Chemical raw material smashing mechanism and smashing and screening device

A technology of chemical raw materials and crushing mechanism, which is applied in the direction of filtration, chemical instruments and methods, solid separation, etc., can solve the problems of long crushing time, low production efficiency, small crushing range, etc., and achieve improved crushing efficiency, sufficient crushing, and expanded The effect of smashing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

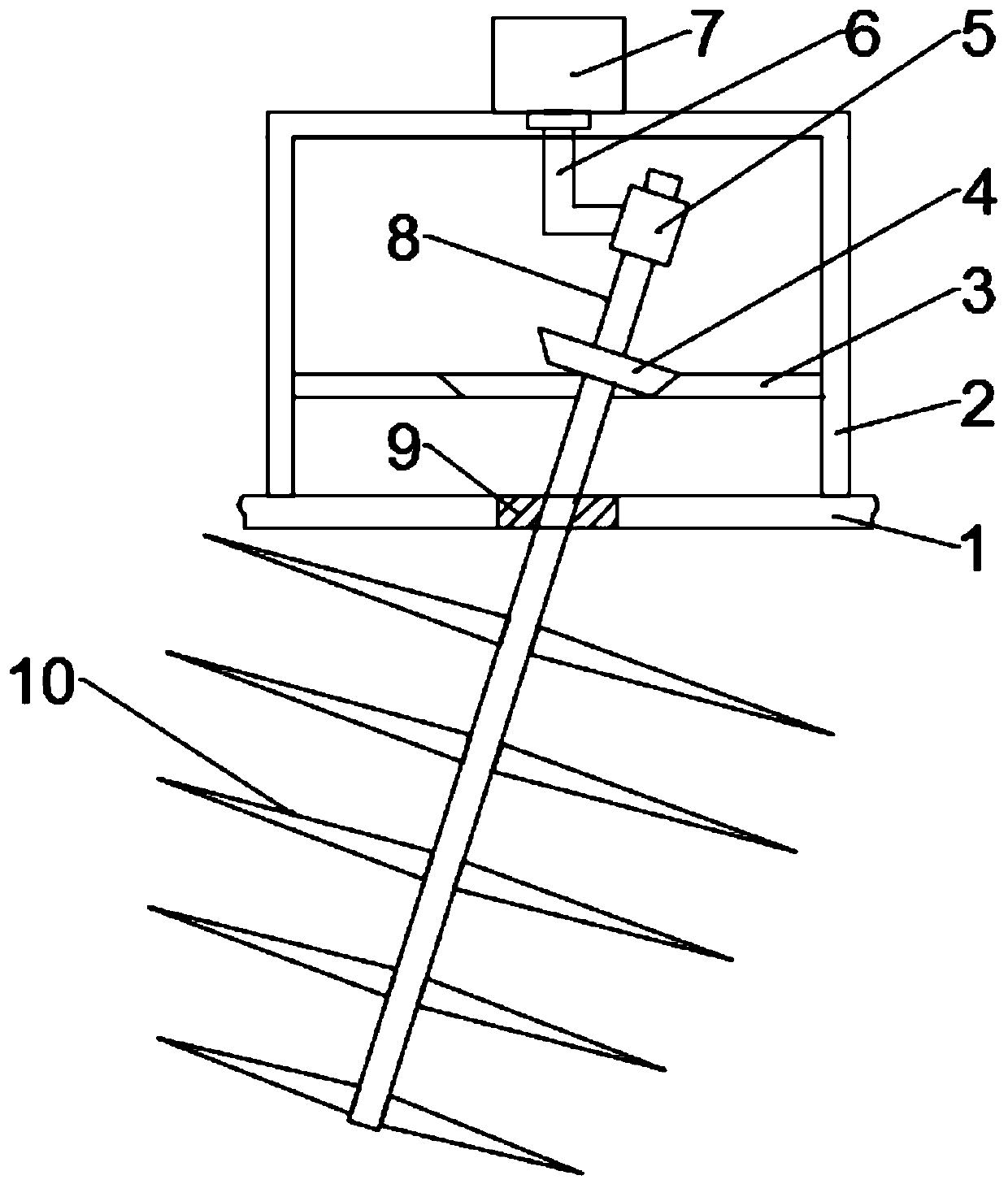

[0020] see figure 1 , in the embodiment of the present invention, a chemical raw material crushing mechanism, the chemical raw material crushing mechanism is installed in the crushing box 1, including a motor 7, a rotating shaft 8 and a crushing blade 10, and the motor 7 is installed in the crushing box through the mounting bracket 2 1, the output shaft of the motor 7 is fixedly connected with an L-shaped rod 6 through a coupling, and the short side end of the L-shaped rod 6 is welded and fixed with a sleeve 5, and the other end of the rotating shaft 8 runs through the top of the crushing box 1 and extends to In the crushing box 1, the rotating shaft 8 is connected to the top of the crushing box 1 through a universal bearing 9, and the rotating shaft 8 is arranged obliquely. Rotating shaft 8, a bevel gear 4 is installed on the shaft section above the crushing box 1, an inner bevel gear 3 is installed on the mounting frame 2, the connection mode between the internal bevel gear ...

