A material preparation method for homogenization of raw material components and delivery from warehouse

A homogenization and raw material technology, applied in the field of tobacco chemical industry, can solve the problem that it is difficult to eliminate the large-scale fluctuation of nicotine content, and achieve the effect of improving the calculation efficiency of discharging materials, saving the working hours of discharging materials, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be further described in detail below.

[0030] The material preparation method for homogenization and delivery of raw material components described in the present invention is mainly applicable to the situation where it is necessary to mix raw materials with different contents of active ingredients such as tobacco and obtain a homogenization target value.

[0031] In tobacco leaves, even in different bales of the same batch of tobacco leaves, due to differences in picking time, location, storage and other processes, the nicotine content in them is also different. For example, for five bales of the same batch, the infrared detection In other ways, it can be found that the nicotine content of each cigarette pack is different.

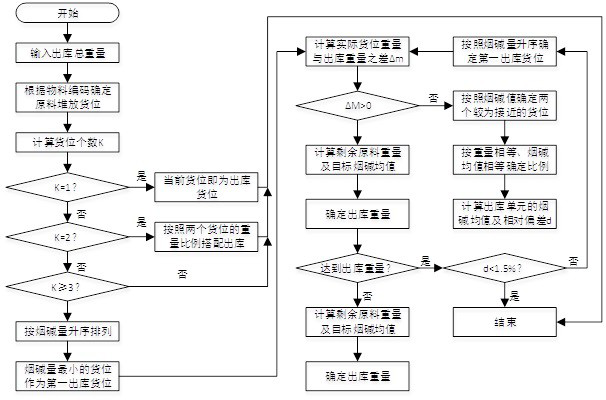

[0032] When there are more than three different contents of the active ingredient in the raw material, the material selection steps are as follows:

[0033] Step 1. Determine the homogenization ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com