Material transfer device

A technology of unloading device and conveying device, which is applied in the field of fiber processing, can solve the problems of troublesome material transfer and can not meet the requirements of use, and achieves the effects of simple disassembly and assembly, quick and convenient disassembly and assembly, and easy reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

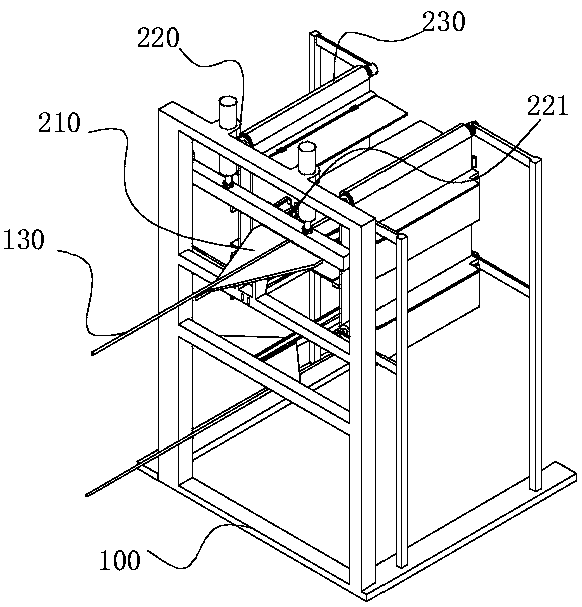

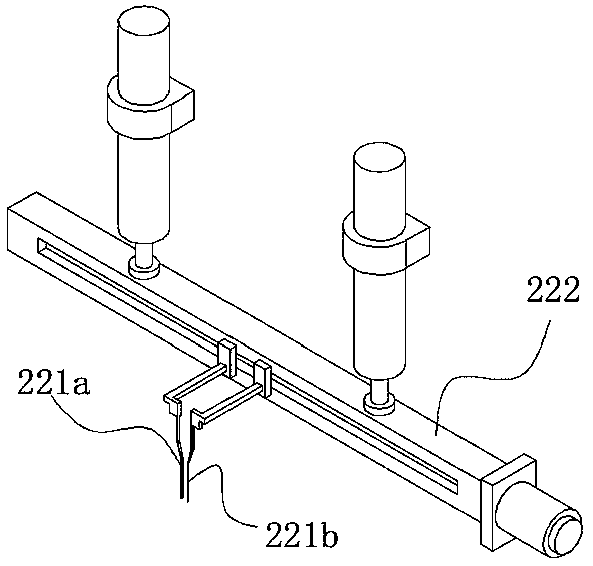

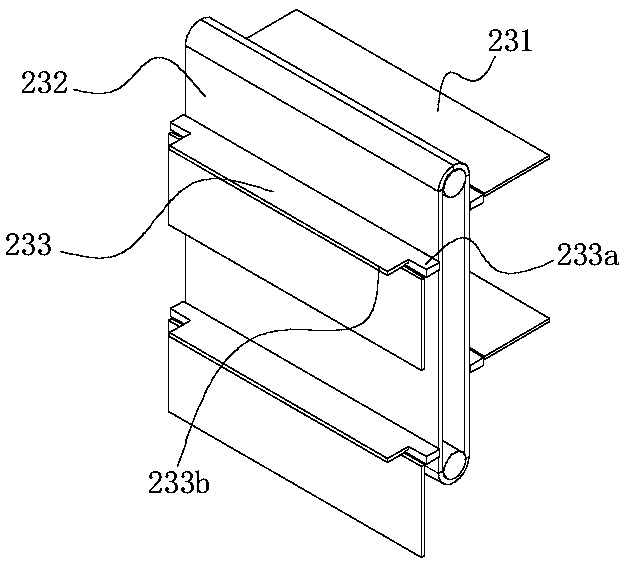

[0033] refer to Figure 4-7 , a continuous fiber transfer device is proposed in the embodiment of the present invention, comprising a frame 100, a discharge device 200 is installed on the frame 100, a supporting surface 231a is provided on the discharging device 200, and the supporting surface 231a is used for For lifting fibers, the supporting surface 231a is provided with an area for the conveying device 130 to pass through, and the middle part of the fiber is suspended in the area where the conveying device 130 passes. 330 and transfer mechanism 310. The lifting mechanism 330 is used to lift the carrier 340. During the movement of the carrier 340 from bottom to top, it lifts up the suspended fiber body in the middle, and the carrier 340 can pass through the suspended area of the fiber body. The transfer mechanism 310 drives the carrier 340 away from the unloading device 200 and transfers it to the next process.

[0034] The projected length of the bearing part 340 on the...

Embodiment 2

[0057] refer to Figure 1-7 , a fiber continuous unloading device, including a frame 100, a conveying device 130 is arranged on the frame 100, the conveying device 130 is used to convey fibers, the middle part of the fiber is set on the conveying device 130, and the two ends are suspended downwards Arrangement; the frame 100 is provided with a moving mechanism 230, the moving mechanism 230 is connected to the supporting surface, the moving mechanism 230 can drive the supporting surface to move from the bottom of the conveying device 130 to the top of the conveying device 130, and the supporting surface is from below the conveying device 130 to During the movement above the conveying device 130 , the supporting surface contacts and holds up the suspension section of the fiber, and the fiber is taken out from the conveying device 130 , and the supporting surface is provided with an area for the conveying device 130 to pass through.

[0058] The supporting surface is arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com