Embodiment 2

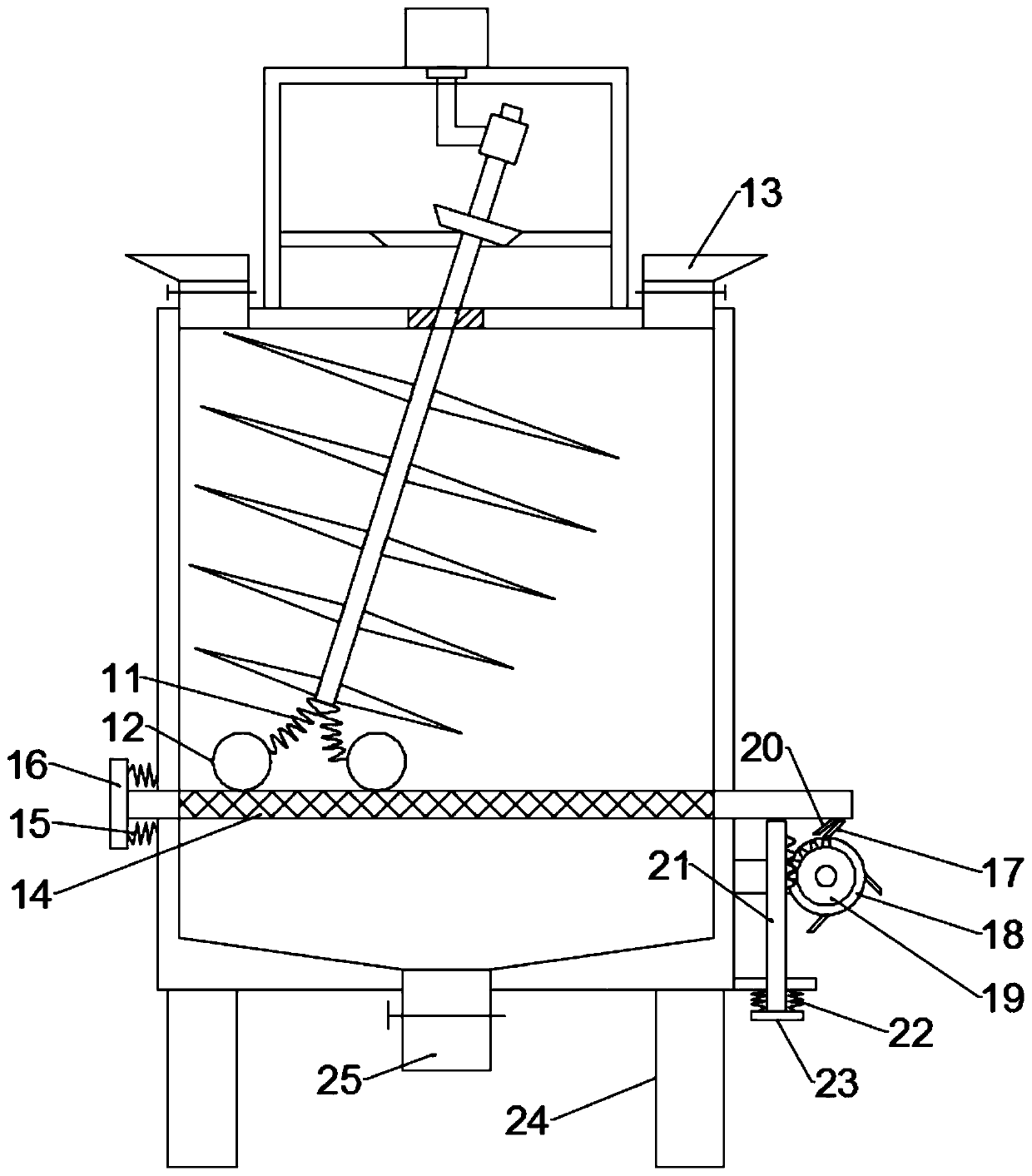

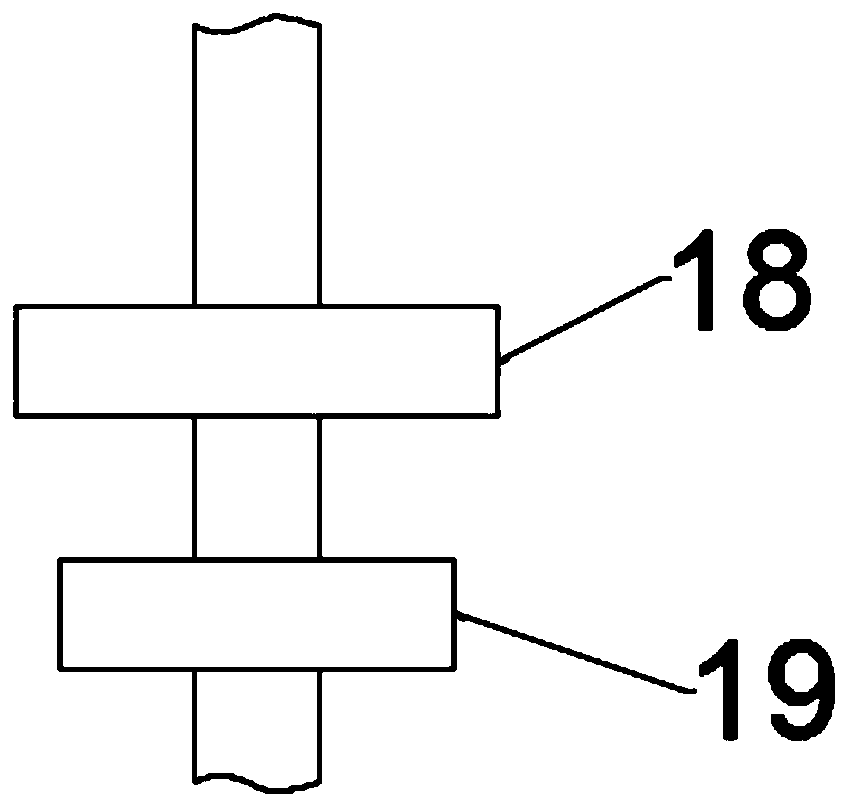

[0022] see Figure 2-3 , a chemical raw material crushing and screening device, including the chemical raw material crushing mechanism described in embodiment 1, and also includes a screen 14 and a grinding ball 12, four corners of the bottom of the crushing box 1 are equipped with supporting legs 24, the crushing box 1 There are feeding ports 13 on both sides of the top, and a discharging port 25 is arranged in the middle of the bottom of the crushing box 1. Valves are installed on both the feeding port 13 and the discharging port 25, and the bottom of the inner cavity of the crushing box 1 is discharged from both sides. The mouth 25 is inclined to facilitate discharging. A screen 14 is installed below the rotating shaft 8 in the crushing box 1. The two sides of the screen 14 run through the side wall of the crushing box 1 and extend to the outside of the crushing box 1. The guide through hole for the movement of the screen 14, the first fixed plate 16 is installed on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com