Composite electromagnetic field monitoring-type steel ladle breathable brick

A technology of air-permeable bricks and electromagnetic fields, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve problems such as extremely high requirements for argon blowing operations, reduce volume stability, and complex gas supply systems, and achieve real-time monitoring and use status, promotion of integration and synchronization, wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

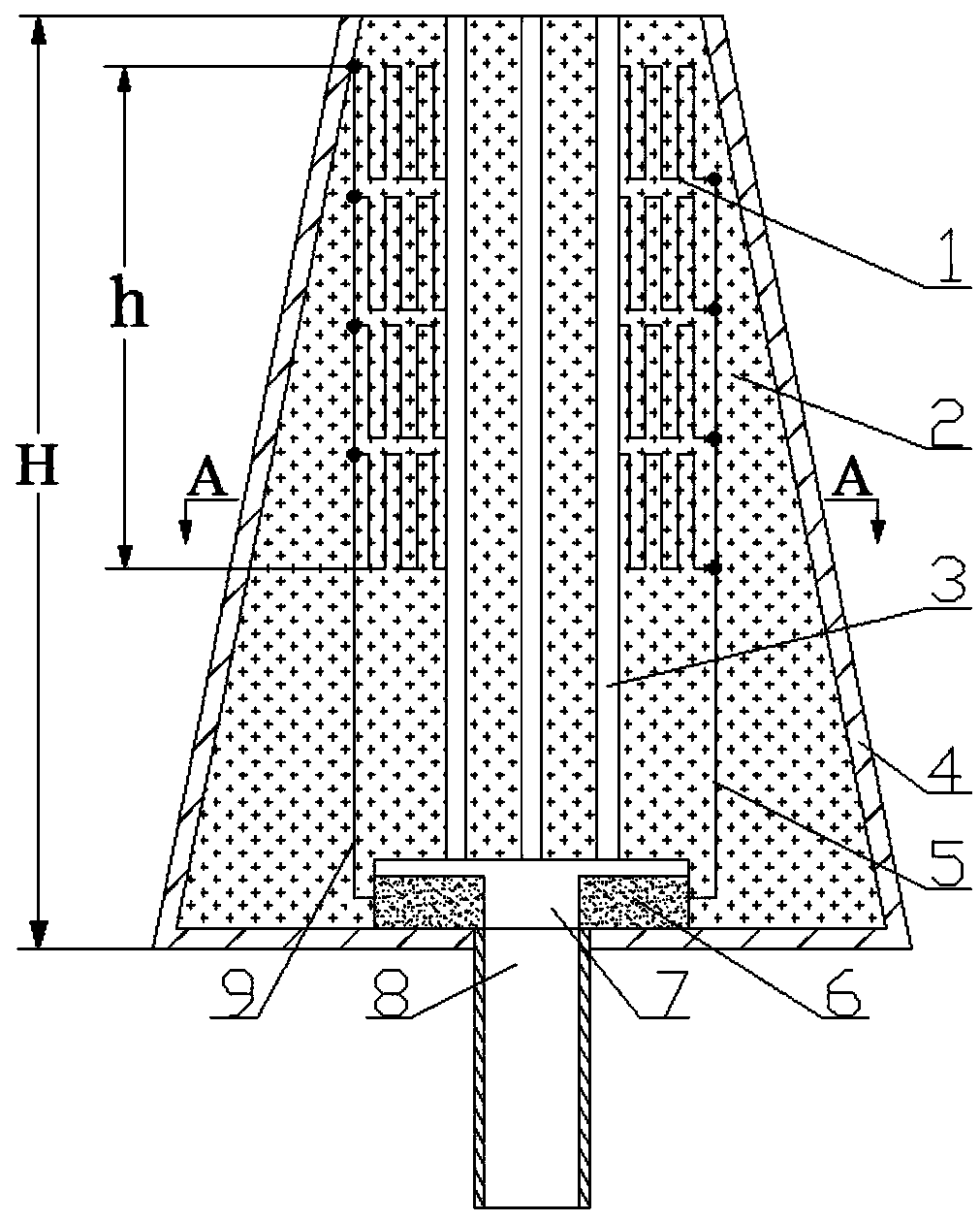

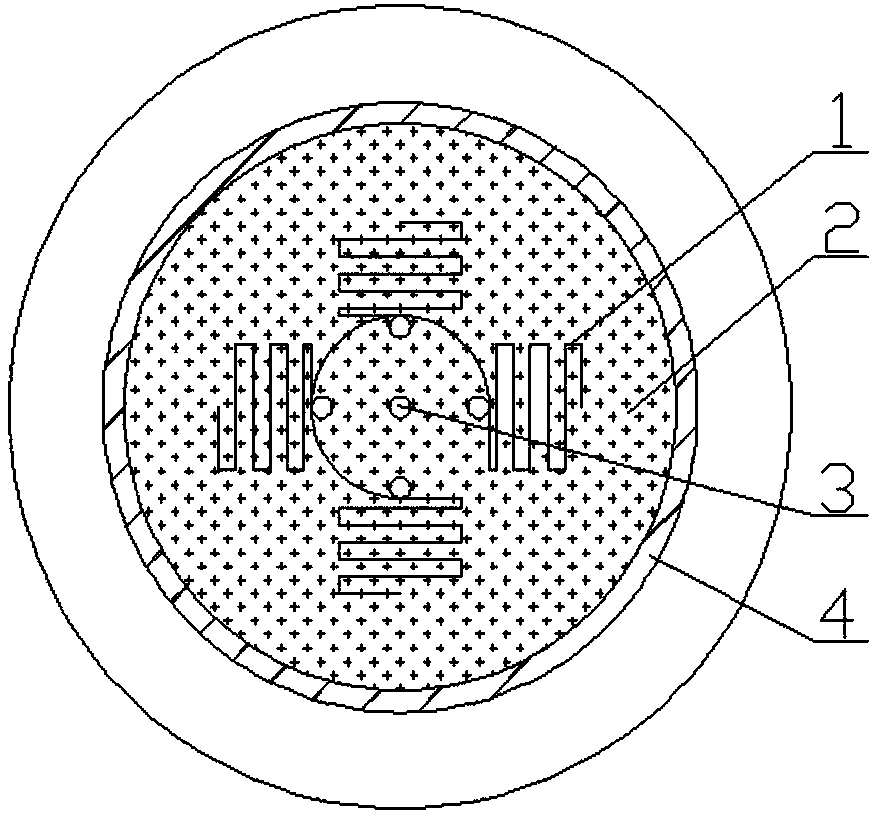

[0032] The utility model relates to a composite electromagnetic field monitoring type ladle ventilation brick. Such as figure 1 with figure 2 As mentioned above, the breathable brick includes a breathable brick core 2 , a breathable brick shell 4 , a power supply 6 and an air intake pipe 8 . The air permeable brick core 2 is in the shape of a circular platform, and the air permeable brick shell 4 is provided on the side and bottom of the permeable brick core 2 .

[0033] Such as figure 1 As mentioned above, the center of the bottom of the breathable brick core 2 is provided with a circular concave surface, and the circular concave surface and the bottom of the breathable brick shell 4 form a breathable chamber 7 . An air inlet pipe 8 is fixed at the center of the bottom of the air brick housing 4 , and the air inlet pipe 8 communicates with the air chamber 7 . The annular bottom of the air-permeable chamber 7 is provided with a power supply 6, and the power supply 6 is wi...

Embodiment 2

[0050] The utility model relates to a composite electromagnetic field monitoring type ladle ventilation brick. Except following technical parameter, all the other are with embodiment 1:

