Polyester printed knitted fabric

A knitted fabric and printing technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problem of single-function knitted fabrics, and achieve the effect of realistic patterns, strong artistry, and delicate layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described in detail below through embodiments and in conjunction with the accompanying drawings.

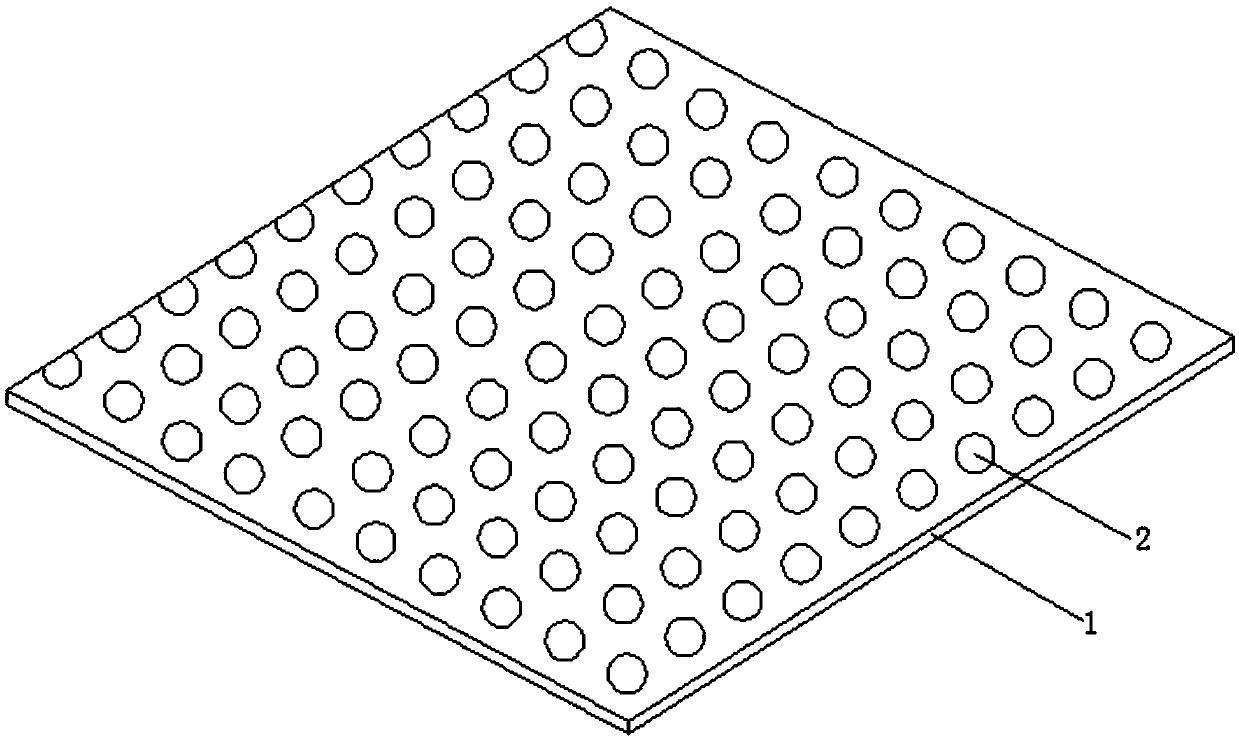

[0011] like Figure 1 ~ Figure 3 As shown, the polyester printed knitted fabric includes a fabric layer 1 and a printing layer 2, and the printing layer 2 is arranged on the fabric layer 1 by flat screen printing, and the printing layer 2 is composed of printing units distributed in a matrix, and the printing units can be It is a variety of flower-shaped units that meet people's aesthetics and can improve people's psychological comfort. It has bright colors, lifelike patterns, delicate layers, and strong artistry. At the same time, the fabric layer 1 has good air permeability.

