Adaptive cleaning grain harvester

A harvester and self-adaptive technology, which is applied in the field of agricultural machinery, can solve the problems that the sieve is difficult to screen, accumulate, and increase the loss of cleaning, so as to avoid the slippery and accumulation tendency of materials, ensure the harvest quality, and reduce the Effect of sieve loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

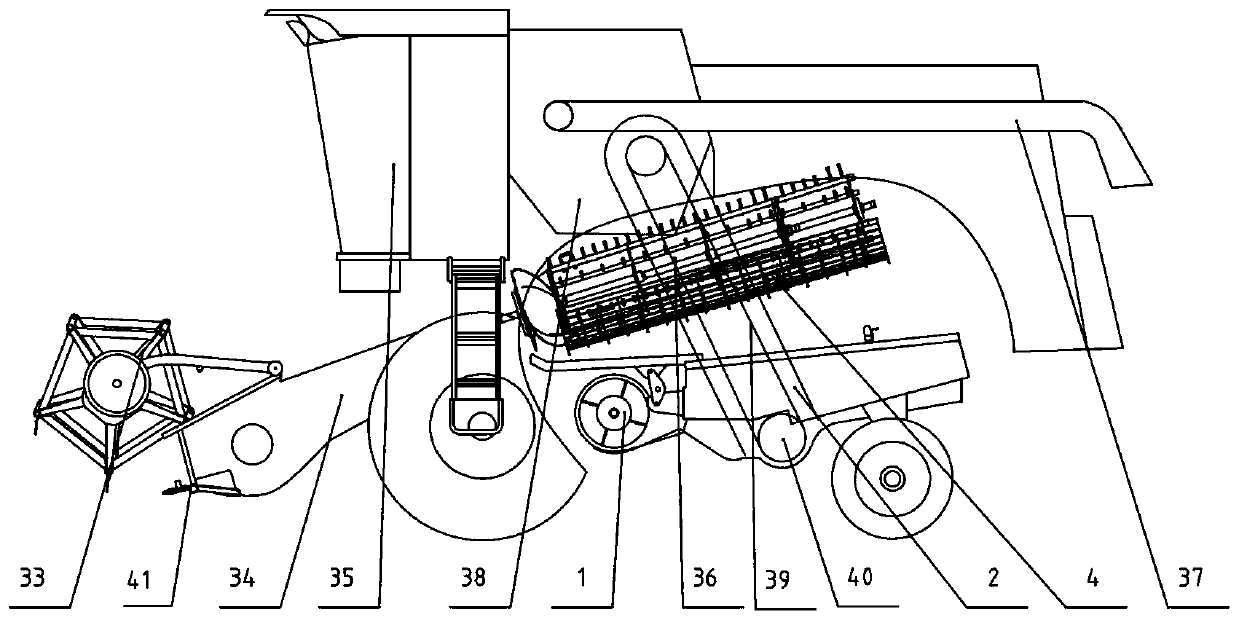

[0034] The self-adaptive cleaning grain harvester of the present embodiment is a preferred embodiment of the present invention, and its basic structure is as follows: figure 1 As shown, the front top of the machine is provided with a cab 35, and the front end of its walking chassis is equipped with a header mainly composed of a reel 33 and a cutting device 42. Separator connection. The threshing and separating device is similar to the prior art, and mainly consists of a threshing drum 36 and the concave screen 4 below it. An adaptive grain cleaning device is installed below the concave plate screen of the threshing separation device. The bottom output end of the grain cleaning device passes through the horizontal grain conveying auger 40 and the vertical grain conveying auger 39 connected with it and the grain unloading agitator. The grain collection box 38 of dragon 37 connects.

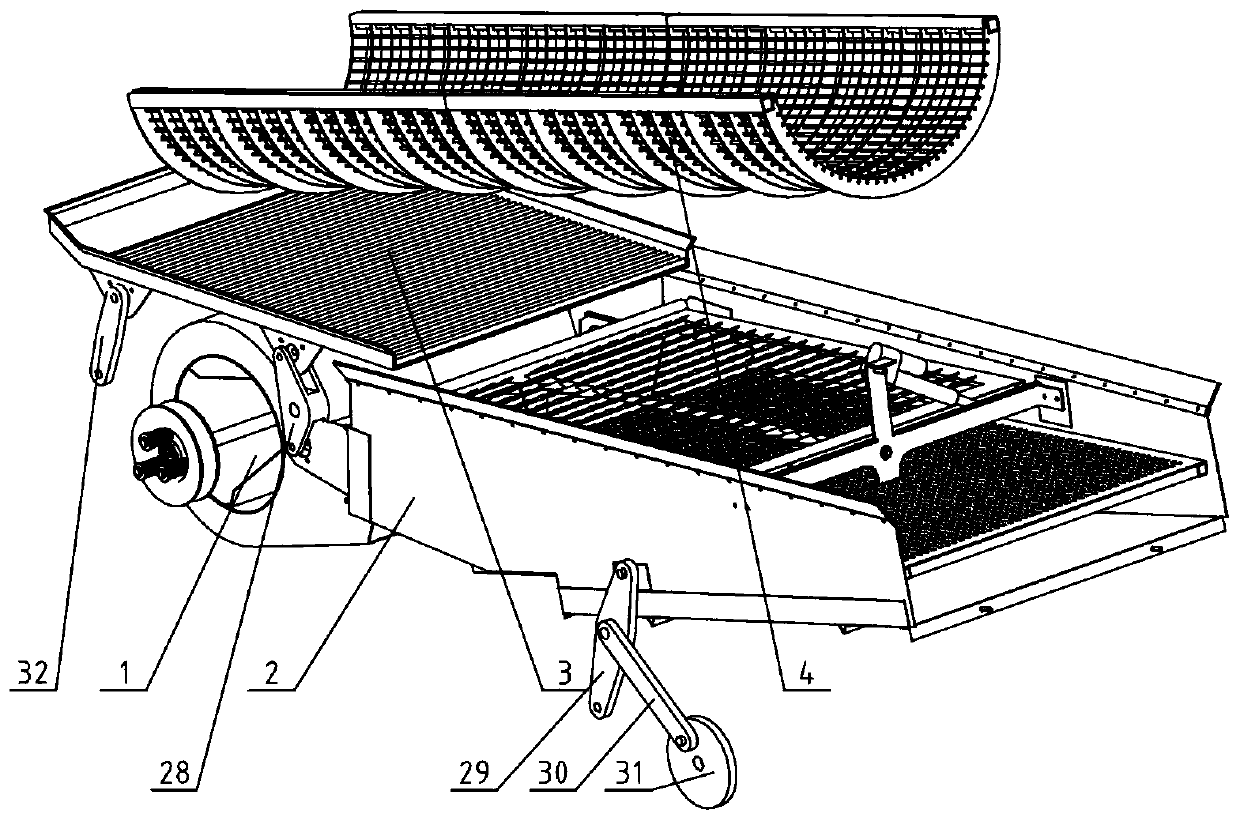

[0035] The specific structure of the adaptive cleaning device is as follows: figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com