Multiwalled carbon nanotube-modified epoxy resin production and FRP-concrete bonding monitoring methods

A technology for preparing multi-walled carbon nanotubes and epoxy resin, which is applied in the field of concrete, can solve the problems of small elongation at break, poor effect, difficult structural service performance, etc., to achieve enhanced interface adhesion, convenient construction, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions, and advantages of the present invention clearer and more comprehensible, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

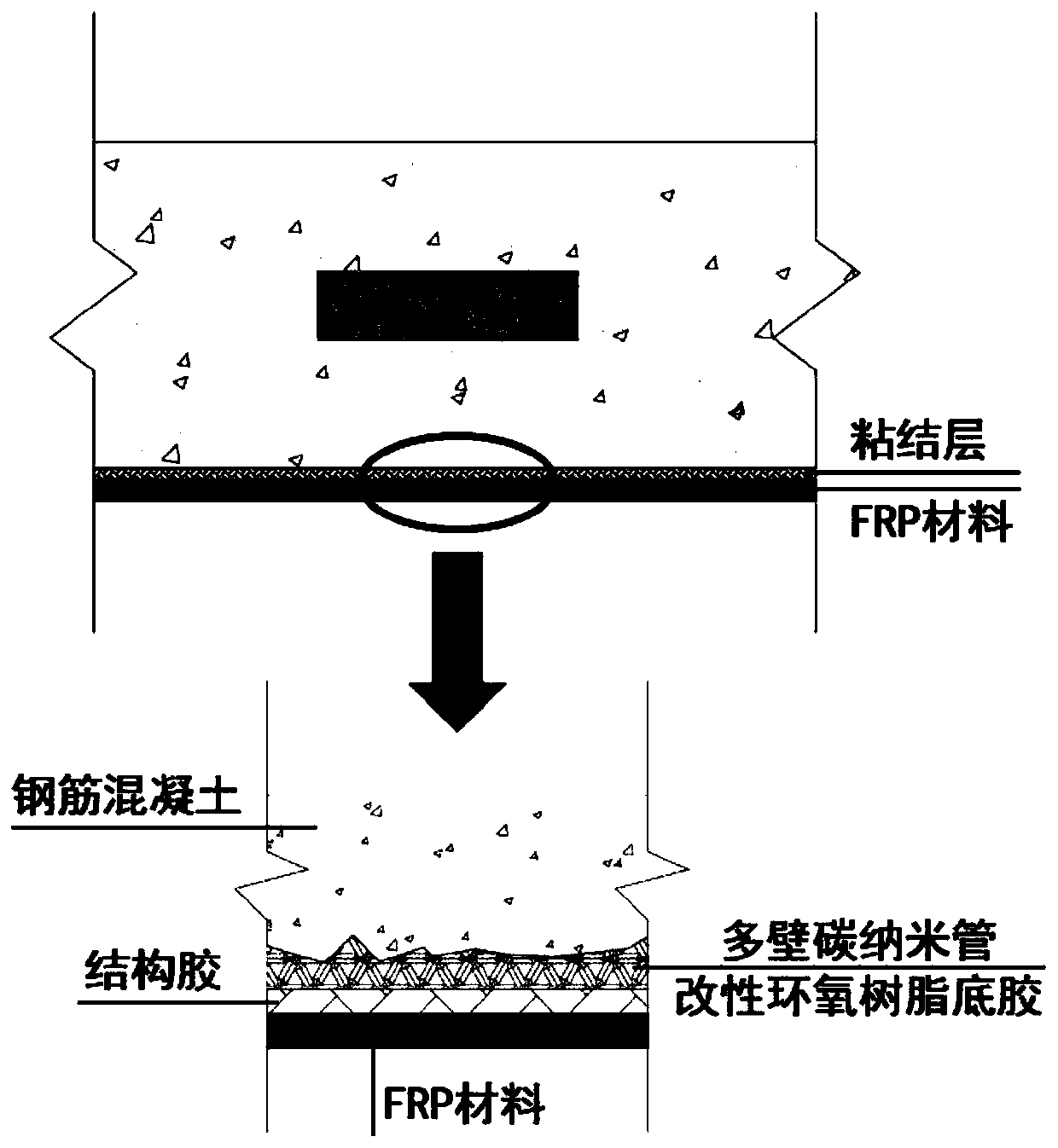

[0019] As shown in the figure, the preparation method of multi-walled carbon nanotube modified epoxy resin includes the following steps: 1) Preparation of materials: epoxy resin, curing agent, multi-walled carbon nanotubes and acetone; this process can be appropriate according to the curing time requirements Adding accelerators to speed up the curing time, the mass ratio of epoxy resin: accelerator is 100:0 to 100:5;

[0020] 2) Using ambient temperature to raise the epoxy resin to 40℃ has increased its fluidity; 3) Disperse the multi-walled carbon nanotubes in acetone. The function of acetone is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com