Water injection system, ice maker and refrigerator

A technology of water injection system and refrigerator, which is applied in ice making, ice making, household refrigeration equipment, etc. It can solve the problems of water blocking water pipes and inaccurate water addition, so as to avoid high cost, no waste of space, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

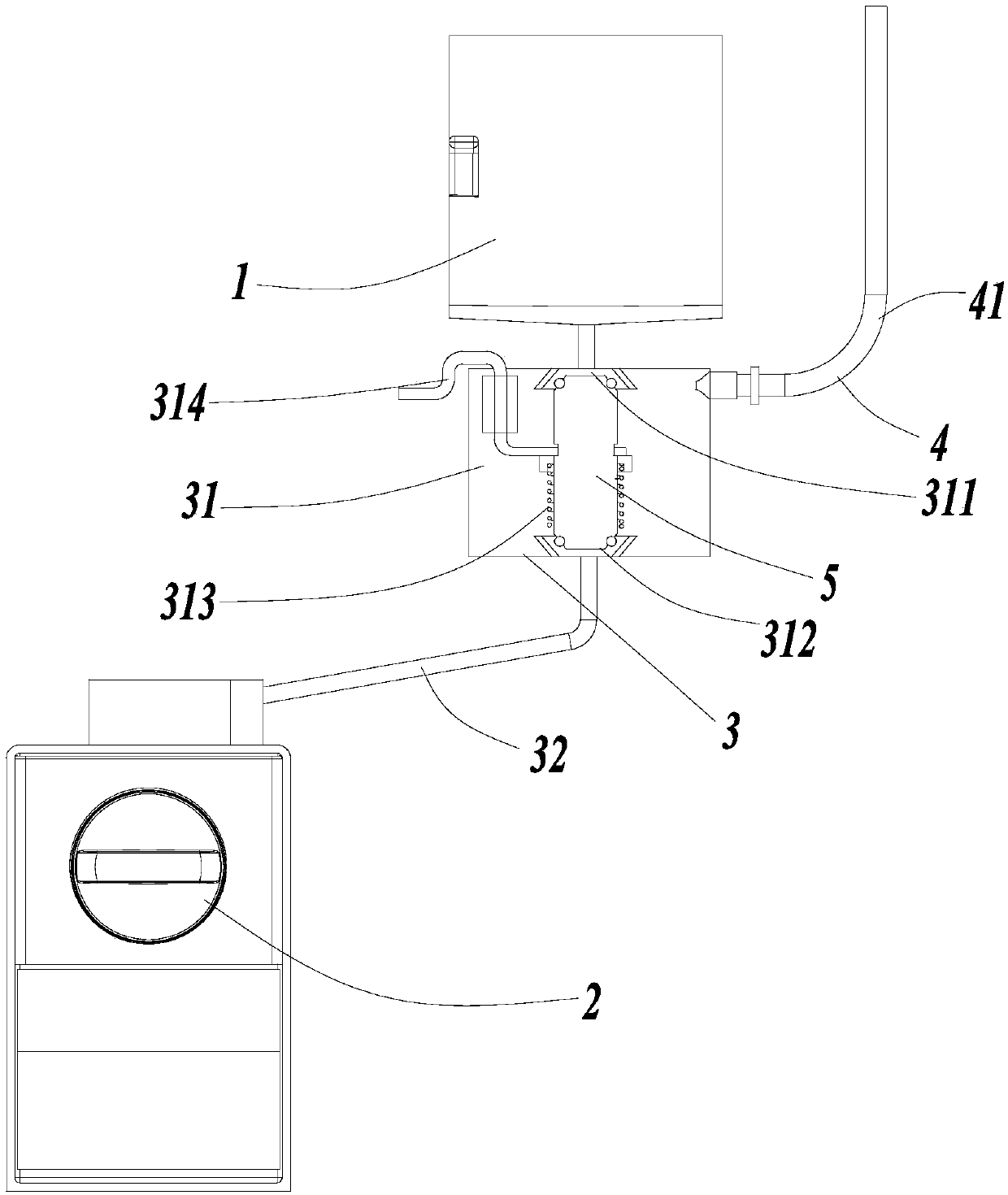

[0030] An embodiment of the present invention provides a water injection system, such as figure 1 As shown, it includes a water storage part 1 and a water demand part 2. The water storage part 1 is used to hold water, and the water demand part 2 is used to receive the water from the water storage part 1. The water storage part 1 and the water demand part 2 pass through water pipes The components 3 are connected, and the water flows from the water storage part 1 into the water demand part 2 by its own power.

[0031] In this embodiment, in order to clearly express the position and direction described in this application, roughly refer to the direction of water flow, since water flows from the water storage part 1 into the water demand part 2 by gravity, so spatially, the upstream direction defines Up and downstream are defined as down, that is, the water storage part 1 is arranged above the water pipe assembly 3 , and the water demand part 2 is arranged below the water pipe ass...

Embodiment 2

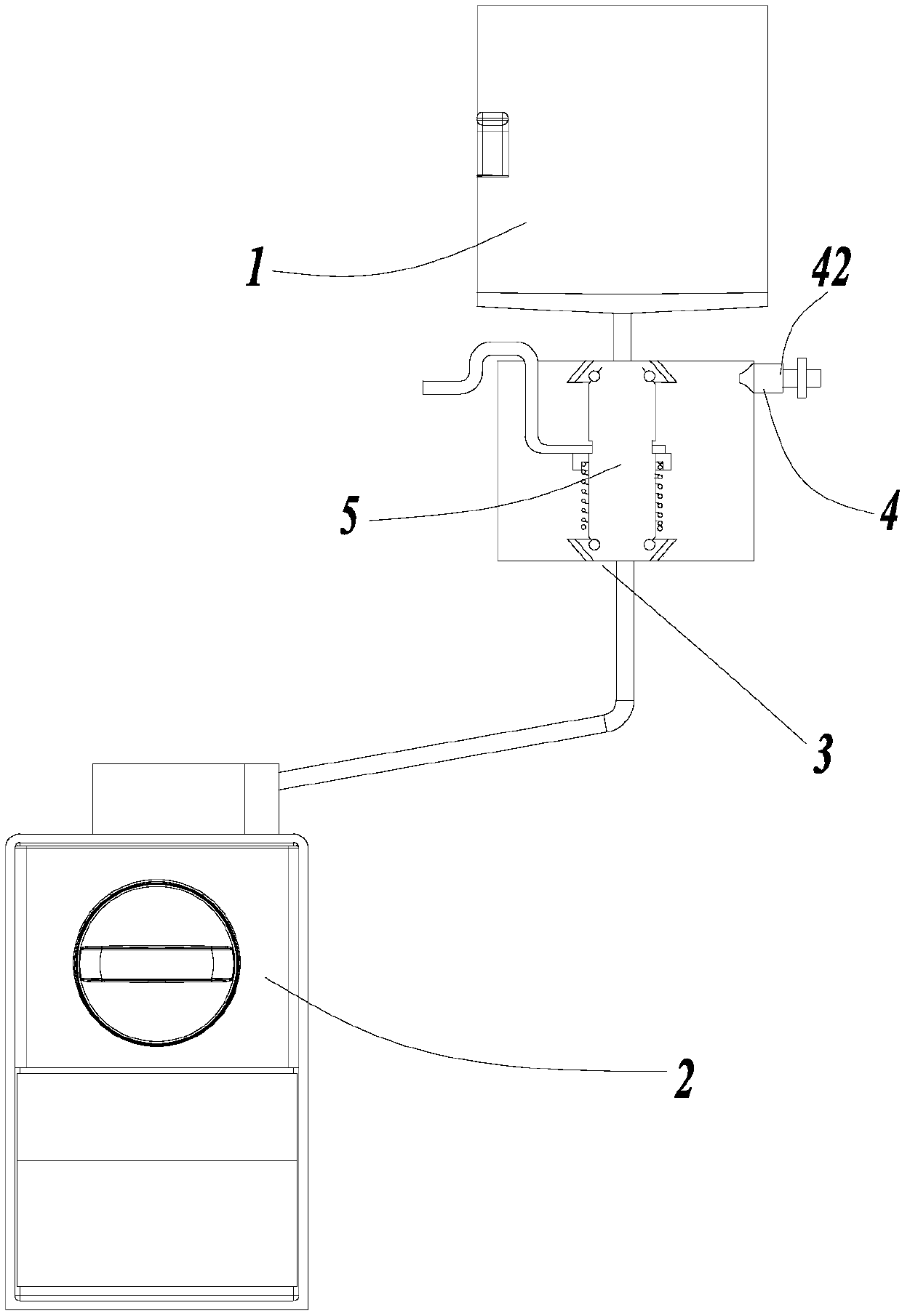

[0050] ginseng figure 2 Another embodiment is provided, and the same reference numerals used in this embodiment as in Embodiment 1 mean structures / components with similar or identical features. The only difference between this embodiment and Embodiment 1 is that the structure of the emptying part 4 is changed. This difference will be introduced in detail below, and other parts that are the same as those in Embodiment 1 will not be repeated here.

[0051] In this embodiment, the air pipe 41 in Embodiment 1 is changed to a one-way valve 42 in view of the state that the water in the water storage part 1 is an external water source, that is, the water storage part 1 is directly connected to the water outlet device with pressure. The one-way valve 42 controls the external air to enter the water flow channel through the air flow channel in one direction, so as to prevent water from flowing into the air flow channel from the water flow channel and overflowing from the emptying part...

