Elastic traction means and method for the production thereof

A traction device and elastic technology, applied in the direction of belt fasteners, transmission belts, V-shaped belts, etc., can solve the problems of reduced tensile strength and tensile load strength of traction devices, and achieve the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

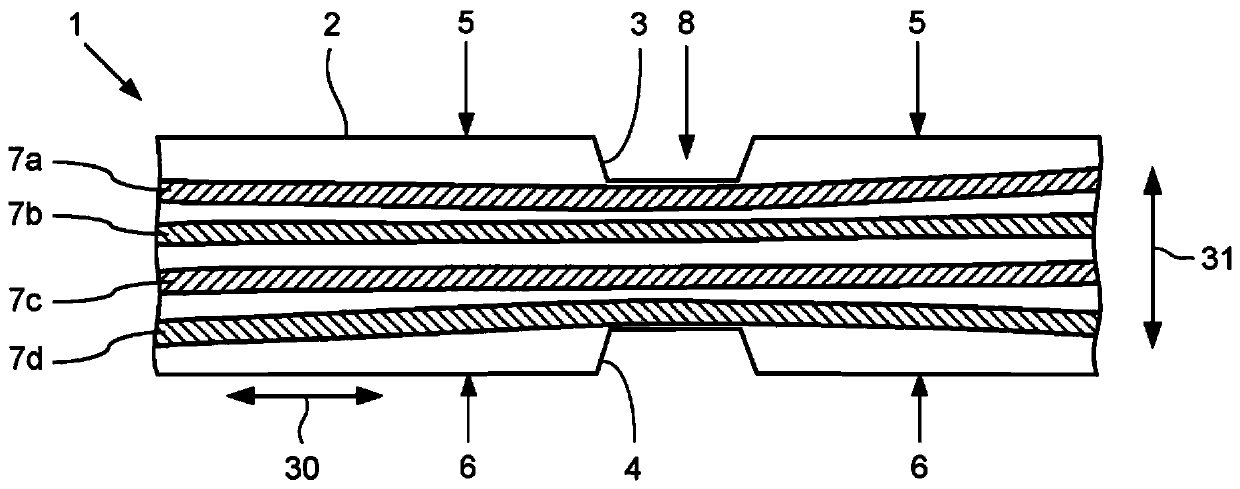

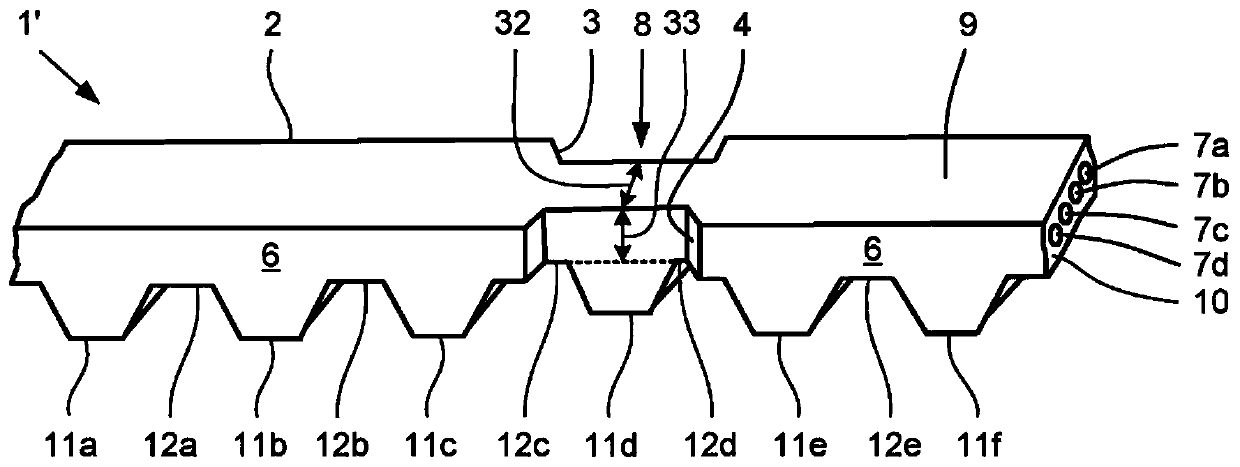

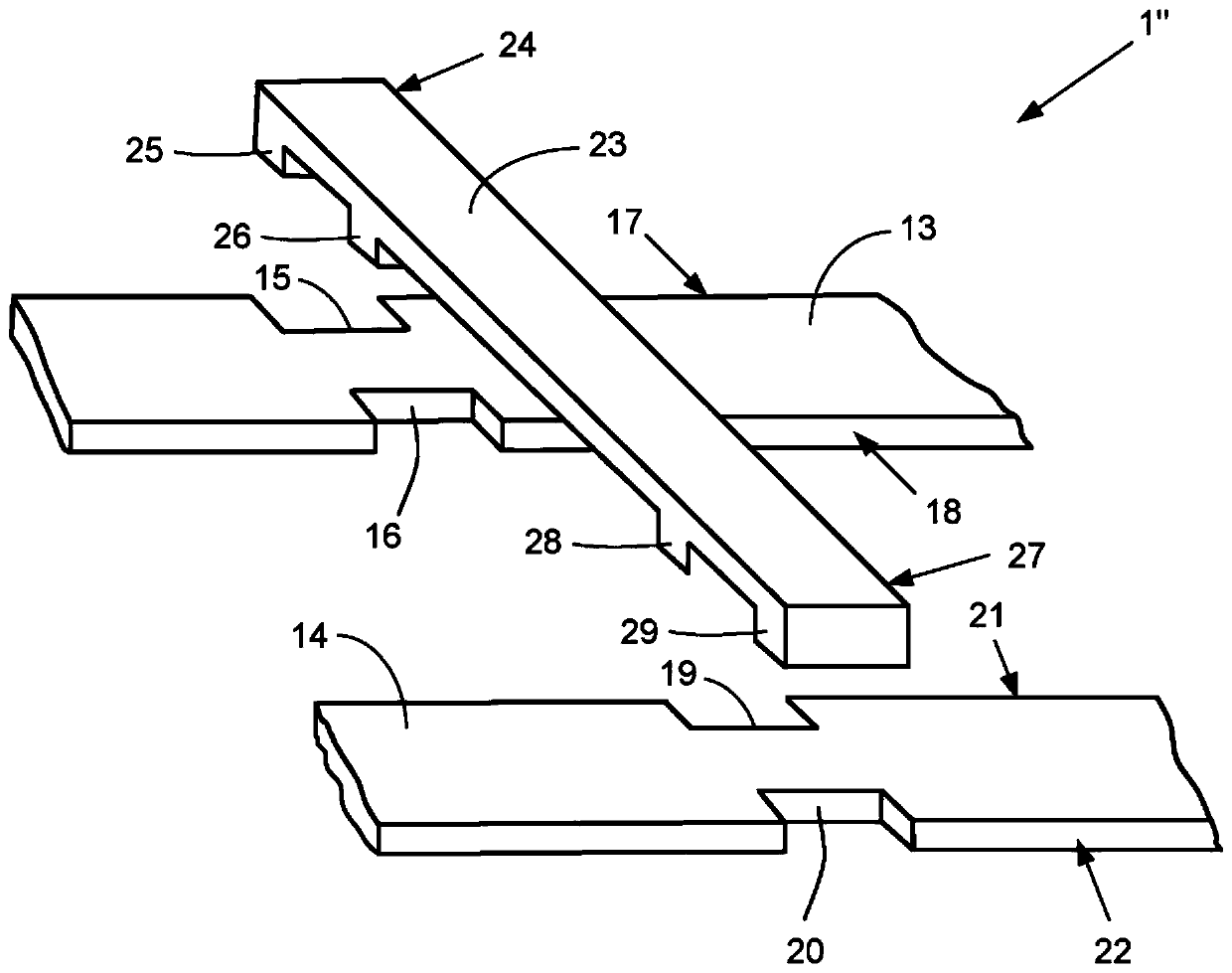

[0037] figure 1 Correspondingly, a longitudinally cut section of the solidified, elastic traction means 1 in the form of a wedge-shaped strip is shown. The wedge shape cannot be seen due to the chosen sectioning plane. The traction device 1 has a strip body 2 with a first depression 3 and a second depression 4 formed on a longitudinally directed first end side 5 or on a longitudinally directed second end side 6 of the strip body 2 or vice versa. ground layout. The two depressions 3 , 4 each have a trapezoidal geometry. A first tensile carrier 7 a , a second tensile carrier 7 b , a third tensile carrier 7 c and a fourth tensile carrier 7 d are embedded in the belt body 2 . The four tensile carriers 7a, 7b, 7c, 7d are designed as cords which extend substantially parallel to each other in the longitudinal direction 30 of the traction device 1, wherein the cords are spaced apart from each other. Each tensile carrier 7 a , 7 b , 7 c , 7 d is thus surrounded by the elastic base ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap