Cold rolling flatness quality judgment method based on fuzzy algorithm

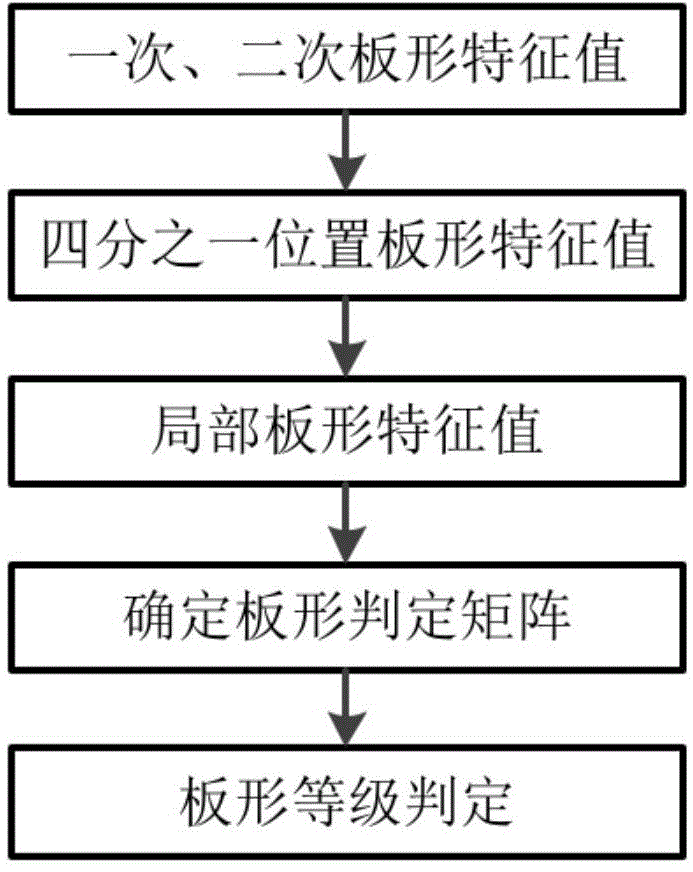

A technology of fuzzy algorithm and judgment method, applied in the direction of contour control, etc., can solve the problem of no cold-rolled flat shape judgment method found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

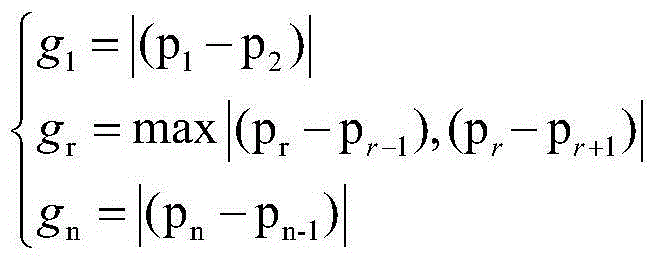

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

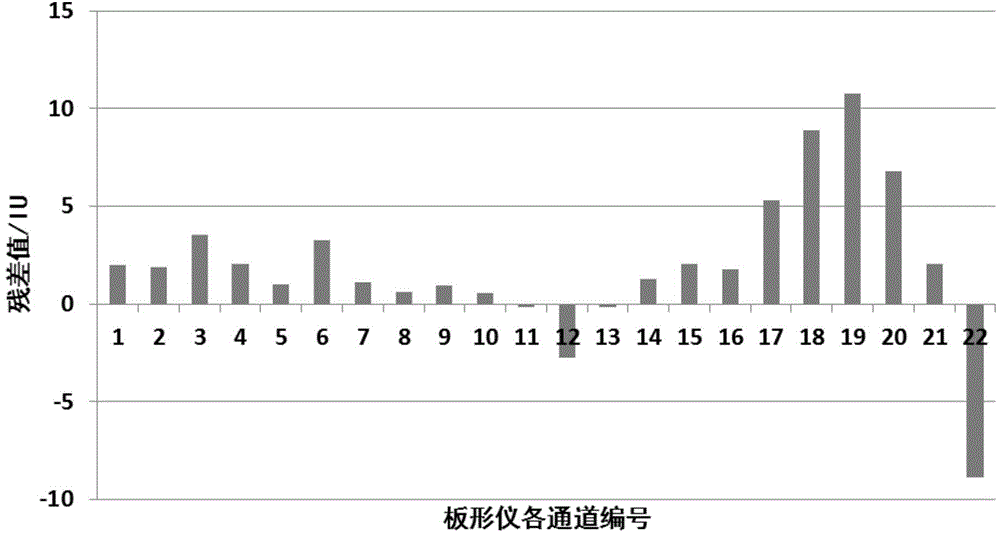

[0070] Taking the actual data measured by the shape meter in the production of a cold-rolled coil factory in China as an example, when producing strip steel of a certain specification, the shape meter opened 22 effective channels in total, and detected 327 sets of data in total, with a total of 7194 shapes Record the value, and make a comprehensive fuzzy score judgment on all the shape residual data as follows:

[0071] Take the 100th detection data as an example, such as figure 2 shown. The shape residual data are shown in Table 1 below:

[0072] Table 1 The residual data table of the measured flatness meter

[0073] channel number

channel number

1

1.99

12

-2.77

2

1.87

13

-0.15

3

3.56

14

1.27

4

2.03

15

2.02

5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com