Color-change indication thermosetting glue and color-change indication thermosetting conductive adhesive

A technology of thermosetting adhesives and conductive adhesives, applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of time lag, complicated detection process, and inability to immediately understand the degree of curing, so as to reduce production losses and timely Production status and the effect of saving testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

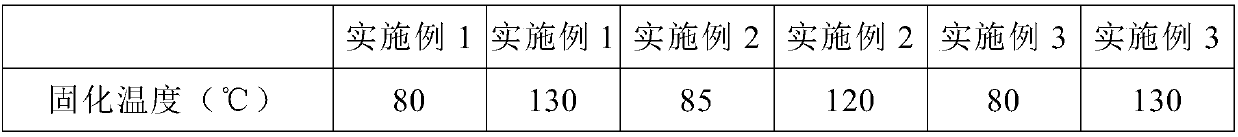

Embodiment 1

[0050] A color-changing indicating thermosetting glue, the color-changing indicating thermosetting glue includes bisphenol A epoxy resin, methyltetrahydrophthalic anhydride, 4-dimethylaminopyridine, fumed silica anti-settling agent R972 and irreversible thermosensitive discoloration pigment.

[0051] The bisphenol A epoxy resin has a mass percentage range of 50% in the discoloration indicating thermosetting glue; the mass percentage content of the methyltetrahydrophthalic anhydride in the discoloration indicating thermosetting glue is 40% %; the mass percentage range of the 4-dimethylaminopyridine in the discoloration indicating thermosetting glue is 2%; the mass percentage range of the R972 in the discoloration indicating thermosetting glue is 2%; the The mass percent content range of the heat-sensitive color-changing pigment in the color-changing indicating thermosetting glue is 6%.

[0052] The curing temperature of the bisphenol A epoxy resin is about 130 degrees Celsius;...

Embodiment 2

[0054] Disclosed is a color-changing indicating thermosetting glue, which includes polyester polyol resin, polyurethane curing agent BL3175 SN, fumed silica anti-settling agent R972 and irreversible thermosensitive color-changing pigments.

[0055] The mass percentage range of the polyester polyol resin in the discoloration indicating thermosetting glue is 74%; the mass percentage content of the polyurethane curing agent BL3175 SN in the discoloration indicating thermosetting glue is 8%; The mass percentage range of the R972 in the color-changing indicating thermosetting glue is 2%; the mass percentage content of the heat-sensitive color-changing pigment in the color-changing indicating thermosetting glue is 6%.

[0056] The curing temperature of the polyester polyol resin is about 120 degrees Celsius; the color changing temperature of the heat-sensitive color-changing pigment is about 120 degrees Celsius.

Embodiment 3

[0058] A color-changing indicating thermosetting conductive glue, the color-changing indicating thermosetting glue includes bisphenol A epoxy resin, methyltetrahydrophthalic anhydride, 4-dimethylaminopyridine, fumed silica anti-settling agent R972, silver powder and irreversible Heat-sensitive color-changing pigments.

[0059] The bisphenol A epoxy resin has a mass percentage range of 10% in the discoloration indicating thermosetting glue; the mass percentage content of the methyltetrahydrophthalic anhydride in the discoloration indicating thermosetting glue is 7% %; the mass percentage range of the 4-dimethylaminopyridine in the discoloration indicating thermosetting glue is 0.5%; the mass percentage range of the R972 in the discoloration indicating thermosetting glue is 0.5%; the The mass percentage range of the silver powder in the color-changing indicating thermosetting glue is 80%; the mass percentage content of the heat-sensitive color-changing pigment in the color-chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com