A multi-stage water pump type weaving beating-up device

A water pump and connection device technology, applied in the field of multi-stage water pump type weaving beating-up device, can solve the problems of not being able to keep up with the technology and the number of weft yarns is relatively large, and achieve the expansion of the weaving range, long service life, and vibration of the whole machine small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

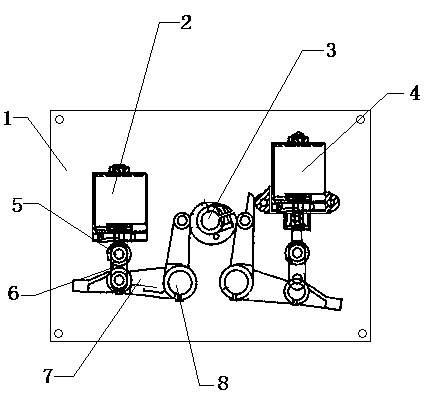

[0011] This embodiment provides a multi-stage water pump type weaving beating-up device, which is characterized in that: the multi-stage water pump type weaving beating-up device includes an installation chassis (1), an A-level water pump (2), a connecting cam (3), Class B water pump (4), water pump power output rod (5), connecting rod (6), swing rod (7), pin shaft (8);

[0012] Among them: including the A-level water pump (2) and the B-level water pump (4) installed on the installation base (1), and the connection device between the A-level water pump (2) and the B-level water pump (4), the A-level water pump (2) ) of the water pump power output rod (5) is installed and connected with the connecting rod (6), and then connected and installed through the connecting rod (6) and the swing rod (7). The passage between the swing rod (7) and the swing rod (7) can be freely The rotating pin shaft (8) is connected, and the fork (7) connecting the A-level water pump (2) is installed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com