Auxiliary device for detecting dragging toughness of tire frame of new energy vehicle in offline detection

A new energy vehicle and auxiliary equipment technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of weak grip of the wheel, hidden danger of tire explosion due to thin tread, day and night loss of pattern depth, etc., to achieve grip The effect of improving soil strength and reducing traffic risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

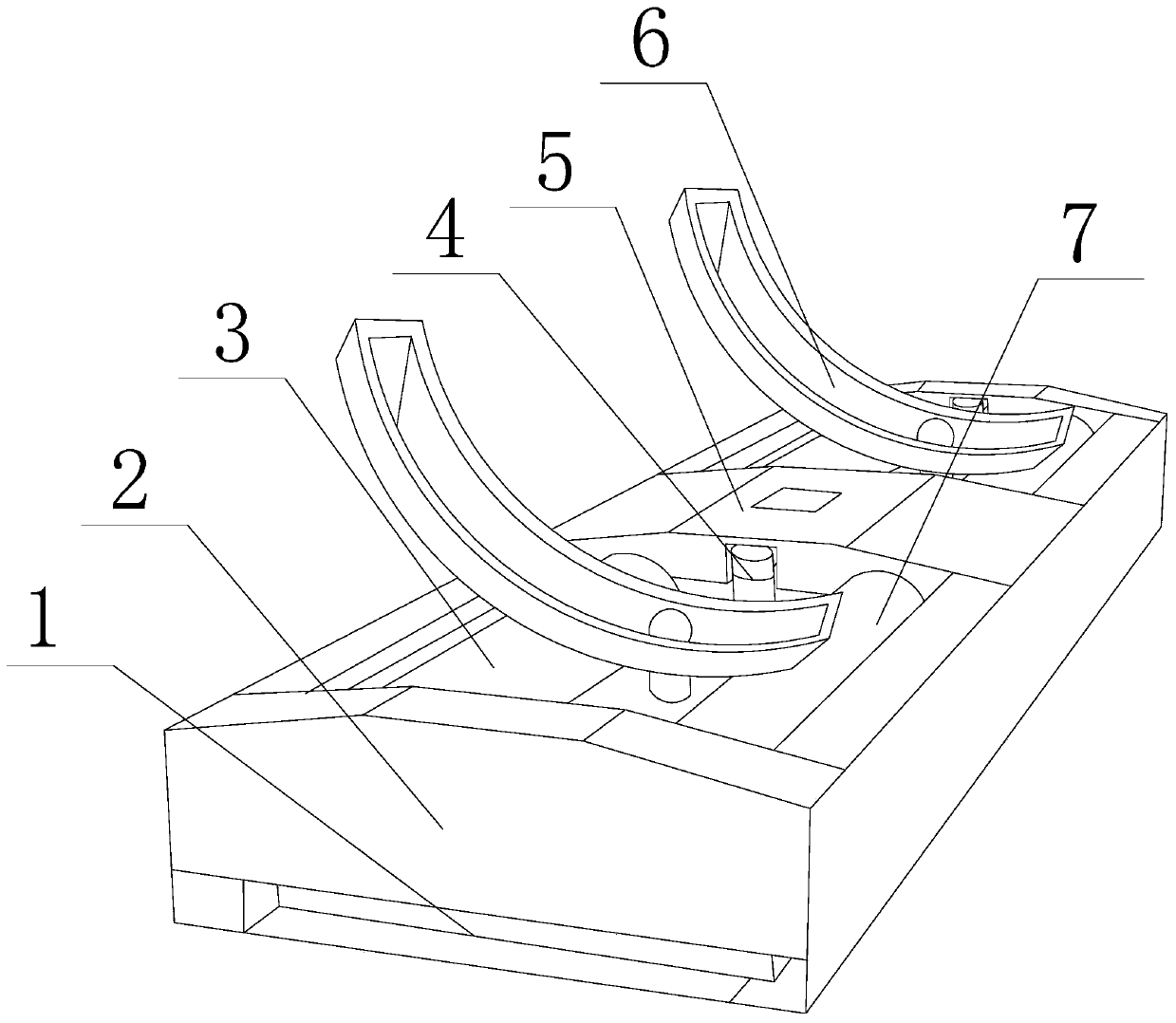

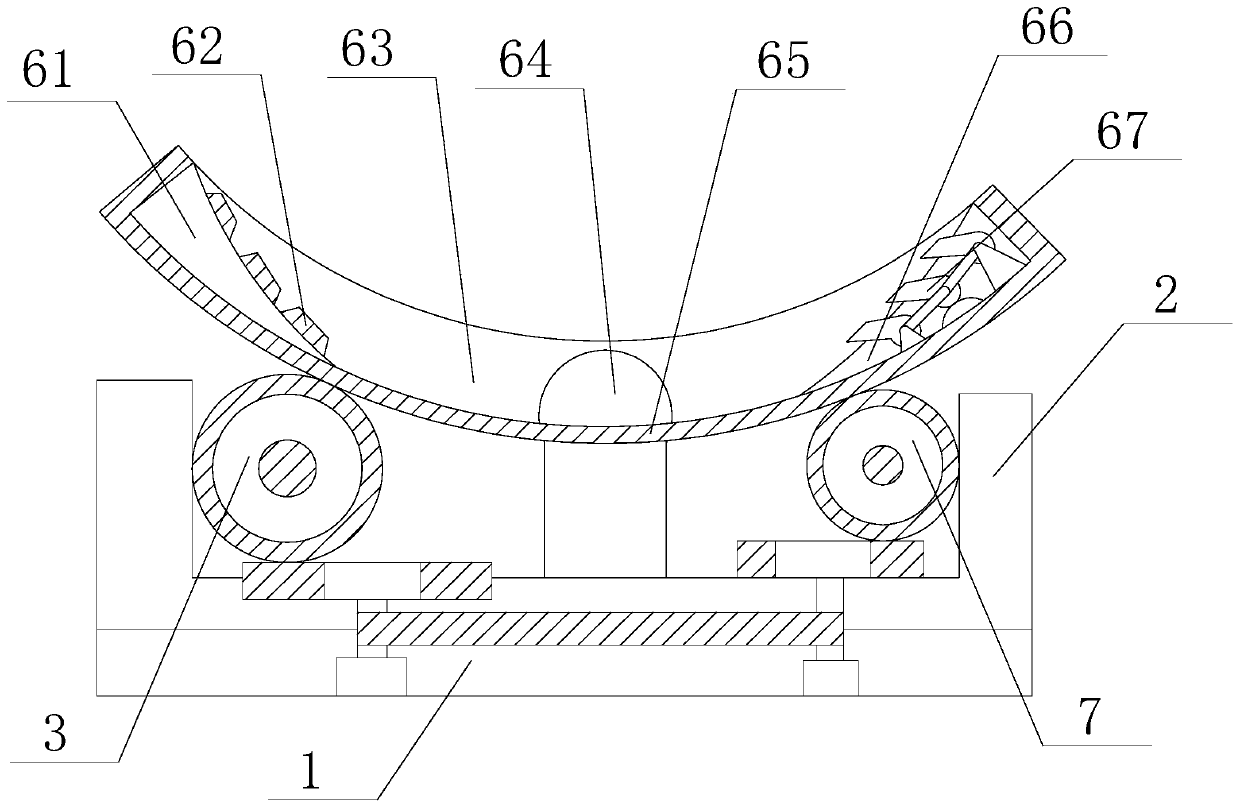

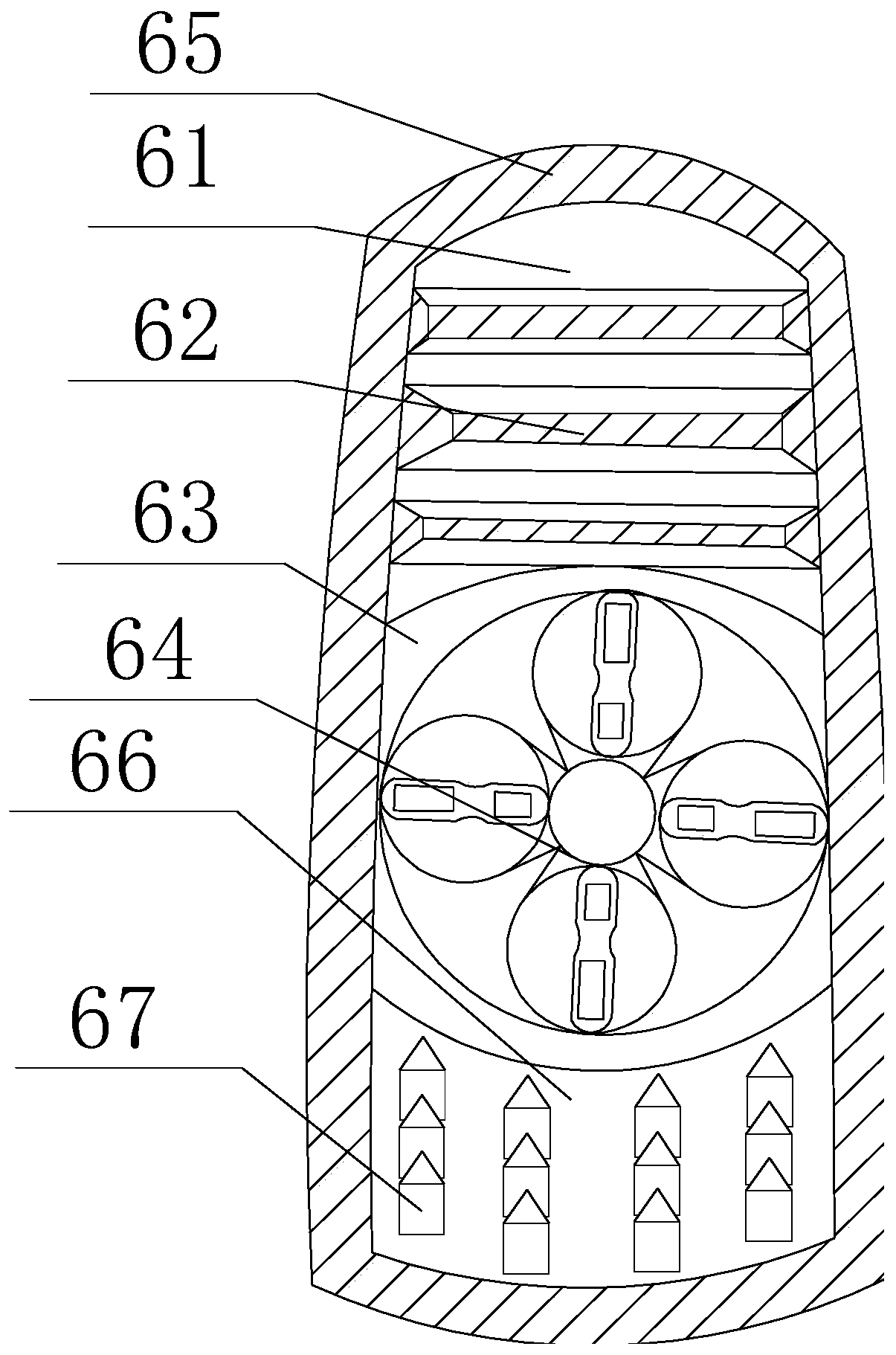

[0028] see Figure 1-Figure 6, the present invention provides an auxiliary equipment for toughness detection of tire frame buckle pulling of new energy vehicles, its structure includes: transmission base 1, double groove shell 2, thick roller 3, hydraulic column 4, chassis spacer Plate 5, half-ring traction mechanism 6, thin roller rod 7, the thick roller 3 and thin roller rod 7 are installed on the left and right upper corners of the transmission base 1, and the half-ring traction mechanism 6 passes through the thick roller The cylinder 3 and the thin roller rod 7 are mechanically connected with the transmission base 1, and the bottom surface of the chassis partition 5 is closely attached to the middle section of the rear side of the double-groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com