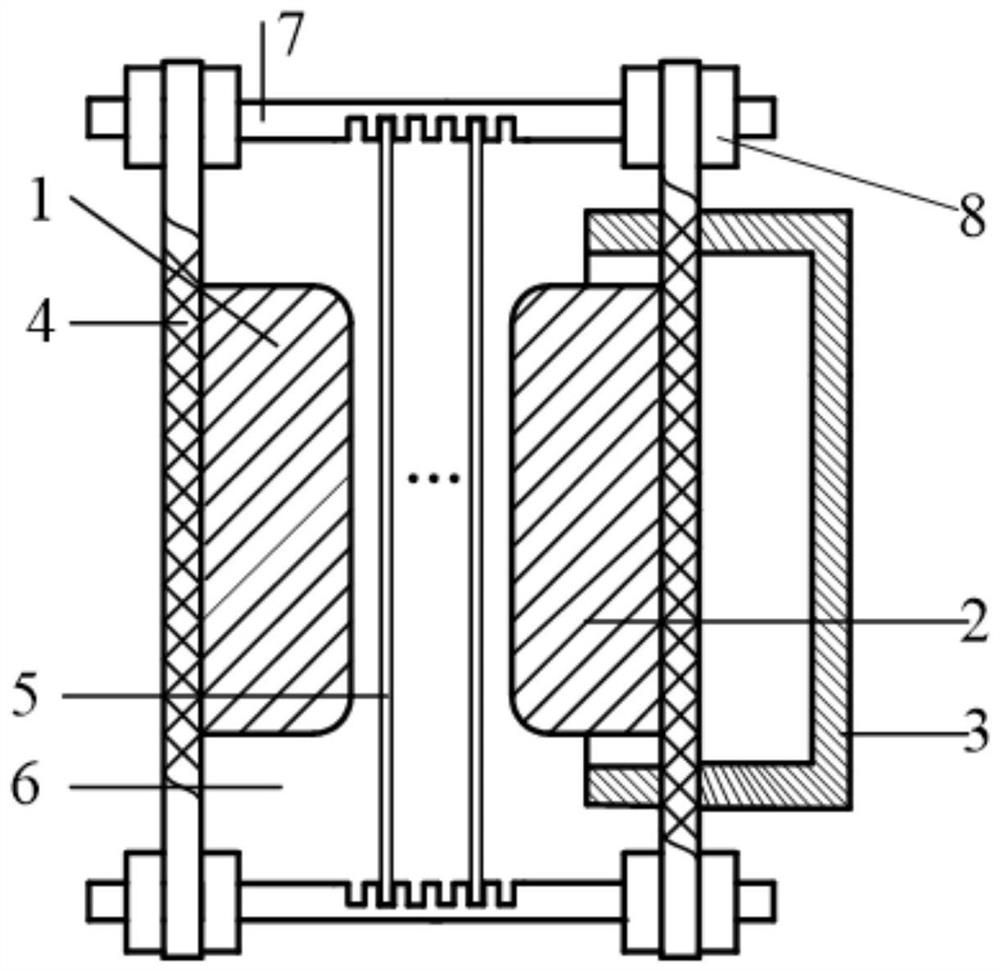

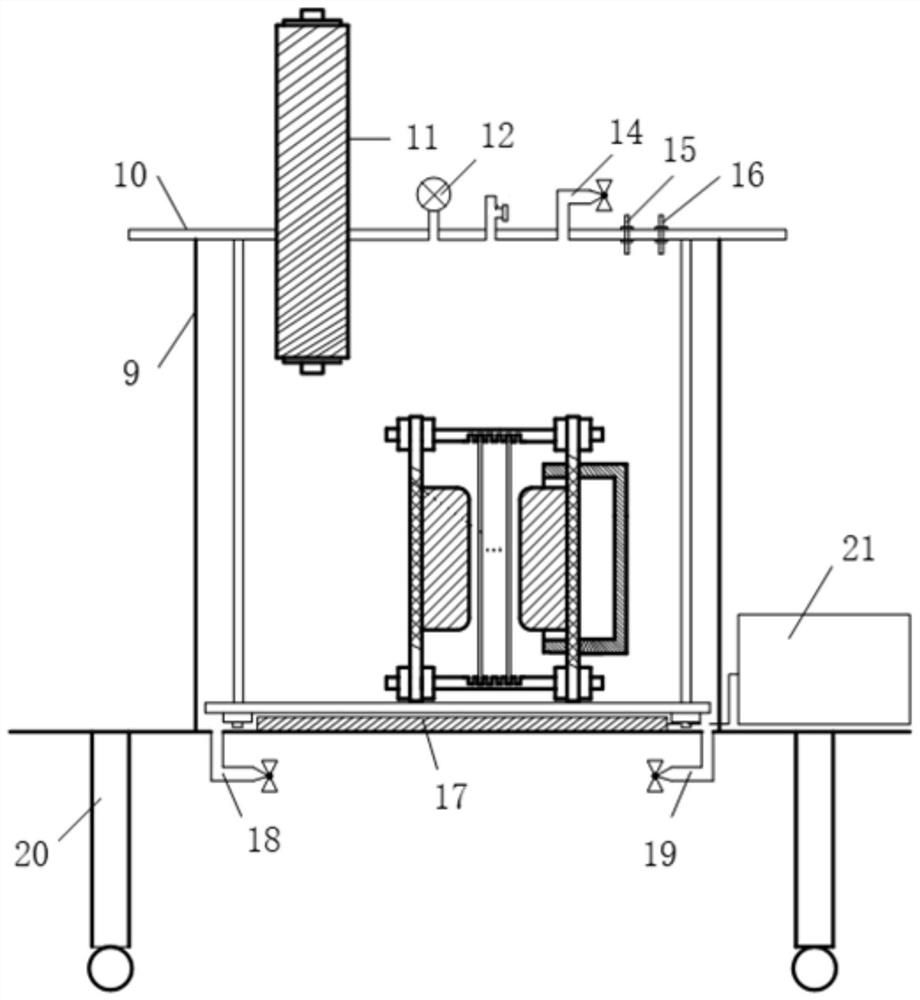

[0025] Specific implementation mode 1: In this implementation mode, the polarization / depolarization current test method of multi-layer oil-paper composite insulation structure under high voltage level is implemented according to the following steps:

[0026] 1. Adjust the distance between the oil gaps of the three-electrode system, insert the oil-soaked cardboard 5 into the notch of the metal support rod 7 of the three-electrode system, and the middle of the high-voltage electrode 1 and the measuring electrode 2 is a multi-layer composed of the oil gap and the oil-soaked cardboard 5 The oil-paper composite insulation