Cleaning device for cleaning conveying belt type bristle bed cutting table and application method of cleaning device

A technology for cleaning devices and cutting tables, which is applied to cleaning devices, transportation and packaging, and conveyor objects, etc. It can solve the problems of wasting manpower and low work efficiency, and achieve the effects of labor saving, convenient operation, and cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

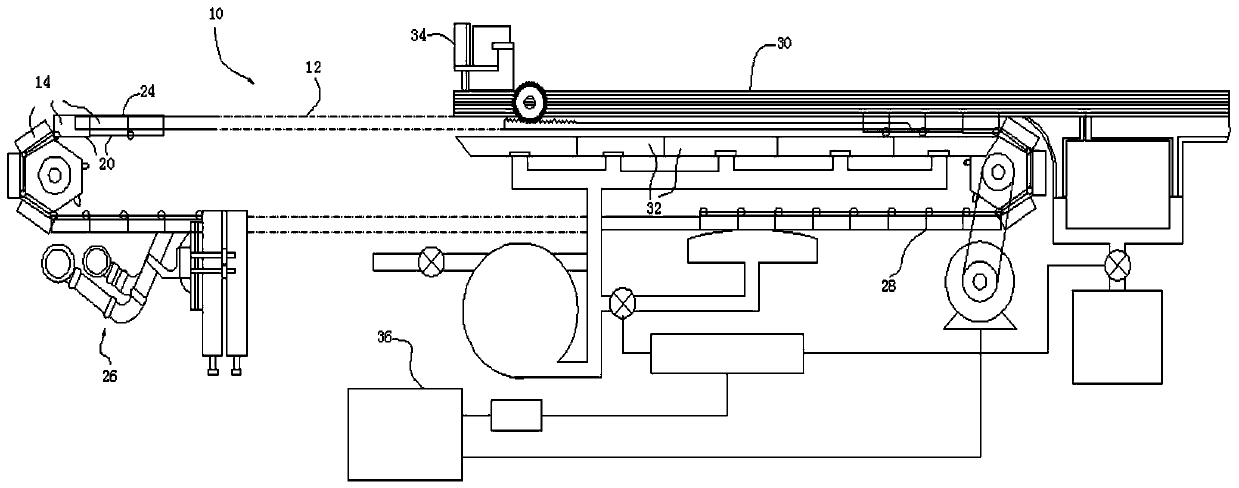

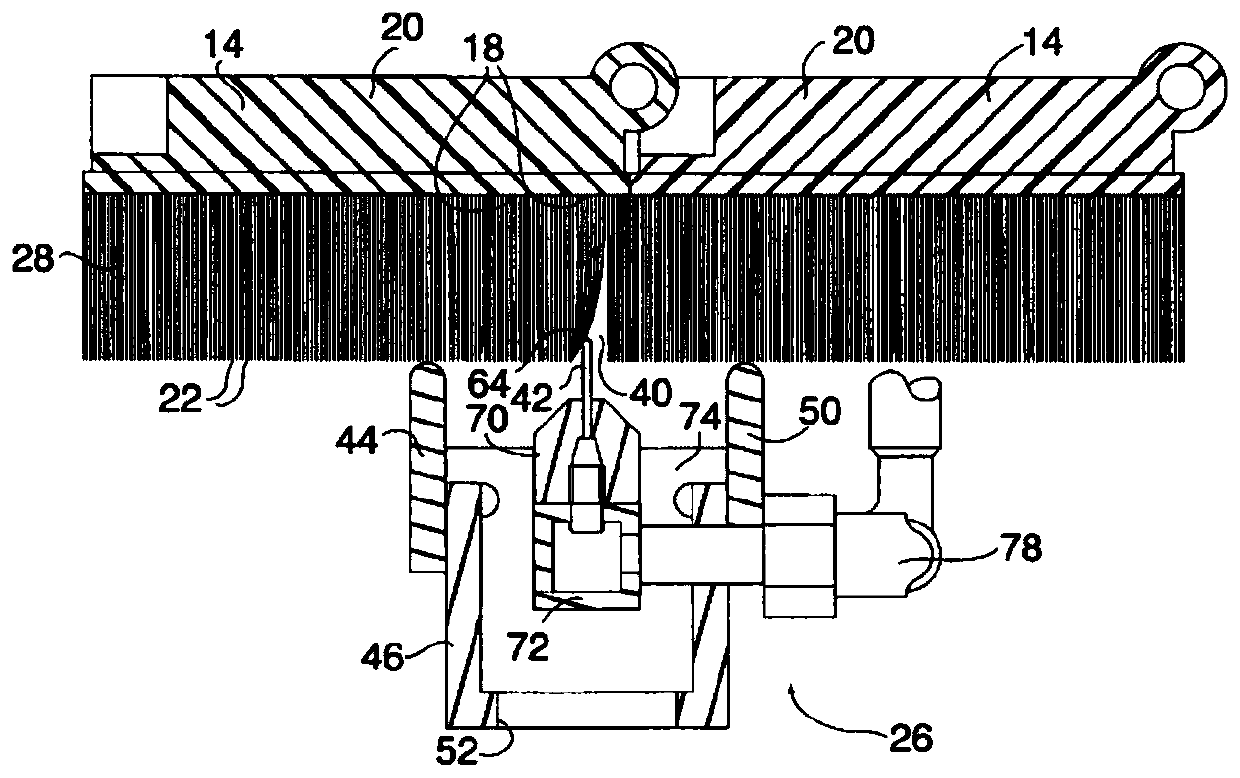

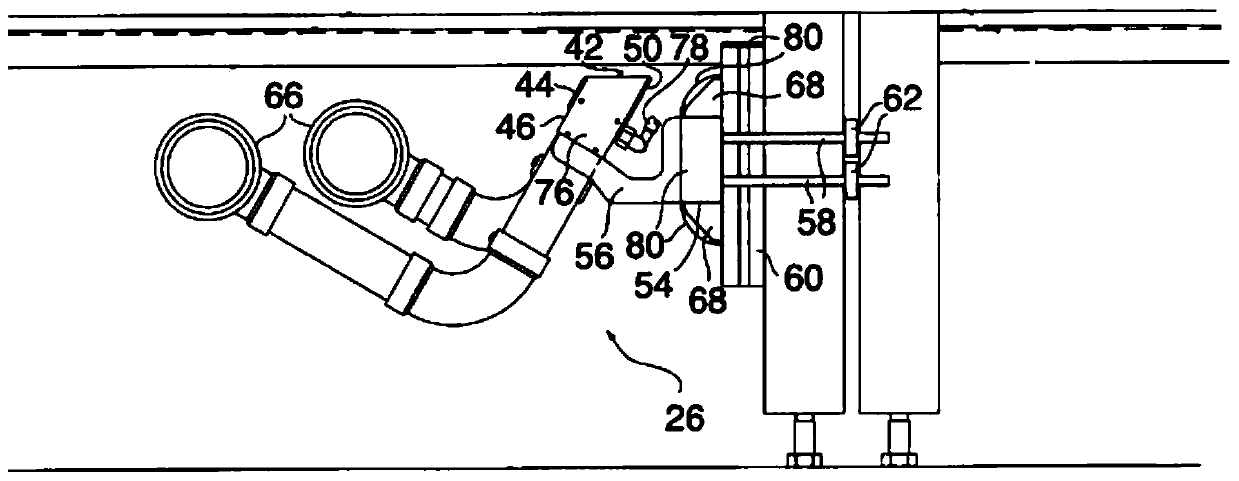

[0028] The present invention provides such Figure 1-6 A kind of cleaning device that is used to clean the conveyor belt type bristle bed cutting table shown, comprises sheet cutting machine 10, and endless belt conveyor 12 is installed on the sheet cutting machine 10, and described endless belt conveyor 12 Evenly distributed bristle blocks 14 are fixedly installed on the upper surface, and a cleaning mechanism 26 is fixedly installed on one side of the bottom of the endless belt conveyor 12. The cleaning mechanism 26 includes a cleaner bracket 56, and the inside of the cleaner bracket 56 The vacuum inlet chamber 46 is connected through the end plate 76, and the first limiting plate 44 and the second limiting plate 50 are respectively welded symmetrically on both sides of the top of the vacuum inlet chamber 46, and the first limiting plate 44 and the second limiting plate 50 are respectively welded symmetrically. A partition 74 is welded between the two limiting plates 50, a v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap