Sounding pipe parallel limiting device

The technology of a limit device and acoustic tube is applied in the direction of basic structure testing, construction, and basic structure engineering. It can solve the problems of complex parallel limit devices, reduce concrete pouring efficiency, and detect signal distortion, so as to reduce costs and The effect of construction complexity, saving raw materials and material resources and manpower, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

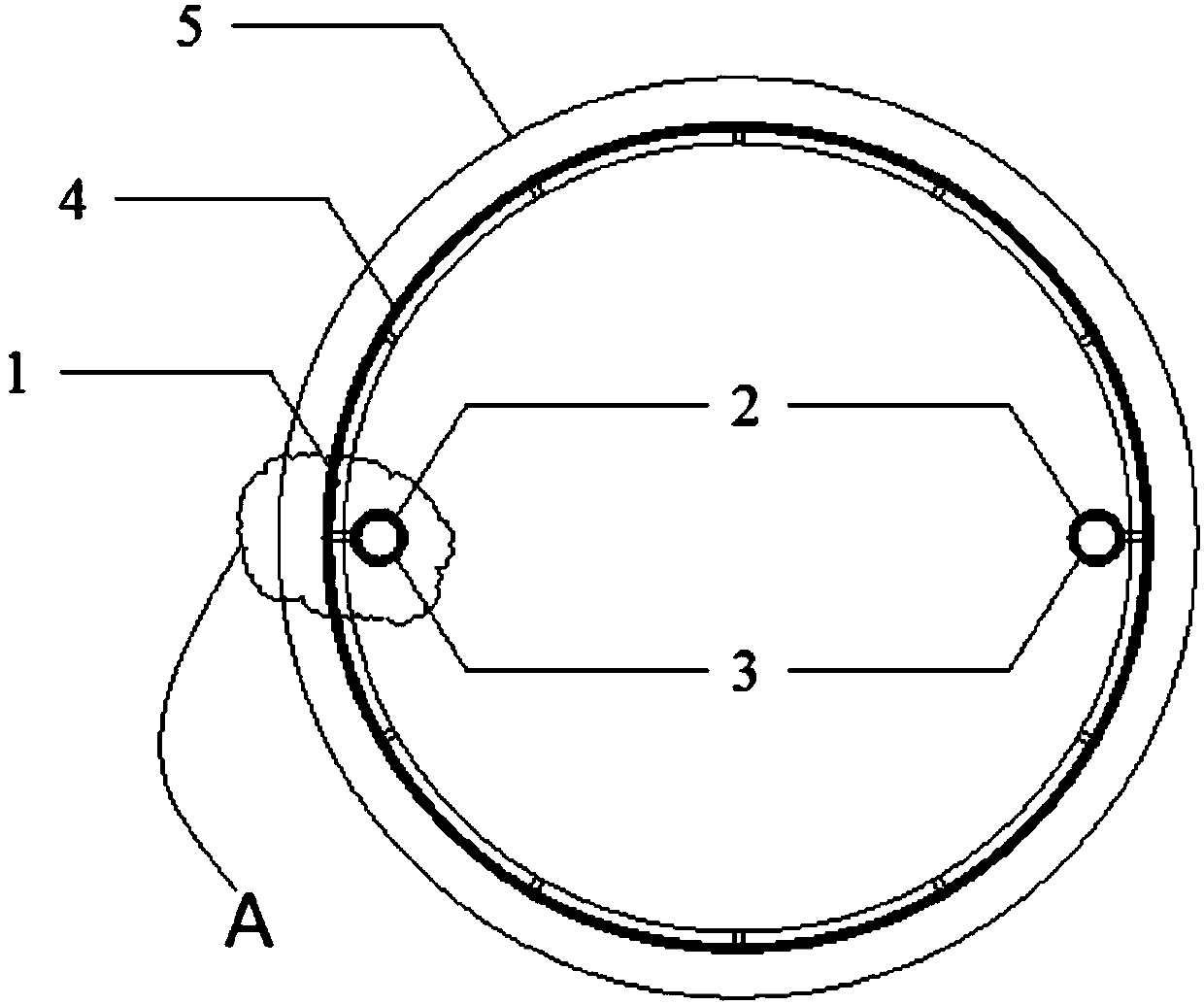

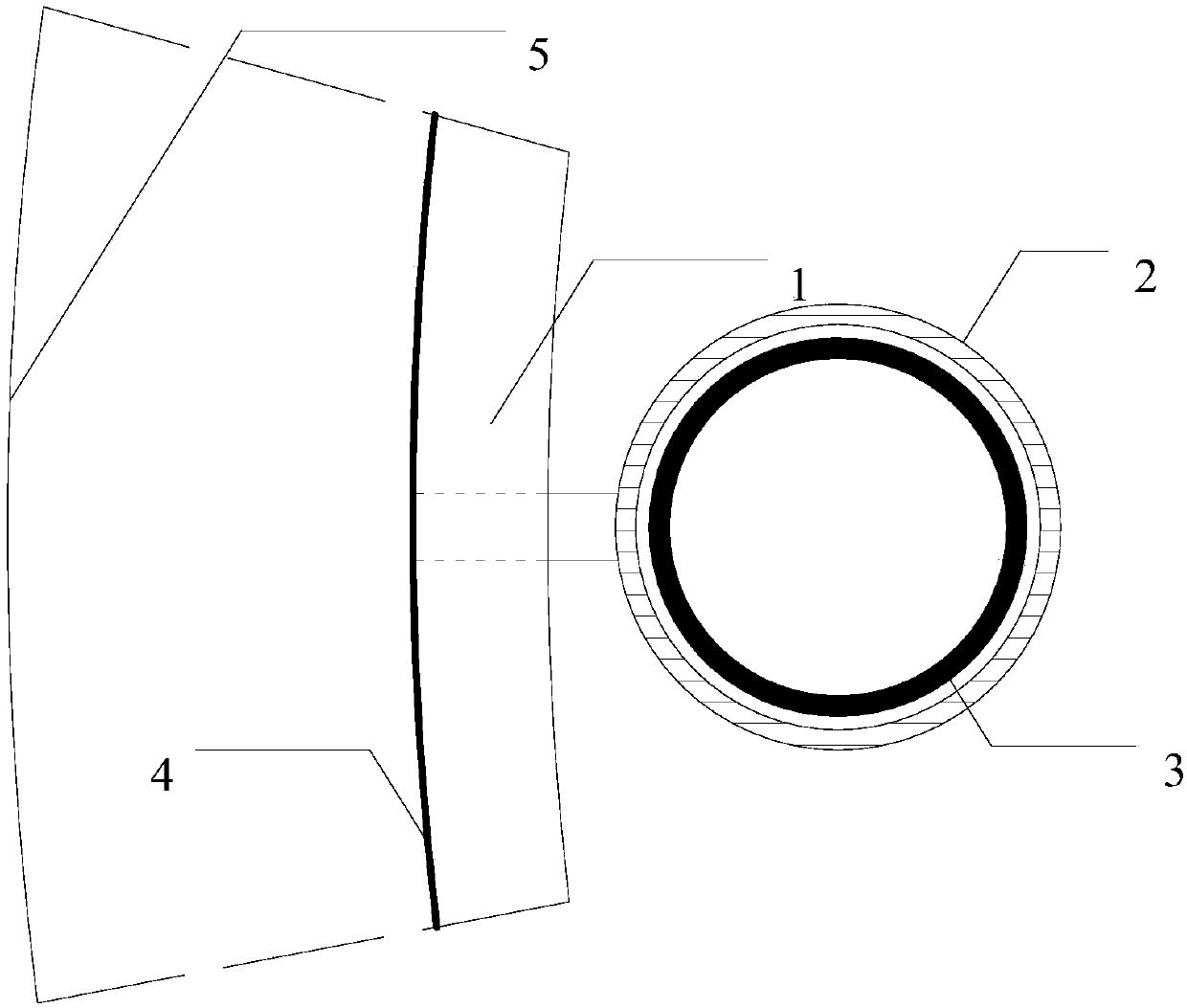

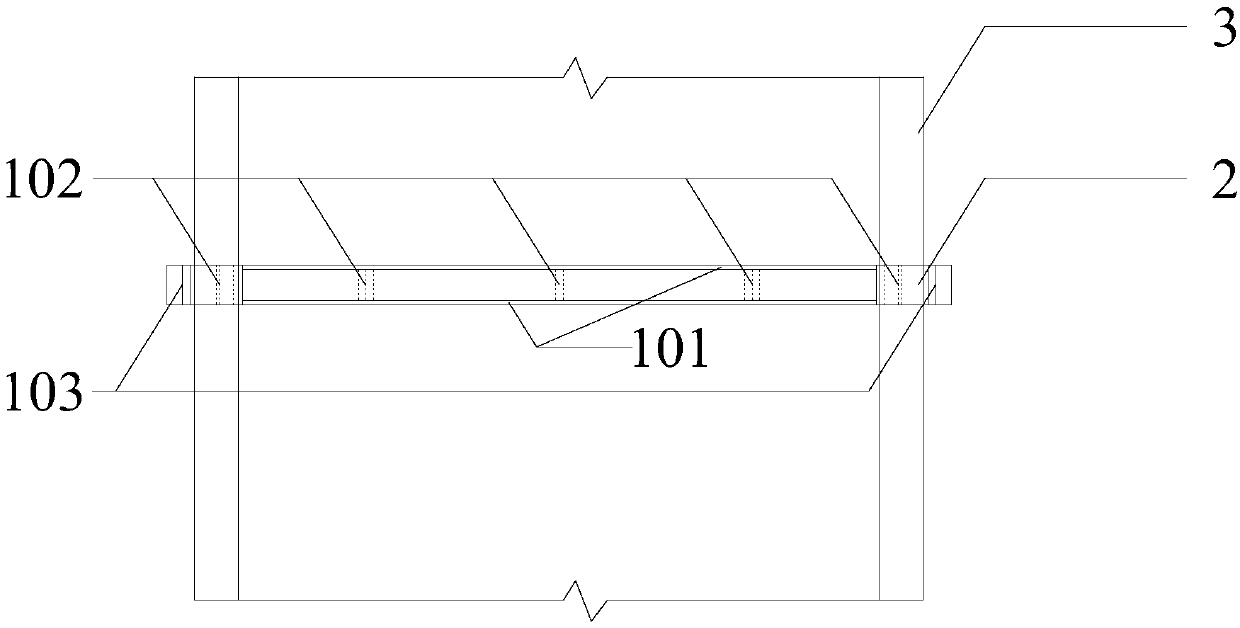

[0045] Such as image 3 and Figure 4 As shown, the parallel limiting device provided in this embodiment includes two sleeves, which are respectively arranged at both ends of a diameter of the double-layer ribbed steel ring;

