Bag making machine

A bag making machine and rack technology, applied in bag making, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of high labor intensity, complex structure, low degree of automation, etc., to improve production efficiency and structure. Compact, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

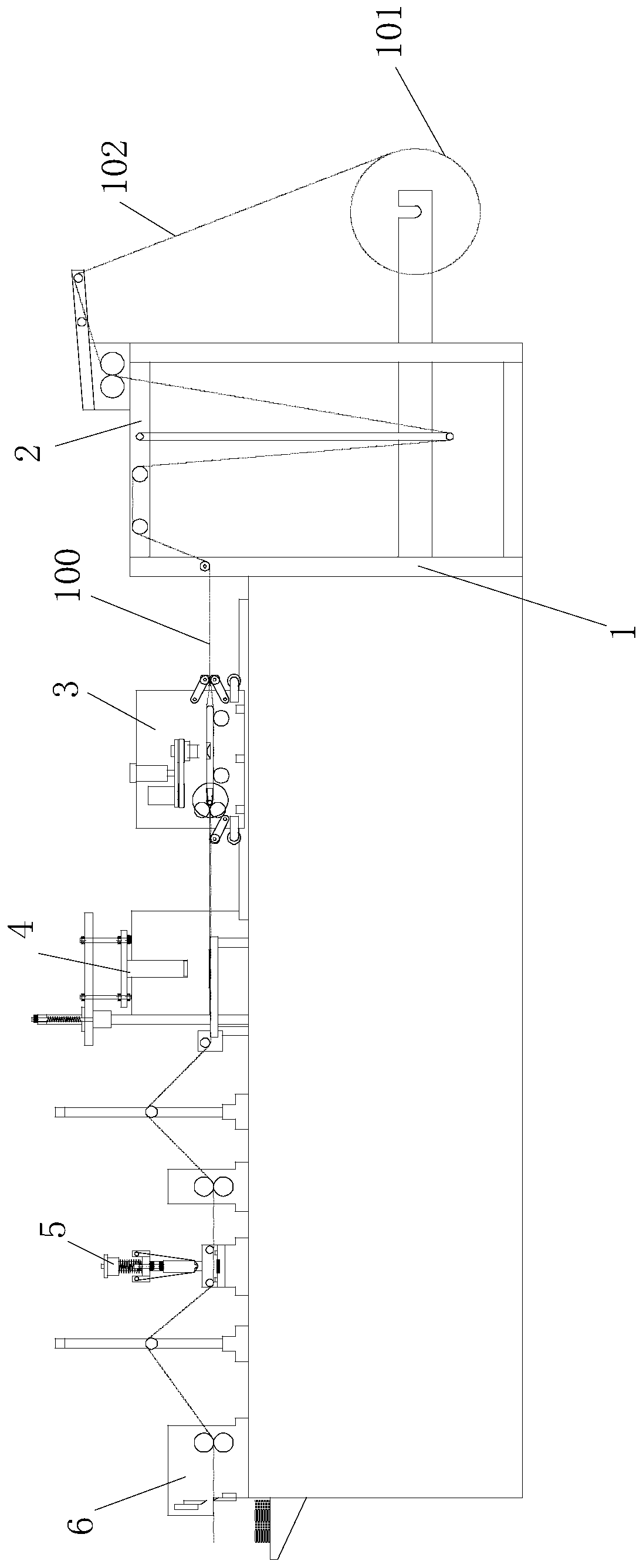

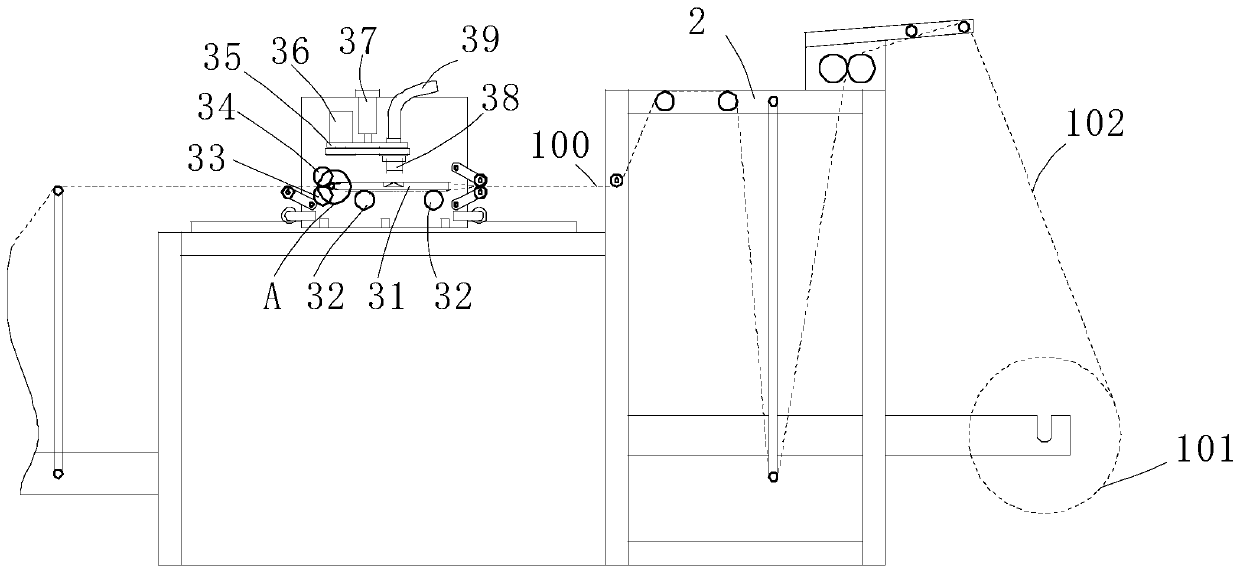

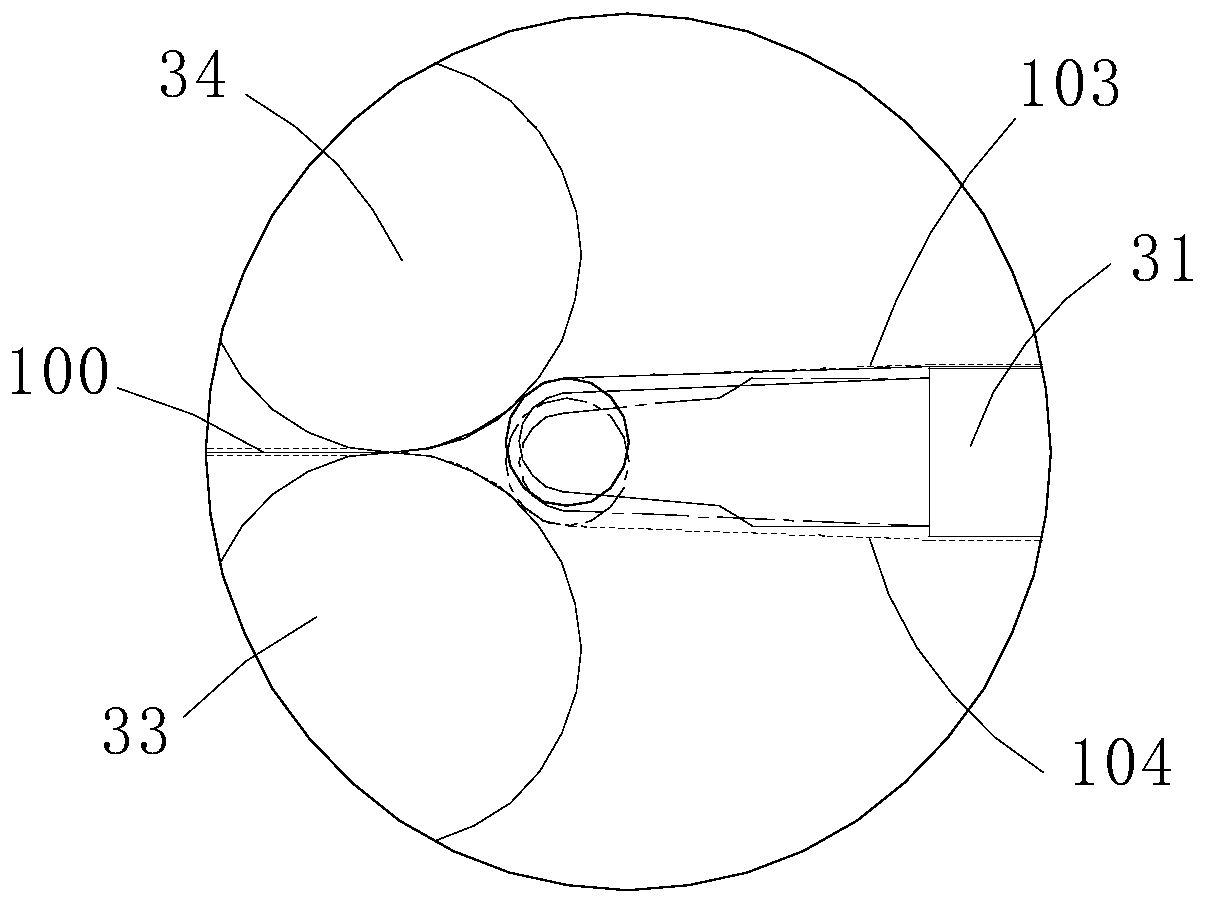

[0038] This embodiment relates to a bag-making machine for processing one side of a straight-through bag. The straight-through bag has a through hole arranged through the head to the tail. The bag-making machine includes a frame. One end of the frame to the other end of the intermittent continuous horizontal feeding mechanism, and a single-side punching device for punching one side of the straight-through bag, and a welding device for welding the gas-permeable film on the single-sided hole on the straight-through bag, and also includes The gas-permeable film feeding mechanism is perpendicular to the conveying direction of the straight-through bag to form the conveying of the gas-permeabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com