[0051] The shape of the power supply 6 is that 2 to 7 block batteries are connected in series to form a ring shape, the inner diameter of the ring of the power supply 6 is 1 to 1.2 times the inner diameter of the air intake pipe 8, and the outer diameter of the ring of the power supply 6 is the diameter of the gas chamber 7. The diameter is 0.75-0.85 times, and the height of the power supply 6 is 0.6-0.7 times the height of the air-permeable chamber 7 .

[0052] Such as figure 1 with figure 2 As mentioned above, 6 to 29 ventilating slits 3 are vertically arranged in the ventilating brick core 2, and 6 to 29 ventilating slits 3 are evenly located above the ventilating chamber 7, and 6 to 29 ventilating slits 3 are all connected to Breathable chamber 7 communicates.

[0053] Such as figur...

Embodiment 3

[0065] The utility model relates to a composite electromagnetic field monitoring type ladle ventilation brick. Except following technical parameter, all the other are with embodiment 1:

[0066] The shape of the power supply 6 is that 8 block batteries are connected in series to form a ring shape, the inner diameter of the ring of the power supply 6 is 1 to 1.2 times the inner diameter of the intake pipe 8, and the outer diameter of the ring of the power supply 6 is the diameter of the gas chamber 7. 0.8 to 0.9 times, the height of the power source 6 is 0.7 to 0.8 times the height of the air-permeable chamber 7 .

[0067] Such as figure 1 with figure 2 As mentioned above, 30 ventilation slits 3 are vertically arranged in the ventilation brick core 2, and the 30 ventilation slits 3 are evenly located above the ventilation chamber 7, and all the 30 ventilation slits 3 communicate with the ventilation chamber 7.

[0068] Such as figure 1 with figure 2 As mentioned above, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com