Embodiment 3

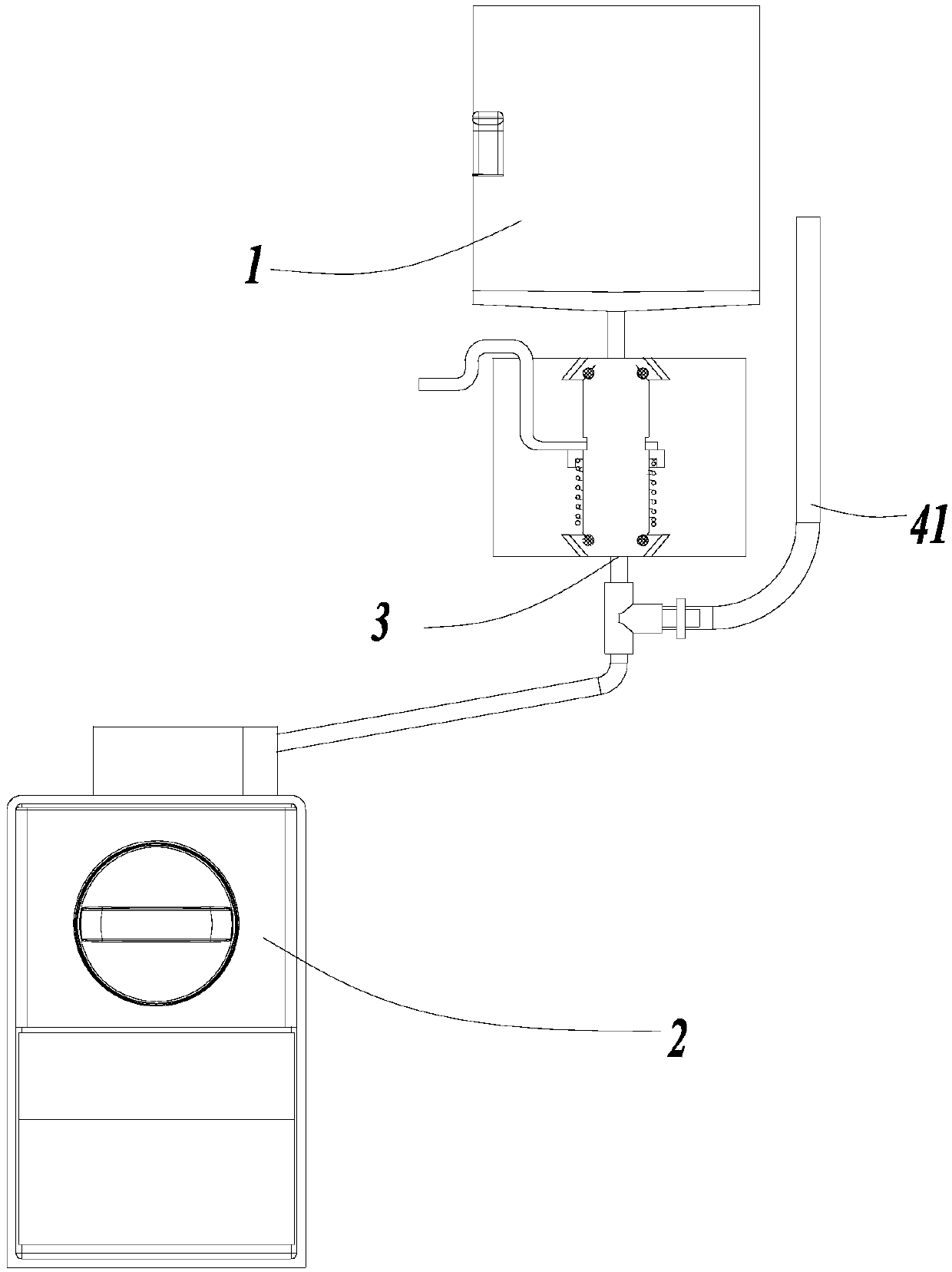

[0055] ginseng image 3 Another embodiment is provided, and the same reference numerals used in this embodiment as in Embodiment 1 mean structures / components with similar or identical features. The only difference between this embodiment and Embodiment 1 is that the position of the emptying part 4 is changed. This difference will be introduced in detail below, and other parts that are the same as those in Embodiment 1 will not be repeated here.

[0056] In this embodiment, the emptying part 4 is arranged on the first water pipe 32 , and the emptying part 4 includes a ventilation pipe 41 . The water in the water storage part 1 is in the state of holding water, that is, the water flows downward under the effect of its own gravity. At this time, the end of the vent pipe 41 is higher than the highest liquid level of the water in the quantitative part 31, so as to prevent the quantitative part from The water in 31 overflows from the air vent. When the water injection system is ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com