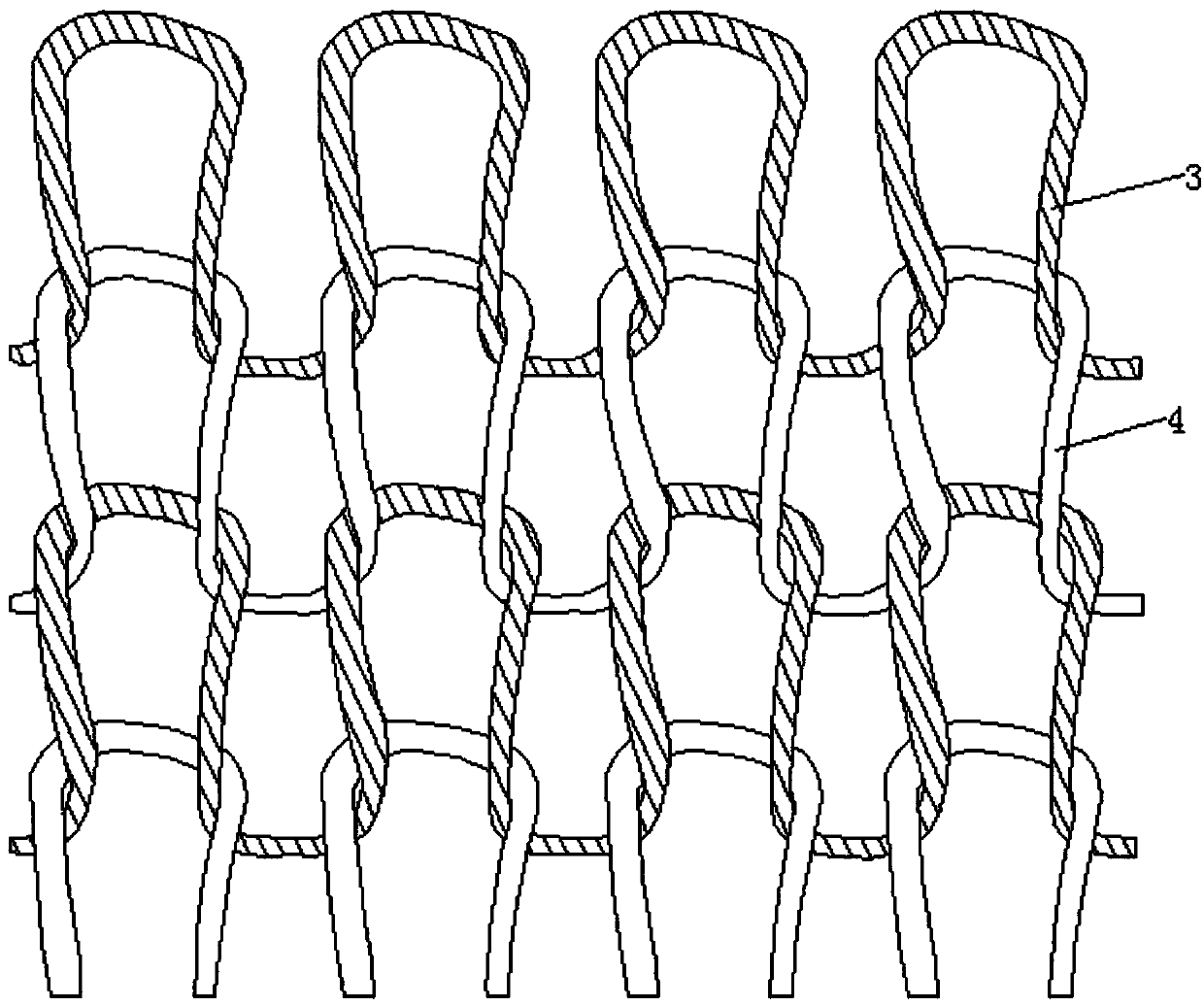

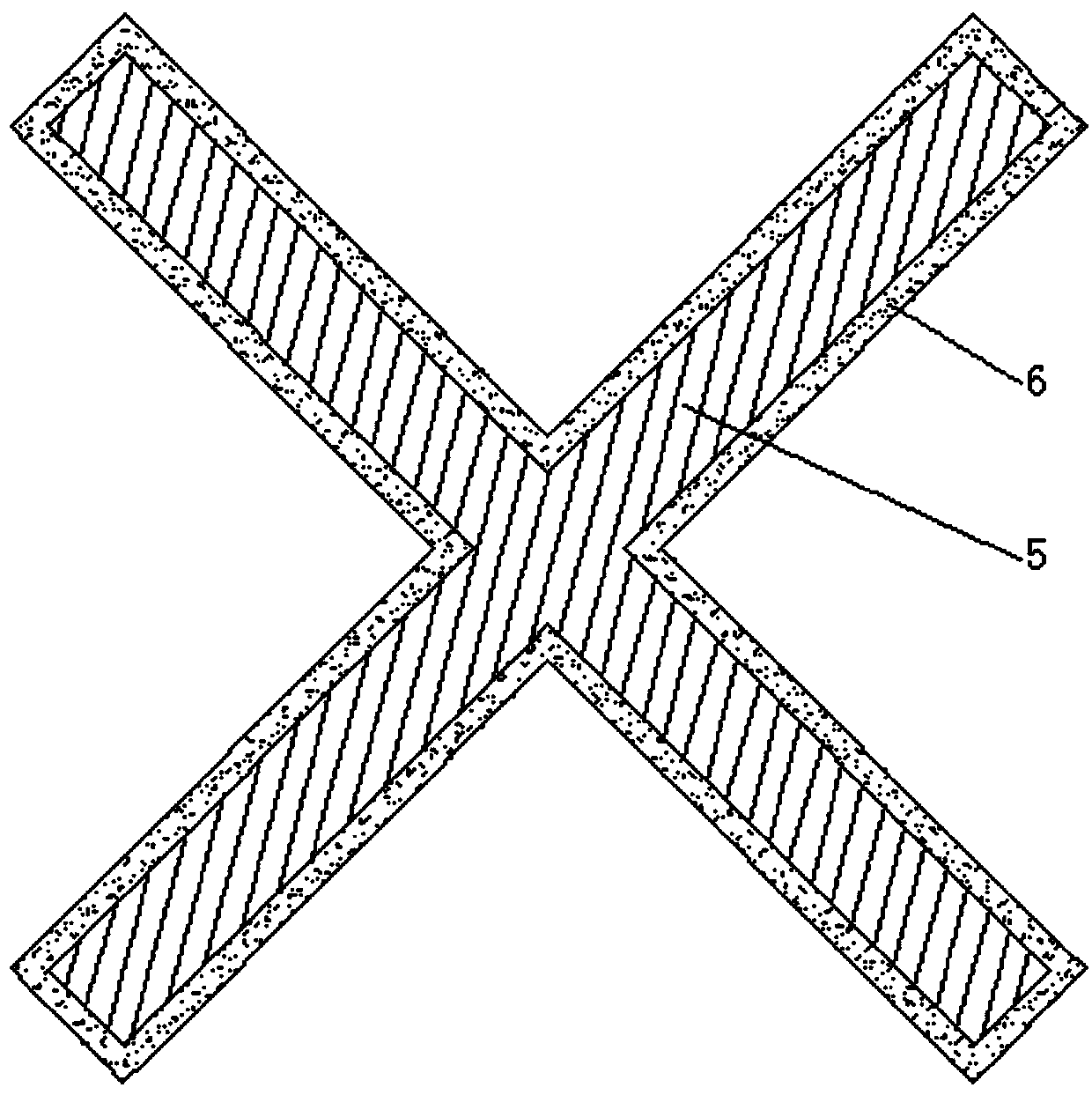

[0012] The fabric layer 1 has a loop structure in which 11.1tex polyester filament 3 and 20D spandex 4 are interwoven, the loop length of the polyester filament 3 is 25cm / 100 stitches, and the loop length of the spandex 4 is 10.5cm / 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com