[0046] The steel ring 1 is composed of the following components by mass fraction:

[0047] Li: 1.9, Cu: 1.1, Mg: 0.9, Zr: 0.08, Fe: 0.12, Si: 0.10, and the balance is Al.

[0048] The reinforcing ribs are composed of the following components by mass fraction:

[0049] C: 0.12, Si: 0.20, Mn: 0.50, P: 0.035, S: 0.050, Cu: 0.20, and the balance is iron.

[0050] The casing 2 is composed of the following components by mass fraction:

[0051] C: 1 part; N: 2 parts, In: 0.8 parts, Pd: 0.08 parts, Zr: 0.9 parts, Ir: 1 part, Rh: 1.5 parts, Fe: 40 parts.

[0052] The material design of the casing, steel ribs and steel ring in this embodiment can effectively improve its rigidity and the rigidity of the overall device after the three are connected, provide a g...

Embodiment 2

[0054] Such as Figure 5 As shown, the parallel limiting device provided in this embodiment includes three sleeves, and the three sleeves are symmetrical about the center of the double-layer ribbed steel ring;

[0055] The steel ring 1 is composed of the following components by mass fraction:

[0056] Li: 2.6, Cu: 1.6, Mg: 1.4, Zr: 0.15, Fe: 0.12, Si: 0.10, and the balance is Al.

[0057] The reinforcing ribs are composed of the following components by mass fraction:

[0058] C: 0.12, Si: 0.20, Mn: 0.50, P: 0.030, S: 0.0:40, Cu: 0.20, and the balance is iron.

[0059] The casing 2 is composed of the following components by mass fraction:

[0060] C: 1 part; N: 2 parts, In: 0.8 parts, Pd: 0.08 parts, Zr: 0.9 parts, Ir element: 1 part, Rh: 1.5 parts, Fe: 40 parts.

[0061] The material design of the sleeve, steel rib and steel ring in this embodiment can effectively improve its rigidity and the rigidity of the overall device after the three are connected, provide a guarantee f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com