structure, the three-electrode system is put into the test oil tank 9, the opening of the test oil tank 9 is covered with a cover plate 10, the test oil tank 9 is vacuumed, and then the transformer oil is vacuum injected into the test oil tank 9, and it is completed after standing still. Assembly of the test device;

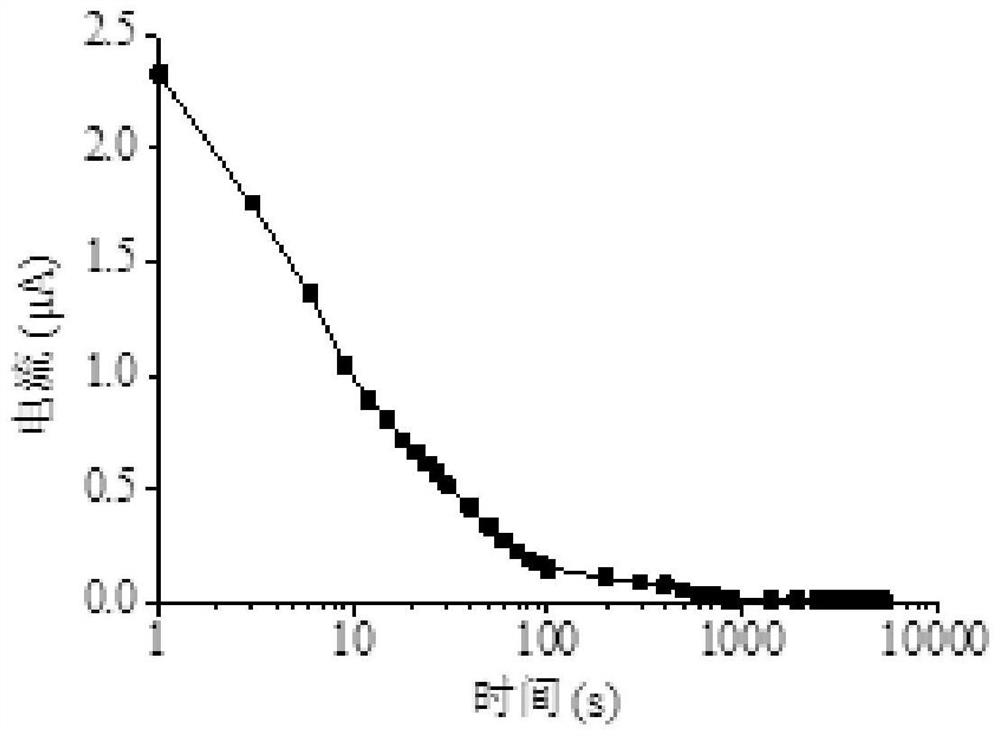

[0027] 2. Apply DC high voltage to the three-e...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that Step 2 applies a DC high voltage of 50 kV to 90 kV.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the DC high voltage is applied in step 2, and the pressurization time is 5400s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com